CM-A4 Automatic water bottle making machine is a reliable and efficient solution for businesses seeking high-quality PET plastic bottle production.

fOB PRICE USD 35850

What this price included?

| NO | NAME | QC |

| 1 | CM-A4 Automatic Blow Molding Machine | 1SET |

| 2 | CM-A4 Preform automatic unscrambler | 1SET |

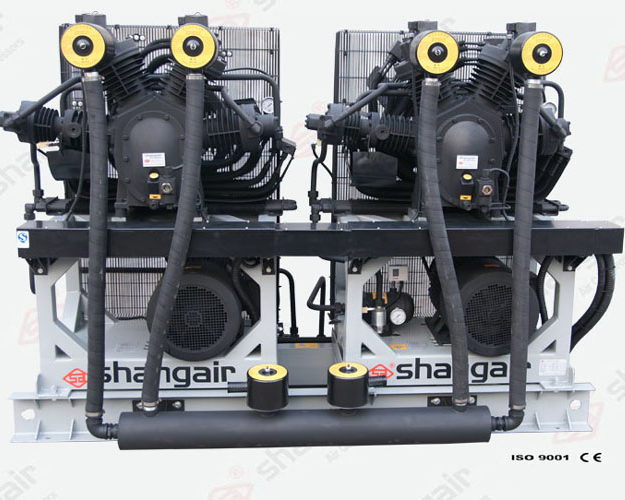

| 3 | 2.4m3/min ,30Kg HP Air Compressor | 1SET |

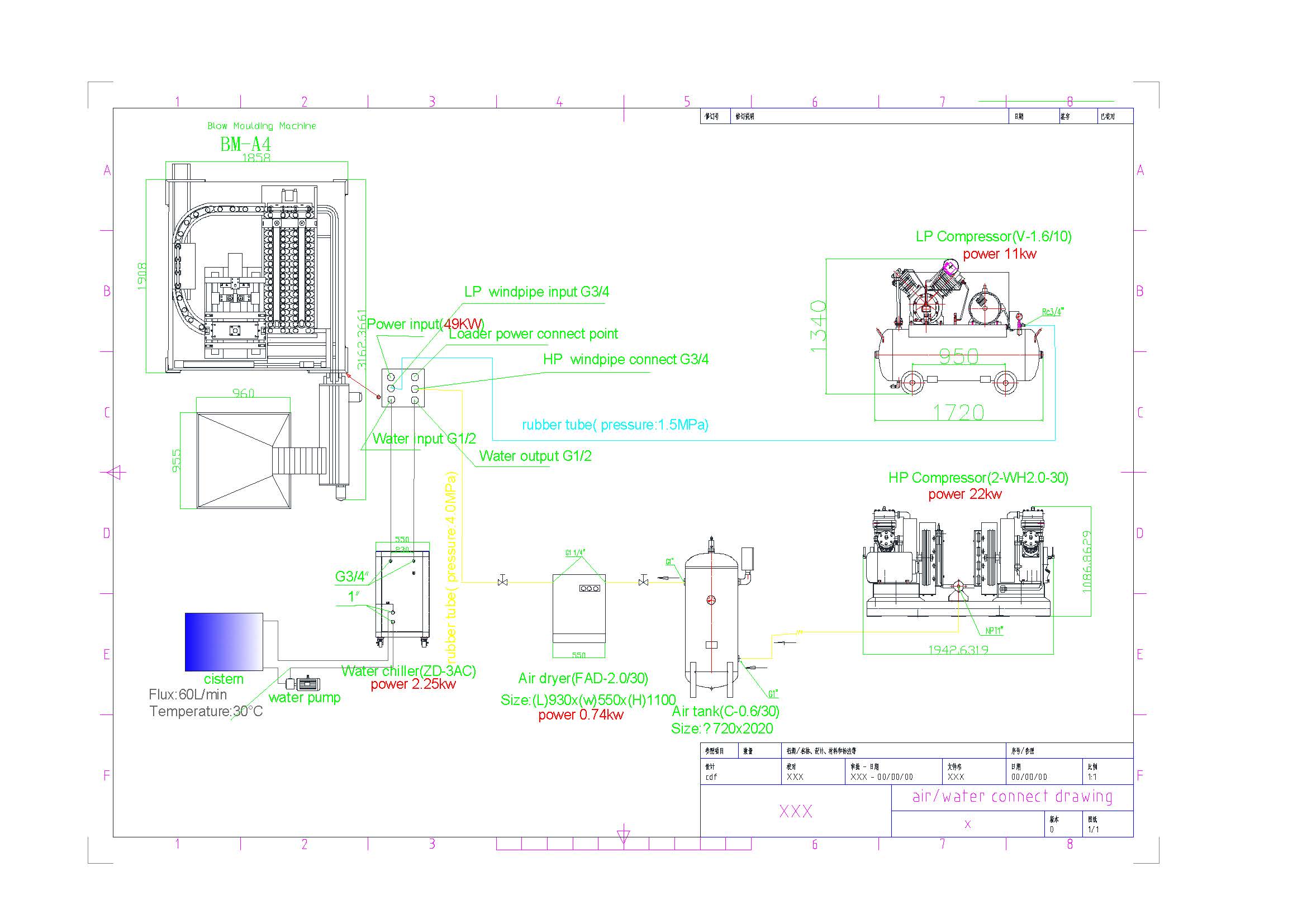

| 4 | 2.0m3/min ,10Kg LP Air Compressor | 1SET |

| 5 | 2.0m3/min ,30Kg Air Dryer(2 Air filters) | 1SET |

| 6 | 0.6m3 30Kg Air Tank | 1SET |

| 7 | 3HP Mould Air Chiller | 1SET |

| 8 | High-low pressure tracheal connection | 1SET |

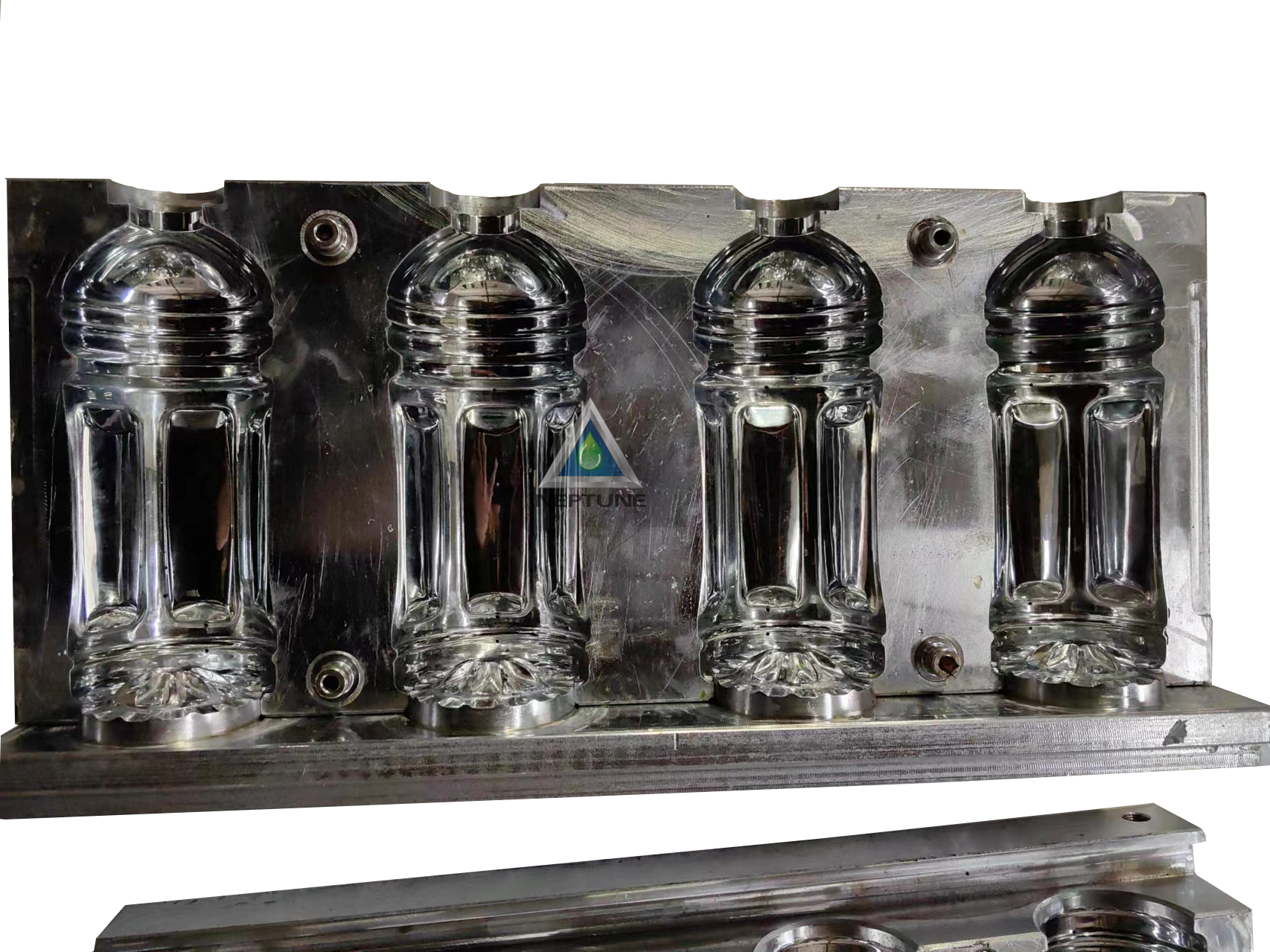

| 9 | Four cavity Blow Mold (250-2000ml) | 1SET |

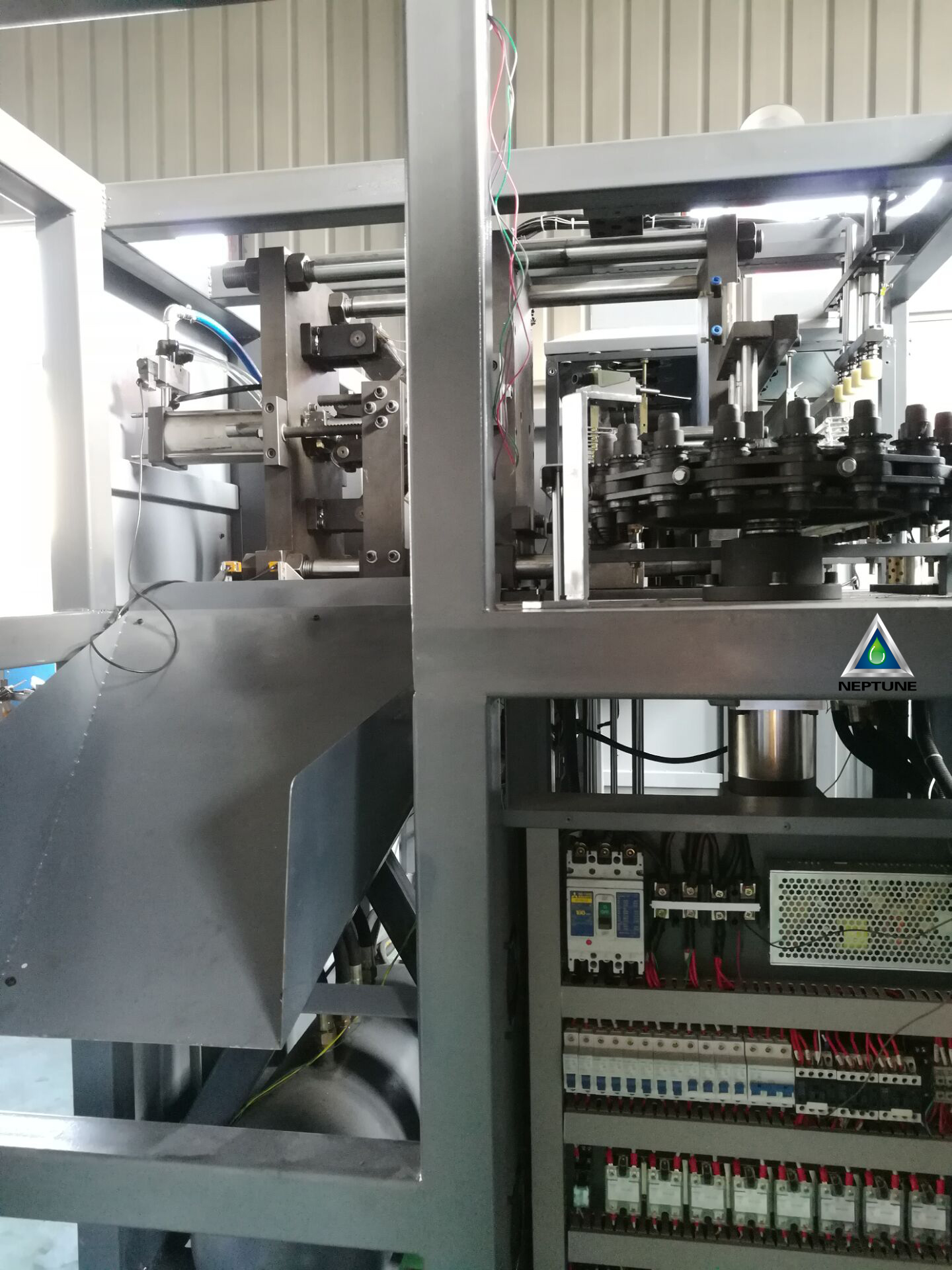

CM-A4 Water Bottle Making Machine

Full Automatic CM-A4 Water Bottle Making Machine stands as a pinnacle in PET plastic container and bottle production, catering to diverse shapes and applications. This cutting-edge machine is extensively utilized for manufacturing various types of plastic bottles, including carbonated beverages, mineral water, pesticides, oils, cosmetics, wide-mouth containers. Its versatile design and advanced features make it an ideal choice for businesses across different industries.

🌐 Applications:

🥤 Ideal for Beverage Manufacturers: Perfect for producing PET bottles for a range of beverages, including water, juices, sodas, and more.

🏭 Versatility Across Industries: Adaptable for diverse industries requiring PET bottles. Transition to an automatic bottle-making machine for increased efficiency.

Key Features:

- Versatile Production: The plastic bottle maker accommodates the production of PET containers and bottles in diverse shapes and sizes, providing flexibility for a range of applications.

- Wide Application Range: Suitable for manufacturing carbonated bottles, mineral water bottles, pesticide containers, oil bottles, cosmetics packaging, wide-mouth bottles, and hot-fill bottles.

- Fully Automatic Operation: The CM-A4 operates as a fully automatic system, streamlining the manufacturing process and enhancing efficiency.

- Advanced Technology: Leveraging state-of-the-art technology, this machine ensures precision and reliability in the production of high-quality PET bottles.

- Broad Industry Usage: Widely adopted across industries, including beverage production, cosmetics, and pharmaceuticals, the machine caters to the diverse needs of businesses.

- Customizable Design: The machine’s design allows for easy customization, adapting to specific production requirements and bottle specifications.

- User-Friendly Interface: Equipped with a user-friendly interface, the machine facilitates easy operation, reducing complexities in the manufacturing process.

- Durable Construction: The CM-A4 machine for making bottle water is built with durability in mind, ensuring a robust and long-lasting performance to meet the demands of continuous production.

CM-A2

$27240CM-A4

$35850CM-A6

$639007 main Auxiliary equipment

1.High pressure air compressor

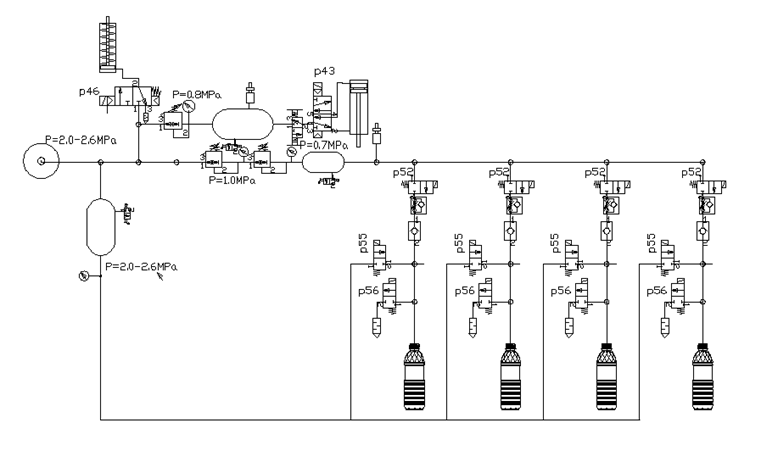

Blowing Process: During the blowing process, the compressed air is utilized to stretch and shape the heated preform into the desired bottle shape. The high-pressure air is injected into the preform, expanding it to conform to the mold cavity.

| 1 | Model | 2-09SH-1540T |

| 2 | Exhaust volume (Nm3/min) | 2.4 |

| 3 | Exhaust pressure (Mpa) | 4.0 |

| 4 | Motor power(kw) | 30KW |

| 5 | Weight | 1120KG |

| 6 | Size (LWH) | 2350×1100×1650 |

2.Low pressure air compressor

Mold Opening and Closing: The high-pressure air compressor plays a role in the operation of mechanisms that open and close the blow mold. It ensures efficient and controlled movements during the molding process.

| 1 | Air compressor | 2.4M3/30KG |

| 2 | Volume | 2.4 |

| 3 | Pressure | 30 |

| 4 | Speed | 600 |

| 5 | Power | 22 |

| 6 | Overall Dimension | 2200*960*1500 |

| 7 | Weight | 1120 |

Why fit Nanjing Shangair brand Air compressor

Founded in 1999, Nanjing Shangair is a high-tech enterprise take technological innovation as the driving force, providing high-efficiency, energy-saving, stable and durable mid-to-high-end air compressors and advanced air compressing solutions to customers around the world.

In a plastic bottle maker machine, air filtration, air drying, and air storage (tank) serve essential functions to ensure the quality and efficiency of the bottle production process. Here’s a breakdown of their functions:

3.Air filter

- Function: The air filter is responsible for purifying the compressed air by removing impurities, particles, and contaminants.

- Importance:

- Ensures clean and contaminant-free air, preventing damage to pneumatic components.

- Protects the quality of PET material during the preform heating and blowing stages.

- Enhances the longevity and reliability of the machine by preventing clogging and wear.

4.Air dryer

- Function: The air dryer removes moisture or humidity from the compressed air to prevent condensation.

- Importance:

- Reduces the risk of water droplets forming in the air lines, which could affect product quality and damage equipment.

- Prevents corrosion of pneumatic components, ensuring long-term reliability.

- Maintains consistent air quality, crucial for the blowing process and final product.

5.Air tank

- Function: The air tank stores compressed air, providing a reservoir for immediate use during high-demand periods.

- Importance:

- Ensures a stable and consistent supply of compressed air, even during peak production.

- Helps balance air supply and demand, reducing fluctuations and maintaining optimal pressure.

- Minimizes the load on the air compressor by storing excess air during low-demand periods.

These components work together to create a reliable and efficient compressed air system for the blow molding machine, contributing to consistent product quality, equipment durability, and overall operational efficiency.

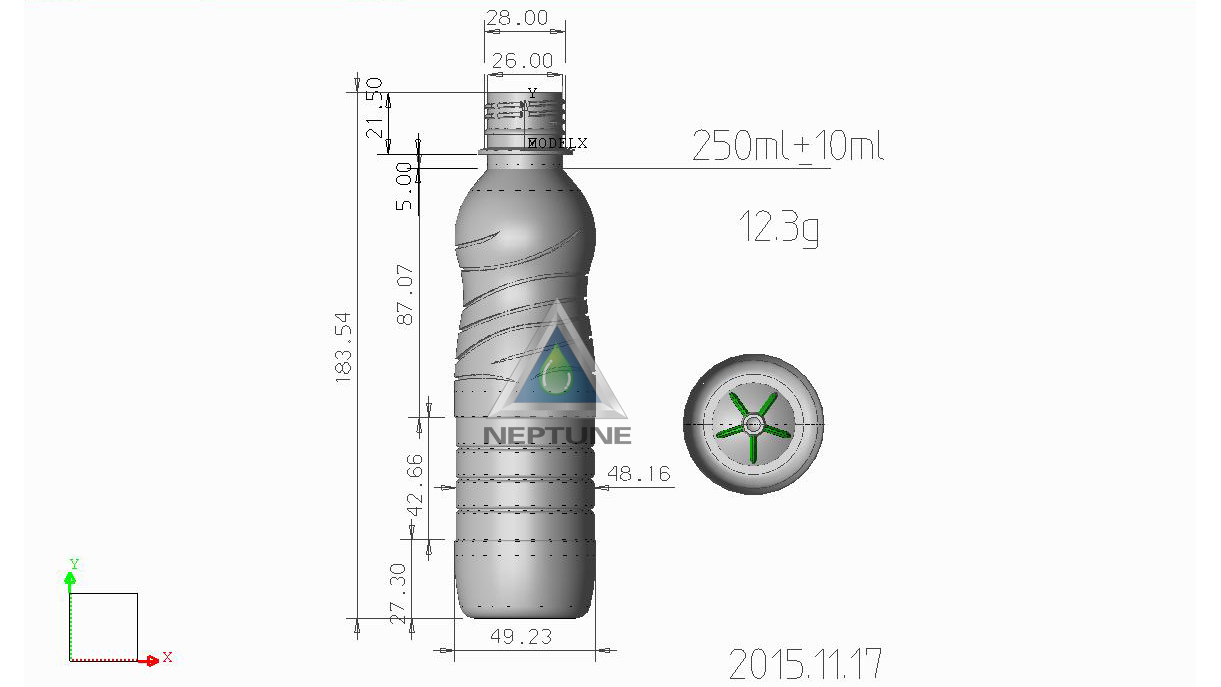

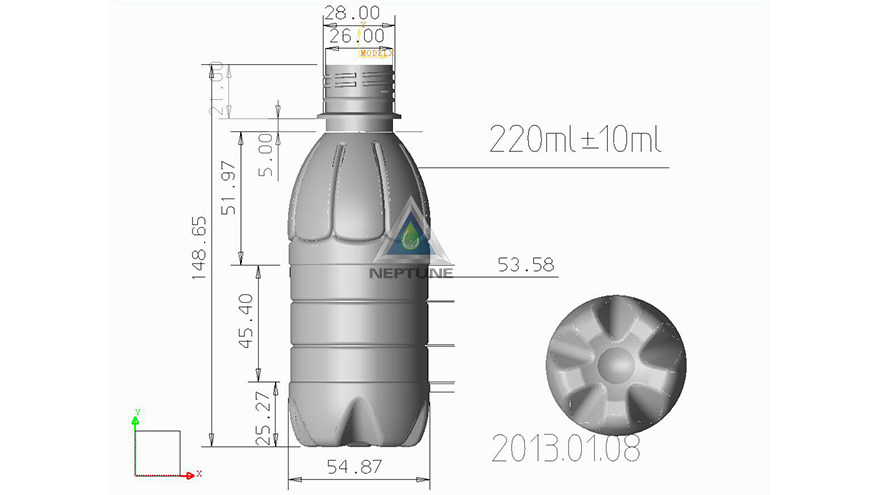

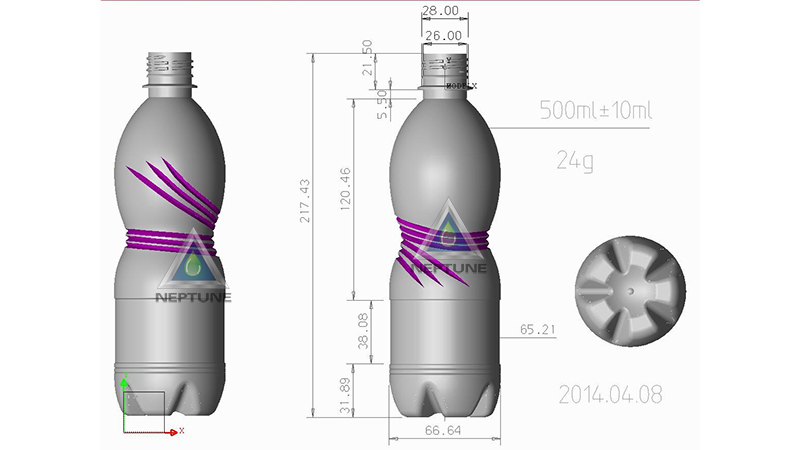

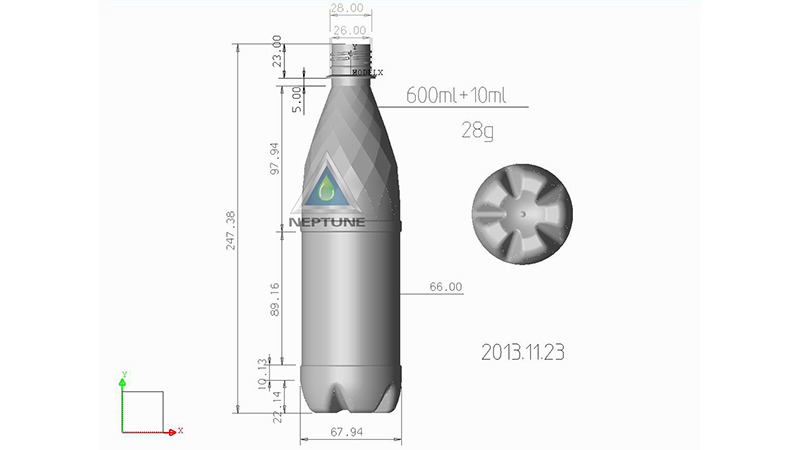

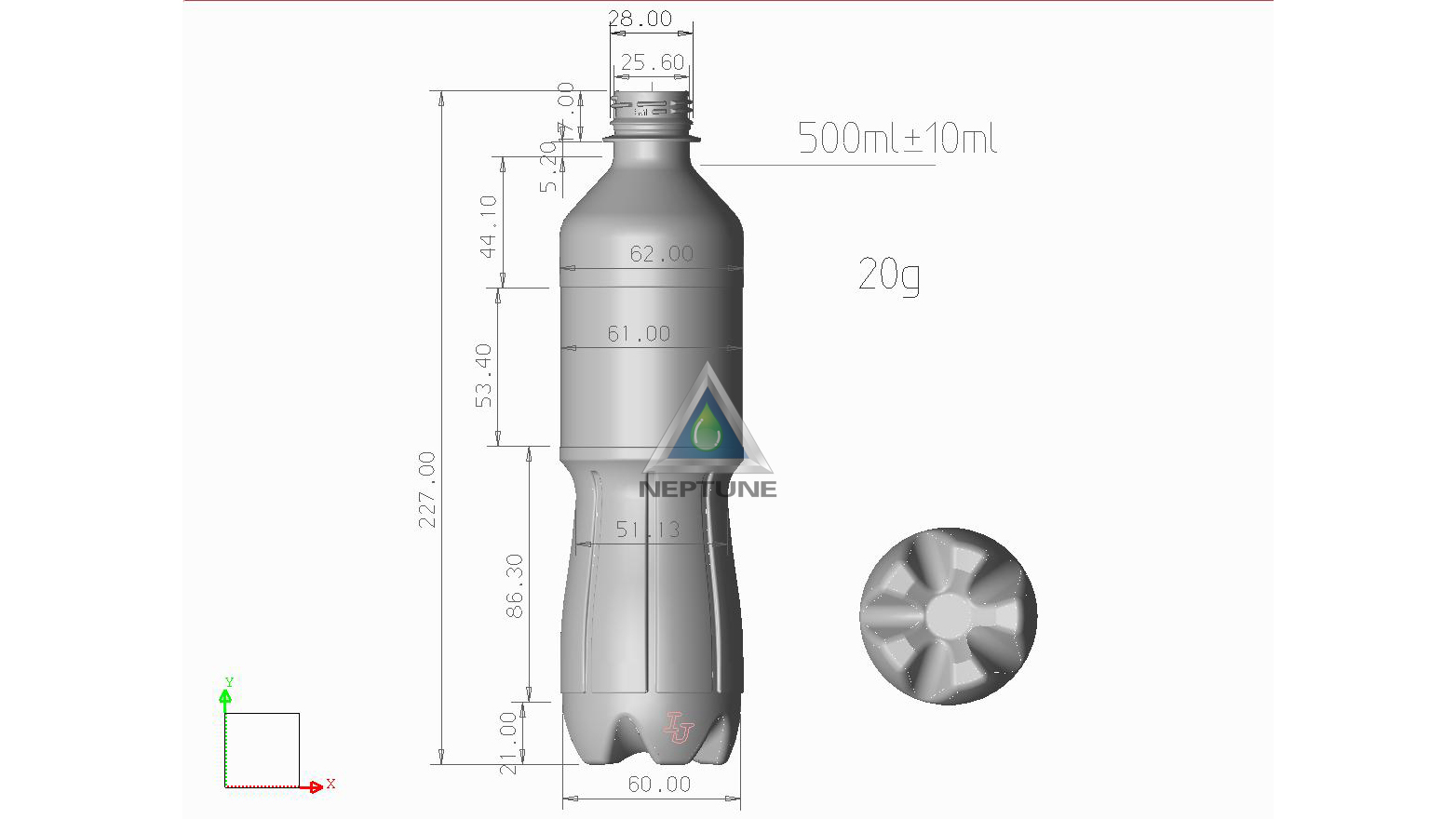

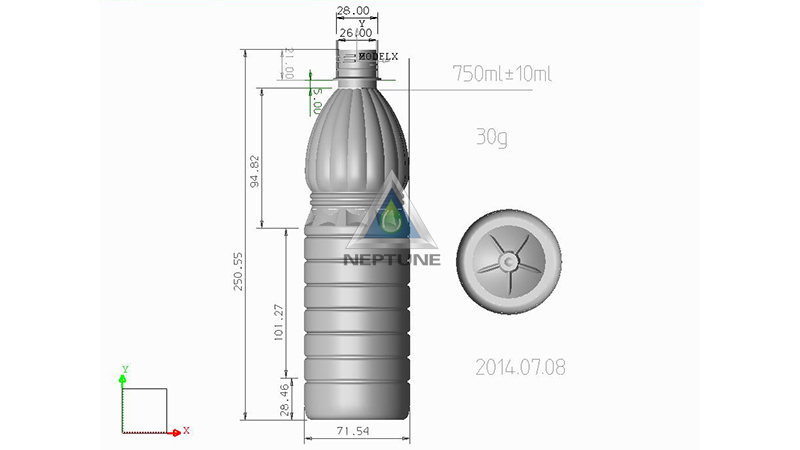

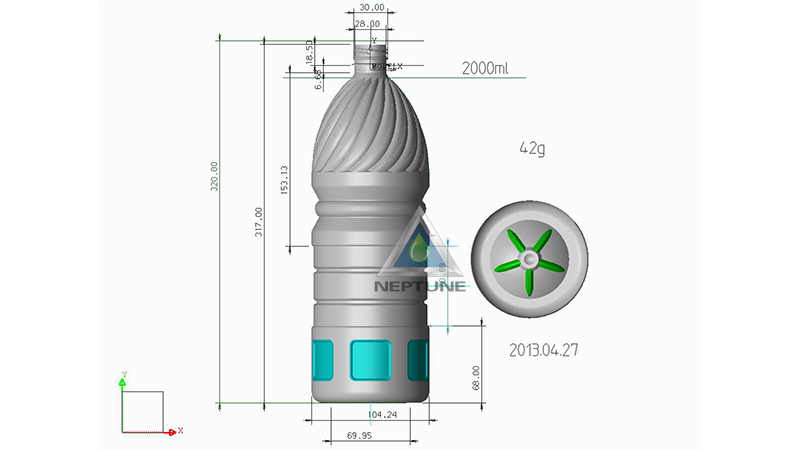

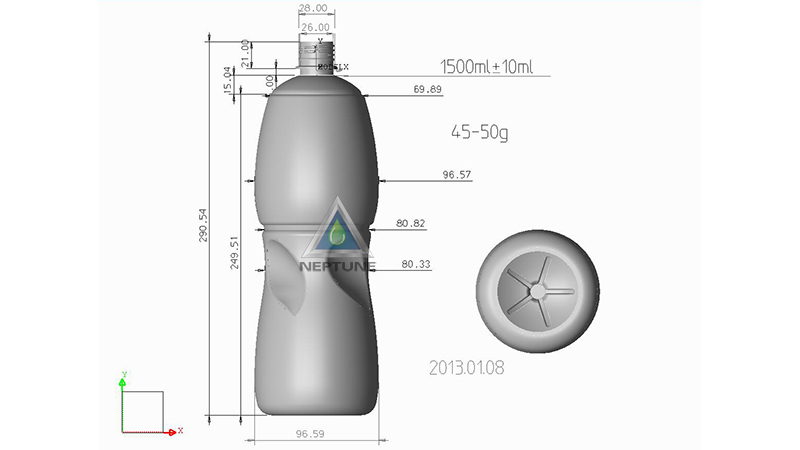

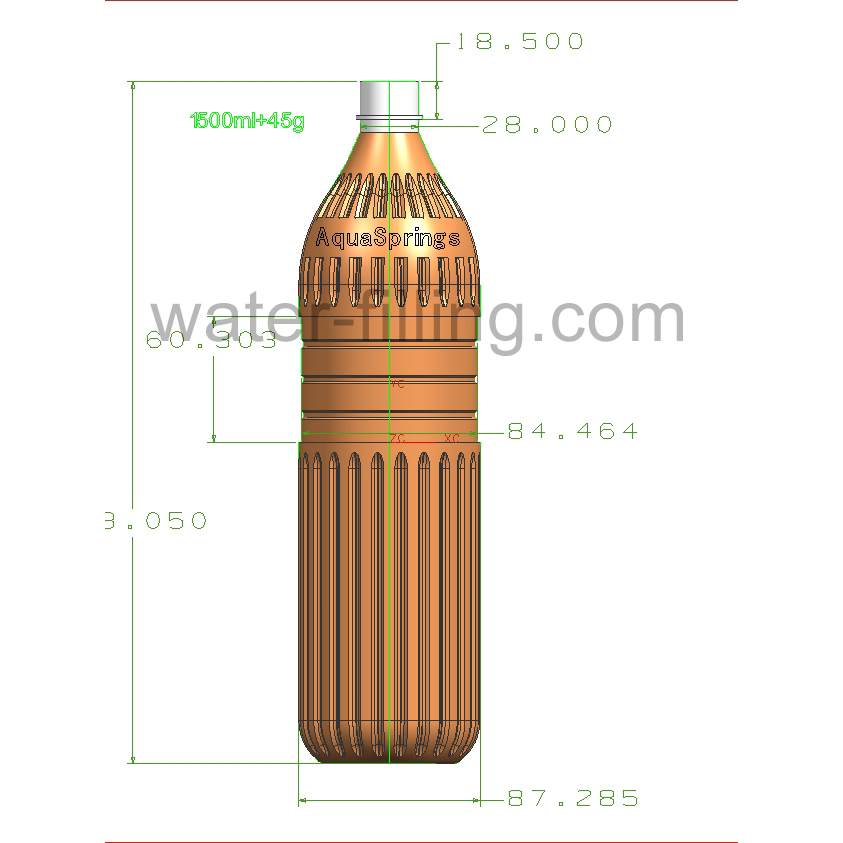

6.Blow Mold (4cavity)

- The blow mold is a hollow cavity or mold shape that defines the final shape and size of the plastic bottle.

- It receives the heated preform and shapes it through the application of high-pressure air, forcing the plastic against the mold walls.

- Determines the design, dimensions, and features of the finished bottle, including neck size, body shape, and base configuration.

Quality Assurance: The precise design of the blow mold ensures the accurate replication of bottle features, meeting quality standards.

These components work together to transform a heated preform into a finished plastic bottle, ensuring accuracy, efficiency, and the overall quality of the manufacturing process.

7.Mold Chiller

Function:

- The mold chiller is a cooling system associated with the blow mold.

- It helps maintain the temperature of the mold at an optimal level during the blow molding process.

- Cooling is essential to solidify and set the plastic material in the desired shape quickly, improving cycle times and production efficiency.

- Prevents overheating of the mold, ensuring consistent and accurate bottle formation.

Cycle Time Optimization: Efficient cooling with the mold chiller allows for faster cycle times, increasing overall production output.

Consistency: Proper temperature control ensures uniform bottle thickness and minimizes defects in the final product.

What benifit from Making Your own plastic bottle?

Many bottled water companies opt to blow their plastic preforms and purchase preforms as materials. Preforms are sturdy, compact, and incur minimal freight costs while being less prone to damage during transportation. They also occupy less space, with one paper box accommodating 500 preforms, and a single container holding 1 million preforms. In contrast, empty plastic bottles require more room, with one container fitting only 100,000 pieces. Choosing preforms over plastic bottles results in substantial cost savings in freight expenses.

Manufacturer Plastic Bottle Save Freight Cost

Some bottled water company buy plastic bottle from plastic bottle maker company. The plastic bottle inside is empty which easy damage during the freight. What’s more, it is take room which freight cost high.

The empty plastic bottle will touch too long air during the freight. The air is an pollution for food indurstry.

Own an bottle making machine is necessary for most bottle water company. It have three advantage. Save freight cost, reduce bottle compression deformation and reduce the pollution by freight.

- Optimizing Empty Space: Manufacturing the bottles on-site helps utilize empty spaces efficiently, reducing storage costs and maximizing available room.

- Preventing Bottle Damage: Empty bottles, especially without contents, can be prone to crushing if stacked. By producing them close to the bottling site, companies can minimize the risk of damage during transportation.

- Preventing Pollution: Extended exposure of empty plastic bottles to the air may lead to pollution. Manufacturing bottles on-site reduces the time they spend in an exposed state.

- Ensuring Sterility: The plastic bottle-making process involves heating preforms to high temperatures, ensuring the final product is sterile. This quick transition from production to bottling helps maintain a hygienic environment.

- Brand Protection: Famous bottled water companies often have unique and distinct bottle designs. In-house production safeguards the integrity of their brand by maintaining control over the manufacturing process.

- Cost Efficiency in the Long Run: While there may be initial setup costs, producing bottles in-house can be cost-effective over time. It provides greater control over production processes and minimizes dependency on external suppliers, potentially resulting in cost savings.

Application Areas

Cool tea bottle

PET provides a clear and transparent appearance, allowing consumers to see the product inside, which is appealing for beverages like cool tea.

Juice bottle

PET bottles have good resistance to impact and shattering, ensuring the safety of the beverage during handling and transportation.

Shampoos Bottle

PET bottles are lightweight, making them easy to handle and transport. This is beneficial for both manufacturers and consumers.

Makeup bottle

PET plastic provides excellent clarity, allowing consumers to see the color and texture of the makeup product inside the bottle. This transparency is advantageous for showcasing the product.

Medicines Bottle

PET bottles are durable and resistant to breakage, providing protection for pharmaceutical products during handling, transportation, and storage.

Icetea Bottle

PET is a recyclable material, aligning with environmental sustainability goals. Many recycling facilities accept PET bottles, contributing to the circular economy.

What Is the Materials ?

pET-preform

Conclusion:The use of preforms in plastic bottle production offers a practical solution for companies looking to streamline the manufacturing process. By leveraging the advantages of preforms, businesses can achieve.

Overview of Preforms

1. Preform Definition:A preform refers to the initial form or shape of a plastic bottle before it undergoes the process of blow molding. It is produced through injection molding, where molten plastic is injected into a mold to create a small, strong, and compact form.

2. Production Process:Preforms are manufactured using injection molding machines, which are specialized equipment for creating intricate plastic shapes. Injection molding involves injecting molten plastic into a mold cavity, where it solidifies into the desired shape.

3. Cost and Complexity: Injection molding machines are relatively expensive, and the production process requires technical expertise. Due to the complexity and cost, many bottled water companies choose to purchase preforms from specialized injection molding facilities.

4. Packaging and Transportation:Preforms are compact and durable, allowing for efficient packaging. Typically, a box can contain 500 preforms, and large quantities can be transported in containers, making them suitable for shipping and storage.

5. Advantages of Using Preforms:

- Cost-Effectiveness: Buying preforms can be more cost-effective for companies that don’t have the resources or expertise for in-house injection molding.

- Efficient Packaging: The small size and strength of preforms facilitate efficient packaging, reducing storage space requirements.

- Reduced Freight Costs: As preforms are compact and lightweight, they incur lower freight costs compared to transporting finished plastic bottles.

6. Challenges in Freight of Plastic Bottles:Weight and Volume: Plastic bottles, being lightweight and voluminous, can lead to higher freight costs. Additionally, the susceptibility to damage during transportation poses a challenge.

What is the Capacity of the water bottle manufacturing machine ?

4000 bottles per hour : depend on 200ml to 500ml bottle

3300 bottles per hour : depend on 600ml to 1300ml bottle

2500 bottles per hour : depend on 1500ml to 2000ml bottle

Can the plastic bottle maker handle different bottle sizes and shapes?

The bottle making machine is designed to support different bottle sizes and shapes. It offers flexibility in production, allowing for the manufacturing of bottles with varying volumes and designs. This adaptability is crucial for meeting the diverse demands of the market and catering to different product packaging requirements. Whether you need bottles for beverages, cosmetics, or other applications, the machine can be adjusted to produce a wide range of bottle sizes and shapes, providing versatility in your production capabilities.

Is the operation fully automatic, or does it require manual intervention?

Automatic bottle manufacturing machine operates fully automatically. Once the necessary parameters are set, the machine can perform the entire bottle manufacturing process, including heating, molding, and cooling, without manual intervention. This level of automation enhances efficiency, reduces labor requirements, and ensures consistent and high-quality bottle production.

Working process of CM-A4 pet bottle making machine

CM-A4 Automatic pet bottle making machine involving preform loading and subsequent bottle blowing, is a common method for efficiently manufacturing plastic bottles with consistent quality. It combines the advantages of preform flexibility and the ability to produce a variety of bottle shapes using dedicated blow molds

The process of making plastic bottles involves several key steps:

- Preform Loading:

- Workers manually load boxes of preforms into the preform loading machine.

- An automatic preform loader then takes over, conveying the preforms into the heating system.

- Heating System:

- The heating system utilizes infrared lamps to heat the preforms to the ideal temperature.

- The preforms, made of a hollow hard tube known as PET preform (produced by an injection molding machine), are prepared for the next step.

- Blowing System:

- The preheated preforms move into the blowing system.

- The blowing system, equipped with blow molds specific to each bottle design, shapes the preforms into the desired plastic bottles.

- This step is crucial for determining the final shape and characteristics of the bottle.

- Conveyor System:

- After the blowing process, the formed plastic bottles are conveyed by a conveyor system.

- The bottles are transferred out of the machine for further processing or packaging.

Working Proess

- 1. Preforms unscrambler will automatic load the preform.

- 2. Machinery gear will transfers the preform to the heating oven

- 3. 10psc infrared lamps can be adjusted individually to control the temperature of oven. Preform automatically rotate can make sure preform heating evenly. The infrared thermometer inspecting temperature and will automatic adjust it by itself. All parameter can saw in the touch screen of the Neptune automatic blow molding machine and can easy setting. So that can always fit the best heating temperature

- 4. The temperature sensor can inspectst the temperature of the preforms. According compare with preset data, it will automatic feedback data to oven, and Oven will automatic adjust the temperature to the necessary temperature.

- 5. Preforms star-wheel will automatic transfer the after heated preform to the blow mold.

- 6. First, the preform will stretched in the mold. And then will blow into shape plastic bottle by high pressure air.

- 7. Machinery gear will transfers the plastic bottle to the air conveyor belt.

- 8. Air conveyor belt will directly send plastic bottle to washing filling capping machine.

Video

Is the machine fully automatic or semi-automatic?

The machine is fully automatic. It operates seamlessly with high automation, reducing the need for manual intervention. In a fully automatic bottle making machine, the entire production process, including material feeding, heating, molding, and bottle ejection, is carried out automatically. This level of automation enhances efficiency, reduces labor requirements, and ensures consistent and reliable production. The machine is equipped with advanced control systems, allowing it to perform multiple tasks without the need for constant manual supervision.

What is the energy consumption of the bottle making machine?

The bottle making machine has a main machine with a rated power of 49 kW, but in actual operation, it uses around 10 kW. Additionally, the high-pressure (HP) air compressor consumes 25 kW, and the low-pressure (LP) compressor consumes 15 kW. It’s essential to consider both the main machine’s power consumption and the power requirements of auxiliary components, such as air compressors, to assess the overall energy consumption of the bottle making process.

bottle making Machine structure

It’s interesting to note that the Chief Engineer is a major shareholder in the company, which may indicate a strong commitment to quality and expertise in the field. Additionally, the combination of high-quality machines and competitive pricing suggests a focus on providing value to customers. Having a key figure like the Chief Engineer as a major shareholder could imply a hands-on approach to ensuring the excellence of the machines manufactured by the company.

Expertise and experience

Neptune machinery has a team of highly skilled and experienced engineers who have a deep understanding of blow molding technology and the needs of customers in blow mold machine industry. We design and build machines that are reliable and meet the exacting requirements of their customers.

Refine on Quality materials and components

Neptune machinery uses high-quality materials and components in the construction of the blow molding machines, which helps to ensure that the machines are durable and able to withstand the rigors of the manufacturing process.

Less than 0.1% damage bottle

Neptune machinery pays close attention to every detail of their blow molding machines, from the design and construction to the final assembly and testing. This helps to ensure that the blowing machines are of the highest quality and meet the needs of customers.

Change mold to produce different bottle on one machine

You can easy change blow mold to produce different shape and volume plastic bottle on one machine with 1hour change mold time.

Main parameter

Why need two step making water bottle?

Most strong thickness plastic bottle or container is directly injection or molding by one step making bottle technology. But one step is difficult to produce thin thickness plastic bottle. A lot kind of liquid need use thin thickness plastic bottle to container.

So that have two step making plastic bottle. The first step is injection a hard hollow preform. The second step is made use air blowing the preform into idea plastic bottle according the mold. The preform will been heating well before blowing.

- Low than 0.1% damage bottle compare with traditional blowing machine.

- PLC controlled, which ensures accurate and reliable operation.

- Individualized operations and operation monitoring of the machine are realized by human-machine interface.

- Moving parts are connected with boundary lubricating bearings and straight guide rails( guiding blocks are made in Japan)

- Use Japanese-bumper is adopted for preventing mechanical bumping, which ensures low mechanical noise, low failure rate and long service life.

- Unique design of air blowing mechanism ensures very high output rate of finished products

| Capacity of production | 4000 PCS/H |

| Bottle diameter | 20mm-100mm |

| Bottle Height | 50mm-350mm |

| Neck diameter | 15mm-38mm |

| Mold Cavity | 4cavities |

| Mold thick | 240mm |

| Volume of the bottle | 100ml-2000ml |

| Voltage | Can be setting |

| Rated Power | 49kw |

| Really use power | 10kw |

| LP air compressor | 2.0m3/min 1.0MPa |

| HP air compressor | 2.4m3/min 3.0MPa |

| Air dryer | 2.0m3/min 3.0MPa 1set |

| Cooling water | 15L/min |

| Main blower L*W*H | 1908*1858*1920mm |

| Main blower Weight | 3600kg |

| Preform unscrambler L*W*H | 276*106*186mm |

| Preform unscrambler Weight | 250kg |

| Metrials | PET preform |

Professional design and got high quality bottle

Professional design beauty bottle

NEPTUNE Machinery boasts a team of expert engineers dedicated to drawing and designing high-quality plastic PET bottles. With professionalism and extensive experience, they ensure that every design mark and line is flawlessly replicated in the actual PET plastic bottle during production. The structural integrity of the bottle is carefully considered to prevent any mishaps, ensuring that it stays securely in place on the conveyor belt throughout the water production process and remains stable when placed in shop freezers. This commitment to precision and reliability in design contributes to the overall excellence of NEPTUNE’s plastic bottle production.

Got High quality Plastic Bottle

A visually appealing plastic bottle has the power to capture consumer attention on supermarket shelves. The attractive design prompts people to reach out, inspect closely, and may even lead to increased purchases. Despite the affordability of bottled water, the visual appeal adds a touch of allure that encourages consumers to make a purchase, emphasizing the significance of an eye-catching design in the competitive market.

Bottle design

A well-designed bottle is crucial for the success of a bottled water company. Neptune utilizes professional bottle design machinery and expertise to ensure the final product matches the intended design precisely. This commitment to accuracy and quality results in bottles with clear markings that stand stably on the production conveyor.

The structural integrity of the bottle not only ensures stability during production but also enhances its appearance on store shelves. A good bottle design contributes to the overall success of the bottled water business by facilitating smooth production processes, conveying a professional image, and attracting consumers in retail environments.