WHAT IS THIS REVERSE OSMOSIS PLANT COST :

FOB PRICE $ 3480

What this price included?

- Filter tank stainless steel

- Pipe stainless steel

- RO membrane (4psc 4040)

- 2000LPH Quartz sand filter

- 2000LPH Active carbon filter

- 2000LPH Precision filter

- 2TON Water pump

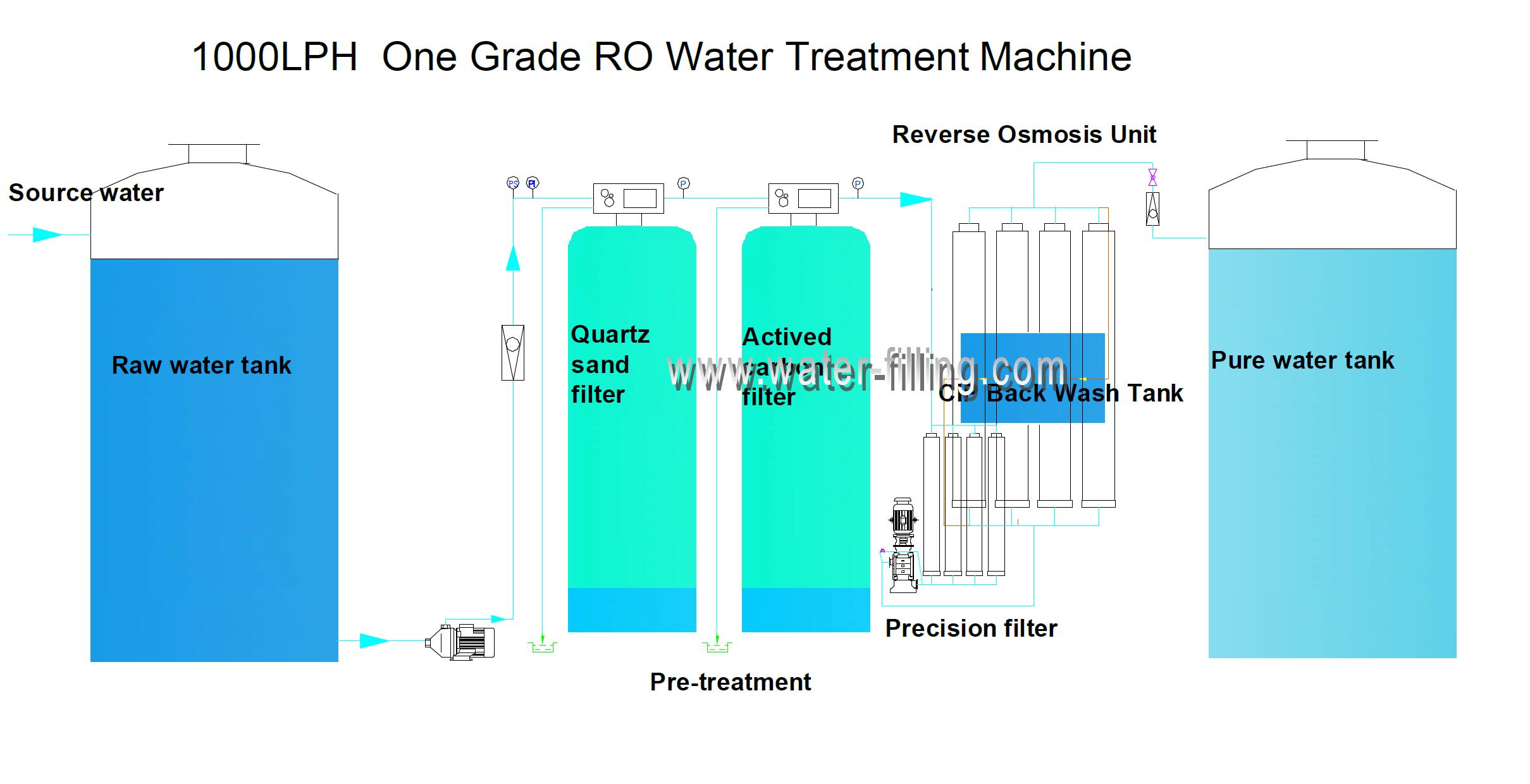

1000LPH Reverse osmosis water treatment plant with a production capacity of 1000 liters per hour is a robust solution for producing pure drinking water. Its ability to run continuously for 23.5 hours before a brief backwash period makes it efficient and convenient for water treatment applications. Here’s a breakdown of its key features:

- Capacity: The ro water plant has a production capacity of 1000 liters per hour, making it suitable for various applications, including meeting the demand for pure drinking water in commercial or industrial settings.

- Reverse Osmosis Technology: The use of reverse osmosis technology ensures effective water purification by removing a wide range of contaminants, including bacteria, viruses, heavy metals, and dissolved solids.

- Membrane System: The commercial ro plant 1000 lph comprises a semi-permeable membrane, a crucial component in the reverse osmosis process. This membrane allows only pure water molecules to pass through, blocking impurities and contaminants.

- Pre-treatment System: The pre-treatment system is responsible for removing larger particles and contaminants from the water before it enters the RO system. This step helps prolong the life of the RO membrane and enhances overall system efficiency.

- Pump: A pump is incorporated to force water through the RO membrane. This pressure-driven process is essential for separating contaminants and producing purified water.

- Post-treatment System: Depending on the specific characteristics of the raw water source, a post-treatment system may be included. This system can add minerals or other substances back into the water, improving taste and restoring pH balance.

- Backwash Capability: The ro water plant allows for a half-hour backwash period, which helps maintain the efficiency of the system by cleaning the RO membrane and preventing clogging or fouling.

- All-in-One Design: The all-in-one design streamlines the water treatment process, making it a comprehensive and user-friendly solution. This can be particularly beneficial for users who want a hassle-free and compact system.

Overall, the reverse osmosis water for plants appears to be a versatile and efficient solution for producing high-quality, pure drinking water in various settings. It combines key components and features to ensure reliable performance and ease of operation. Help you setup a water factory reverse osmosis system.

| Capacity purified water | 1000 Liter per hour |

| Cost raw water | 1300 Liter per hour |

| RO membrane | 4 psc 4040 |

| Quartz sand filter | Flow: 2 ton per hour Media: 100 kg carbon |

| Active carbon filter | Flow : 2 ton per hour Media: 50 kg of quartz sand |

| Precision filter | Three set PP filter PP30-40 Flow 2M3 |

Technique Process of the 1000LPH reverse osmosis plant

Raw water quality and the design of the system. However, the general steps you’ve outlined provide a comprehensive overview of the typical process involved in a reverse osmosis plant. Here are a few additional details and considerations:

- Monitoring and Control: Many advanced RO systems include sensors and control systems to monitor water quality and adjust parameters such as pressure and flow rates in real-time, ensuring optimal performance.

- Backwashing: While not explicitly mentioned in the process, it’s common for RO systems to undergo periodic backwashing. This is a crucial step to clean the membrane and prevent fouling, extending the lifespan and efficiency of the system.

- Anti-scalant Injection: In cases where the raw water source has a high mineral content, anti-scalant chemicals may be injected into the system to prevent the buildup of scale on the membrane, which can reduce efficiency.

- Automatic Flushing: Some systems incorporate automatic flushing mechanisms to clean the membrane surface and prevent the accumulation of impurities.

- Water Quality Testing: Regular testing of the purified water is essential to ensure that it meets the desired quality standards. This may involve checking parameters such as TDS (Total Dissolved Solids), pH, and microbial content.

- Regulation Compliance: Depending on the application, the water treatment process may need to comply with regulatory standards and guidelines set by local authorities or industry-specific bodies.

- User Interface: Modern RO systems often feature user-friendly interfaces for monitoring and controlling the system. This may include digital displays, alarms, and remote monitoring capabilities.

- Waste Management: Proper disposal or treatment of the concentrate stream containing removed contaminants is a critical consideration to minimize environmental impact.

By addressing these aspects, a 1000LPH RO water treatment machine can provide a reliable and efficient solution for producing high-quality purified water across various applications.

How does reverse osmosis technology work in the water purification process?

Quartz Sand Filter, 1th Prepare Filter For RO Device

In order to protect the back-end filters, we adopt the quartz sand filter .

Quartz sand filter (Optional manganese sand)Removed big suspendid of raw water. Remove different types of particles, such as suspended solids (turbidity), colloidal compounds and etc.

Quartz sand filter will reduce the load on the back-end filters Water production index: SDI<1-3.

After a period of time, the filter will be saturated. In order to restore its function, the filter needs backwashes. In order to achieve its best results, the efficient backwash needs taking 20-30min. This filter is fitted with two diffusers, a manhole for discharge media.

Activated Carbon Filter, 2th Prepare Filter For RO Device

In order to protect the back-end filters, we adopt the active carbon filter .

Active carbon filter remove of organic substance and heavy metal element, suspended solids and etc. It can effectively reduce the level of COD and improve the taste of water.

With a valve operating system, pipeline system, containing the manhole, hand hole, the upper and lower water distribution devices, media, pressure.

After a period of time, the media will be saturated and it needs backwashes. In order to achieve its best results, the efficient backwash needs taking 20-30min. This filter is fitted with two diffusers, a manhole for load media

Precision Filters, 3th Prepare Filter For RO Device

Prevent the particles entering the membrane, scratched the surface of the membrane. In the normal operating condition, the filter can maintained for 3 mouth. The filter structure for fast replace.

Manufacture of high quality PVC material. Filter holder containing a fixed The 5μm PP filter is most commonly used for dealing the pure water. It is generally believed that the harmful particles and bacteria are larger than 0.22μm.

In order to prolong the life of RO membrane, the whole system adopts one set of stainless pp filter. The polypropylene microporous filter cartridges with the length of 40 inch in 5μm filters respectively. The 5μm filter acts as the protector of the RO membrane, filtering the vast majority of particles in the water, which eases the load of RO membrane and prolong its life.

The filter cartridges are for one-time use, as the particles retained in the gap of microporous filtering film is hardly removed by rinsing with acid-base. After a period of time, the filter cartridge needs to be replaced. The structure of them makes replacement of cartridge convenient. This apparatus contain filtration cartridges and stainless support layers. The support layer is made of stainless steel 304, with the advantages of compact structure, beautiful shape, high flux, good filtration accuracy and etc.

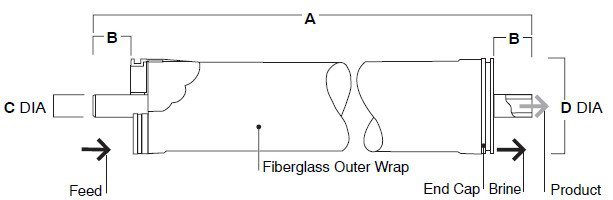

RO membrane

comprehensive overview of the operation, features, and maintenance aspects of a Reverse Osmosis (RO) water treatment system. Here’s a summary of the key points:

- RO Membrane Washing:

- The RO system includes both automatic and manual washing capabilities for the RO membranes.

- Manual washing with a specific medicine is mentioned, indicating a targeted approach to membrane cleaning.

- Automatic Control Features:

- Automatic control features include high water level auto-stop and low water level auto-start functions, ensuring efficient operation and water level management.

- Pump Protection:

- The system has protective measures for the multi-phase pump to prevent damage in the absence of water.

- Power-related Protections:

- The RO system is equipped with safeguards for power-related issues, including protection against power loss, poor power quality, over electrical current, short circuits, and circuit breaker issues.

- Leakage protection is also mentioned, emphasizing safety measures.

- RO Membrane Function:

- The RO membranes effectively remove hydronium, organic substances, colloids, bacteria, and other impurities through the process of reverse osmosis.

- Desalination and purification are highlighted as the primary functions of the RO system.

- Reverse Osmosis Process:

- The theory of reverse osmosis involves separating treated and untreated water with a semi-permeable membrane.

- Osmotic pressure and applied pressure drive the osmosis process, resulting in purified water while solutes and suspended substances are drained as waste water.

- Pretreatment Requirement:

- Emphasis is placed on the necessity of pretreating water before entering the RO system to prevent damage to the RO membrane.

- Additional Filtration Capability:

- The RO system is versatile, not only for desalination but also for filtering organic substances and bacteria.

- Monitoring and Maintenance:

- Production of water is monitored using a liquid crystal display conductivity meter.

- Regular cleaning of various components, including the stainless steel pump, filter, disinfectant tank, and valves, is crucial for system maintenance.

- Operational Schedule:

- The system is recommended to work at least once every day, with protective measures required if it remains inactive for an extended period to preserve the membrane’s service life.

- RO Membrane Type and Longevity:

- The system uses low-pressure, large-flux 4040 RO membranes, and proper maintenance can ensure their service for years.

Your explanation provides valuable insights into the functioning and care of the RO water treatment system, making it clear that regular maintenance and proper operation are essential for its optimal performance and longevity.