FOB PRICE $ 89490

What This Price Included ?

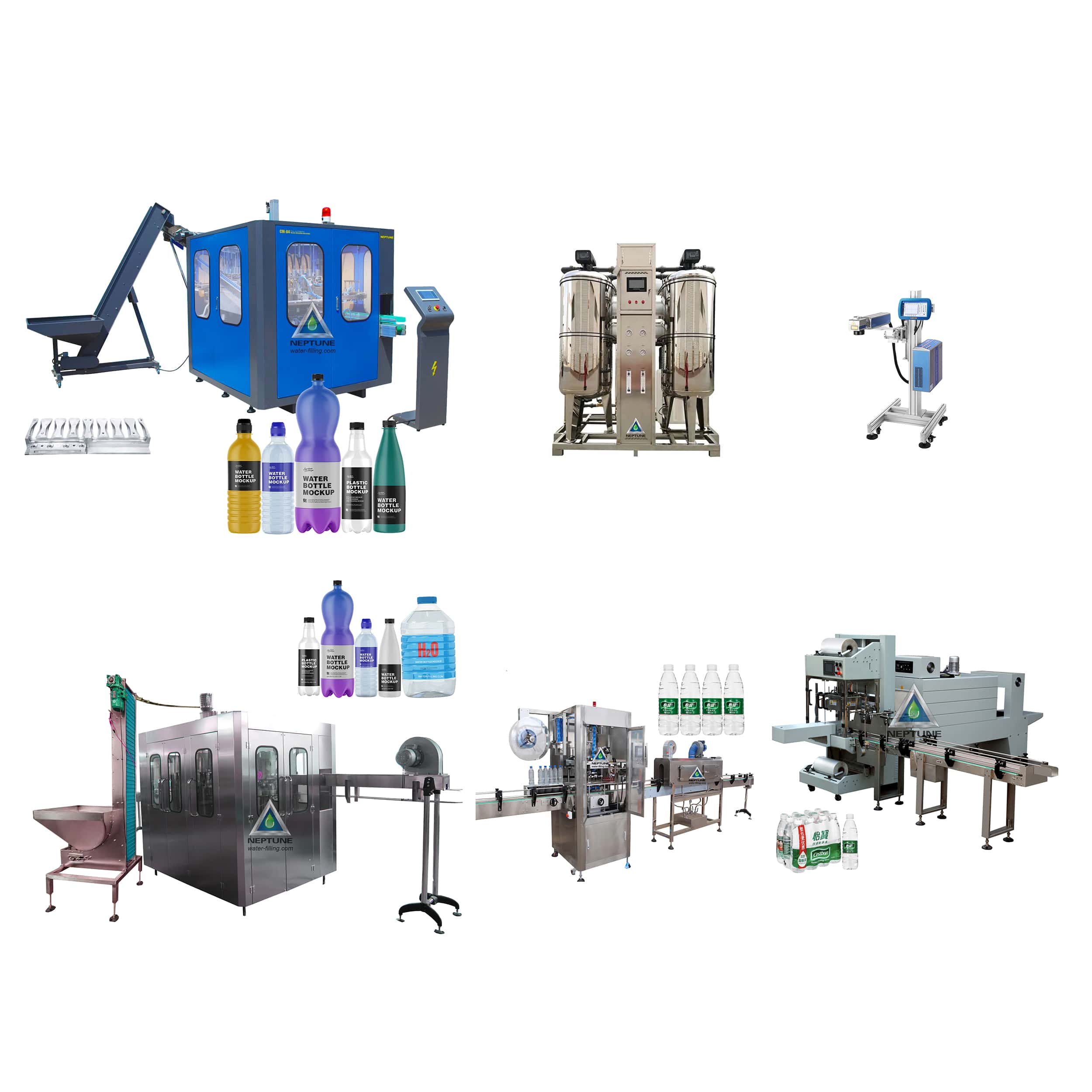

- BM-A4 AUTOMATIC BLOW MOLDING MACHINE; 1 full set

- 3000L/H RO WATER TREARMENT MACHINE; 1 full set

- NF 16-12-6 BOTTLE WASHING-FILLING-CAPPING MACHINE; 1 full set

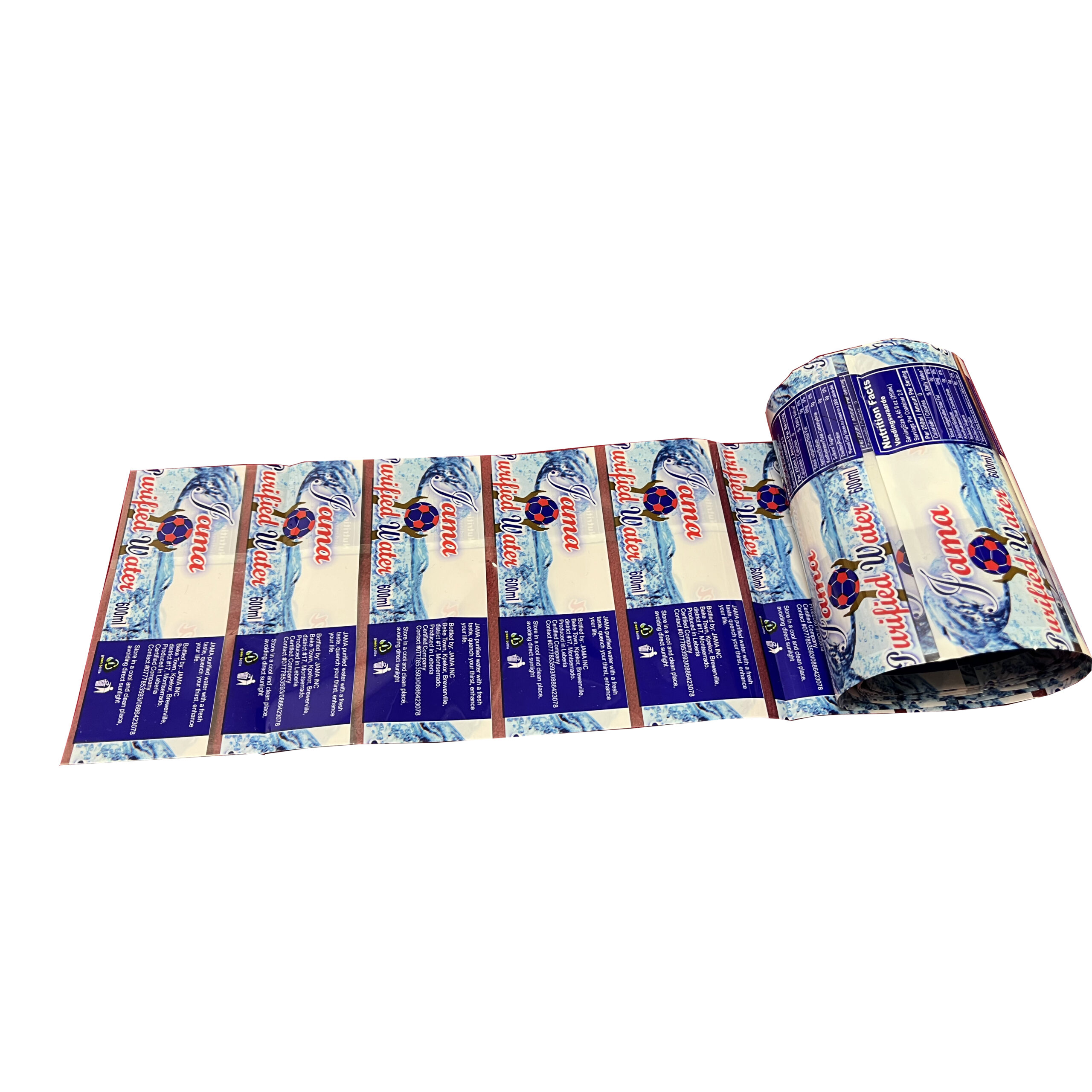

- HP-250 AUTOMATIC SLEEVE LABELING MACHINE;1 full set

- LASER PRINTER;1 full set

- AUTOMATIC THERMO SHRINKAGE PACKAGE MACHINE;1 full set

Imagine a water bottling process where everything happens seamlessly, all under one roof! Introducing our state-of-the-art 6-in-1 bottle water production machine, combining innovation and efficiency like never before.

Key Features:

- ✅ Bottle Making: Craft your own bottles with precision and flexibility.

- ✅ Water Purification: Ensure the highest quality water for your bottled products.

- ✅ Laser Date Printer: Mark each bottle with precision and traceability.

- ✅ Washing, Filling, Capping: From cleanliness to sealing, every step is flawlessly executed.

- ✅ Labeling: Add the finishing touch with accurate and eye-catching labeling.

- ✅ Packaging: Streamline your production with a built-in packaging system.

Why Choose Our 6-in-1 Bottling Machine Plant?

🔄 All-In-One Efficiency: No need for multiple machines – it’s a complete solution.

🌐 Space-Saving Design: Maximize your floor space with integrated functionalities.

🌟 Optimized Workflow: Minimize manual handling for a smoother production line.

💡 Innovation at its Core: Stay ahead in the bottled water industry with cutting-edge technology.

Ready to elevate your bottled water business? Click the link for more details and take the first step toward a revolutionized production process!

What is the production capacity of the 6IN1 water bottling machine Plant ?

- 500ml Bottles: 4,000 bottles per hour (Can running 24hours per day )

- 1500ml Bottles: 2,000 bottles per hour (Can running 24hours per day )

- 1000ml Bottles: 3,000 bottles per hour (Can running 24hours per day )

- 350ml Bottles: 4,000 bottles per hour (Can running 24hours per day )

Does the machine support different bottle sizes?

🌐 Versatility at Its Best! Our Bottling Machine Supports Various Bottle Sizes. 🔄💧

With our advanced water bottling machine, you gain the power of versatility. It can seamlessly produce bottles in a spectrum of volumes and shapes, including but not limited to:

- 200ml, 300ml, 333ml, 350ml, 450ml, 500ml, 555ml, 600ml, 700ml, 800ml, 900ml, 1000ml, 1200ml, 1500ml, 1800ml, 2000ml

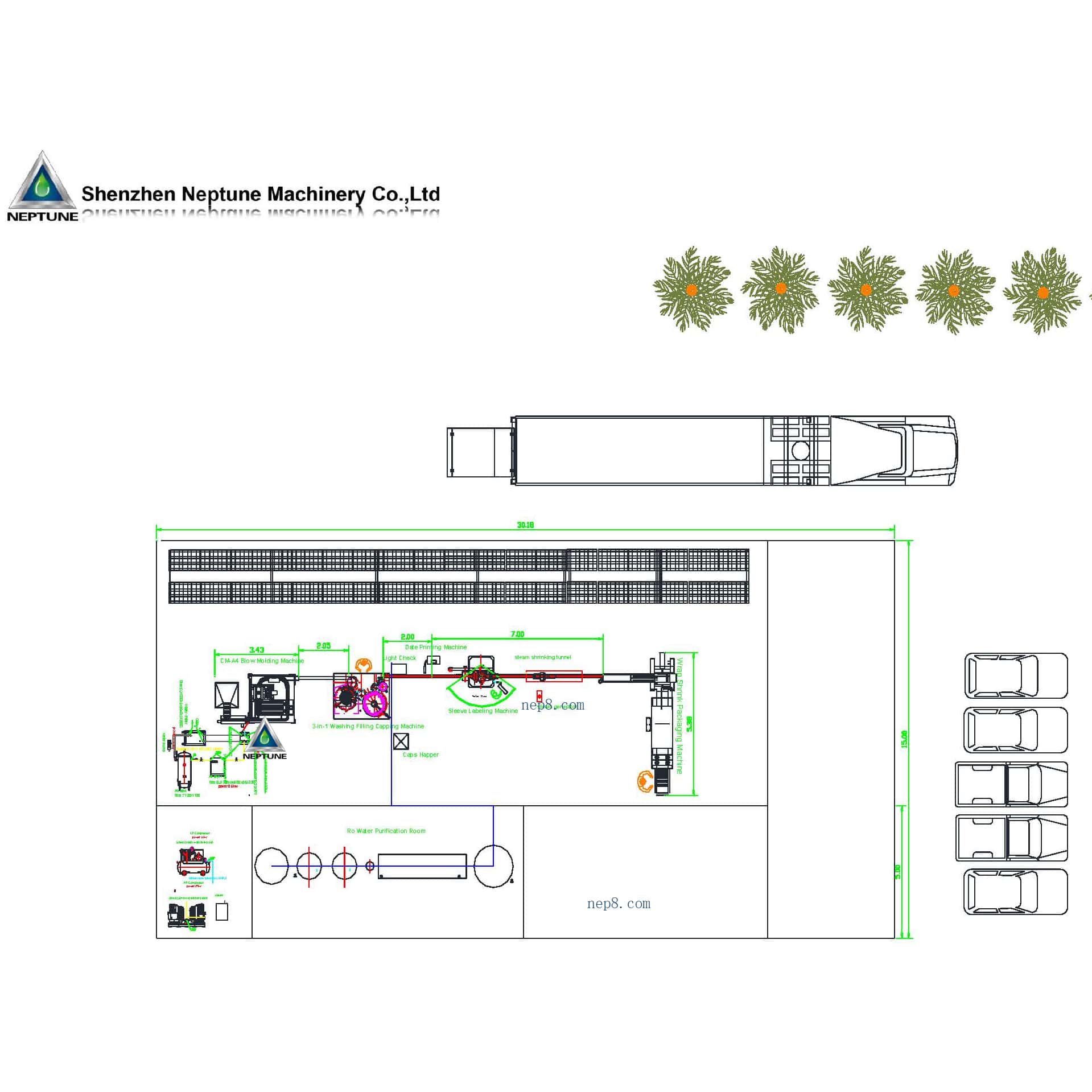

What is the overall footprint and space requirements for the machine?

🏭 Optimizing Space for Efficiency! Our Bottling Machine’s Footprint: 🌐📏

- Minimum Space: 10 meters width x 20 meters long production room.

- Ideal Space: 15 meters width x 30 meters long production room.

Why Our Bottling Machine Fits Your Space:

- 🌟 Efficient Layout: Designed for streamlined production in compact spaces.

- 🚚 Truck Accessibility: Ideal for the first floor, ensuring easy truck entry for efficient product freight.

🚢 Smooth Shipping Process! Our Machines Require Two 40HQ Containers for Shipment. 🌐📦

Shipment Details:

- Container Type: 40HQ (High Cube) Containers

- Quantity: 2 Containers

Why Opt for Our Shipment Solution:

- 🌍 Global Reach: Ready for shipment to destinations worldwide.

- 🔄 Secure Transit: Ensuring the safe transportation of your valuable equipment.

🤖 Effortless Automation! Our Water Bottling Machine Plant is Fully Automatic and Synchronized. 🔄🏭

Key Features:

- Automation Level: Fully automatic for a hassle-free production process.

- Synchronization: Every machine is seamlessly connected through a conveyor belt.

Why Opt for Full Automation: 🚀 Optimal Efficiency: Maximize productivity with minimal manual intervention. 🔄 Synchronized Workflow: Ensure a smooth and continuous production line. 🌐 Cutting-Edge Technology: Embrace the future with advanced automated solutions.

🔧 Comprehensive Support! Our Bottling Machine Comes with Installation and Training Services. 🌐🛠️

Service Offerings:

- Installation: Comprehensive installation support included.

- Oversea Installation: Option to send an engineer for seamless setup.

- Worker Training: Engineer-led training sessions for your production team.

Why Choose Our Installation Services: 🚀 Seamless Setup: Ensure a smooth start with our expert installation. 🔍 Global Support: Access to overseas installation for your convenience. 👩🔧 Skilled Workforce: Equip your team with hands-on training from our experienced engineer.

🛡️ Peace of Mind Guaranteed! Our Bottling Machine Comes with a 1-Year Warranty and Lifelong After-Sales Support. 🌐🔧

Warranty and Support:

- Warranty Period: 1 year for added peace of mind.

- Lifelong After-Sales: Continuous support throughout the machine’s lifespan.

- Proven Track Record: Customers still rely on us for spare parts after 15 years.

Why Trust Our Warranty and After-Sales: 🔒 Security: A solid 1-year warranty to safeguard your investment. 🔄 Long-Term Commitment: Lifelong support, proven by our customers’ trust over 15 years. 🔧 Accessible Spare Parts: Ensure seamless operation with readily available spare parts.

What materials are used in the construction of the machine?

- Preform: High-quality material for crafting durable plastic bottles.

Water Cap: Ensures a secure seal for every bottled water product.

PVC Label: Used for precise and eye-catching sleeve labeling.

Wrap Film: Packaging solution for bundling 12/20/24 bottles in one bag.