There are several reasons why a water bottling company choose to produce its own plastic water bottles:

Cost

36 gram preform is most usually use to produce 1500ml plastic bottle. And 36gram preform just cost $0.056 usually while a 1500ml cost $0.08 or more. It will help you save large number of cost per month. The smallest water bottling line will production 300k piece bottle water.

Produce your own plastic bottle will help you save 1set blow molding machine cost per month.

Freight

Empty bottle not only take room but also easy been crush while freight. It take room about 10times than preform. So that the freight cost is 10times than preform. What is more, the empty bottle easy been crush when freight. But the preform is strong enough to freight without any damage. 1cube can filler 10k piece preform but only filler 1k piece empty bottle.

Sterile

Let us have a look of the short purified water standard for sachet and bottle water.

| NAME | Claim |

| Chroma/degree ≤ one | 5, and shall not show other abnormal colors |

| Turbidity/NTU ≤ | 1 |

| Smell and taste | No odor or odor |

| Visible | Not detectable |

| Pathogenic bacteria (Salmonella, Shigella, Staphylococcus aureus) | NO ALLOW |

In the above form. We can saw that the any bacteria is not allow to detected. But as we know there are a lot bacterias in the air and human being hand. And the water package process can not avoid the human being and air. It is happened in the factory. The factory must have air and human being.

The water been purifier by RO system and mixer with Ozone. It is easy for control its quality. Then the next key control is the bottling process. A lot bottle water company buy the plastic bottle from supplier and freight to water bottling factory. That is a big problem. The freight process is too long time to lead the bottle outside and inside bactrias by air or car.

Heating preform

clean-air blowing making bottle

We strong suggestion water bottling company making the plastic bottle in water bottling factory. And fast use the plastic bottle to washing filling and capping water so that fast sealing. It can reduce the time for the plastic bottle touch air.

What is the more important. The plastic bottle making process have two step. First is high temperature heating the preform which is also kill bacteria of the preform. Second is blowing clean air into the preform to making it into the plastic bottle.

After making the plastic bottle. Fast sending it to ozone water push washing. Then filling water and capper to finished the sealing the bottled water. That process can reduce the time bottle touch air and reduce bacterias inside the bottle water.

Also, the water with ozone filler into the bottle. It also can keep non-bactrias for the inside of the finished sealing bottle.

Storage room

The empty bottle take more storage room. And buy empty bottle from supplier may not considerable about how many cost everyday. A water bottling company at least need use 10000 piece empty bottle which take about 10cube storage room. But water bottling company need storage at least one day use empty bottle. If storage 1week empty bottle that need a 70cube storage room.If a water bottling company storage preform that just a 7cubes storage room.

Your own unique plastic bottle design

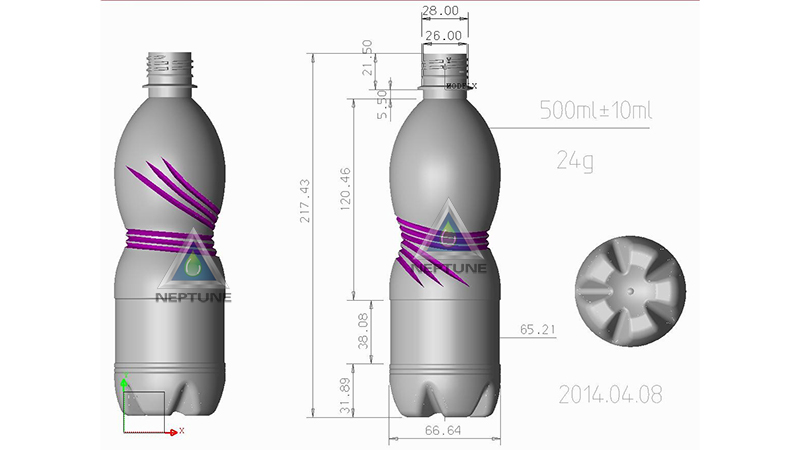

Buy plastic bottle from supplier that bottle is universal. And your bottle may same with your competitor. If you blowing and making your own plastic bottle that you can have unique design. And it just need change a blow mold so that can produce a different shape or volume plastic bottle.

What is more, you can selling your plastic bottle to other. Even they asking a unique bottle different with you, if large order, you can change a blow mold so that can reach their inquiry.

Own yourself pet bottle blowing machine have a lot advantage. It is the best choice and give you a lot extra chance to expend business.