The Juice and Tea Hot Filling Line is a sophisticated and efficient system designed for the hot filling and bottling of beverages such as green tea, black tea, and juice. With a scientifically and reasonably crafted design, this production line not only boasts a visually appealing appearance but also ensures seamless operation and convenient maintenance. Its high level of automation makes it an excellent choice for hot filling drinks.

Key Features:

- Scientific and Reasonable Design:

- The production line features a well-thought-out design, ensuring the scientific and efficient hot filling of beverages.

- Aesthetic Appeal:

- The equipment is designed with an aesthetically pleasing appearance, contributing to a visually appealing production environment.

- Convenience in Operation and Maintenance:

- The system is user-friendly, providing easy operation and maintenance procedures for efficient workflow.

- Highly Automatic:

- Boasting a high level of automation, the hot filling line minimizes manual intervention, ensuring precision and consistency in the filling process.

- Versatility:

- The line is versatile, accommodating various types of beverages, including green tea, black tea, and juice, making it adaptable to different production needs.

- Good Equipment for Hot Filling:

- Specifically designed for hot filling applications, the production line ensures the preservation of beverage quality and flavor during the filling process.

- Efficiency in Production:

- The system is optimized for efficient production, streamlining the hot filling and bottling process to meet industry demands.

- Automation for Consistency:

- Automated processes contribute to the consistency of product quality, reducing the likelihood of errors during production.

- Comprehensive Solution:

- The Juice and Tea Hot Filling Line provides a comprehensive solution for businesses involved in the hot filling of beverages, offering reliability and performance.

- Adherence to Quality Standards:

- Designed with a focus on quality, the hot filling line ensures that beverages meet the required standards, maintaining product integrity.

This equipment is an ideal choice for businesses seeking a reliable and efficient solution for the hot filling and bottling of various beverages. Its combination of scientific design, aesthetic appeal, and automation makes it a valuable asset for the production of high-quality drinks in a hot filling process.

What is Juice and Tea Drink Hot Filling Line

Juice and tea hot filling line is used in hot filling and bottling for green tea, black tea and juice. The design is scientific and reasonable with good-looking appearance. Its operation and maintenance is convenient and is highly automatic.It is a good equipment for hot filling drink.

What is different between juice and water bottling line?

Aseptic sterilization

(temperature control)

Pure water without anything and not easy for pollution by bacteria in the air. But juice have syrup and Nutrients. If a bacteria will pollution an bottle juice. Even the cap or bottle touch air will been pollution by air.

So that the juice hot filling line key is spuer high temperature Instantaneous sterilizer. It increase juice temperature to 135degree. And more important is other machine keep the juice tempeture at 80-90degree and filler into bottle and cap well. Then turn the bottle 360 angle. To let the juice touch inside of the cap. So that juice with high tempeture can also kill bacteria inside of the bottle.

Syrup

Because juice have syrup. If closed machine long time syrup will stack the pipe. So that every time close the juice line need use hot water washing the inside of the pipe. And every time running the juice line also need use hot water washing the inside of the pipe. It need fit an CIP back washing system

Why choice hot-filling juice ?

There are two kind of juice filling in the world. Aseptic cold filling and hot filling.

Aseptic cool filling machine and factory are kept sterile, so it is not necessary to add preservatives to the beverages, and it is not necessary to perform post-sterilization after filling and sealing the beverages. Long shelf life requirements while maintaining the taste and color of the beverage. But its whole production line price total over 2millions dollar and factory need very high standard.

Hot filling: Juice is mixer in an process of sterile environment beverage equipment. Whole process is inside stainless steel tank and pipe. Its key is made use UHT high temperature instantaneous sterilization. Then cooled the juice to 90 degrees and filler the juice into the plastic bottle. The juice plastic bottle is specially materials and production process. It can standard the 90 degrees temperature.

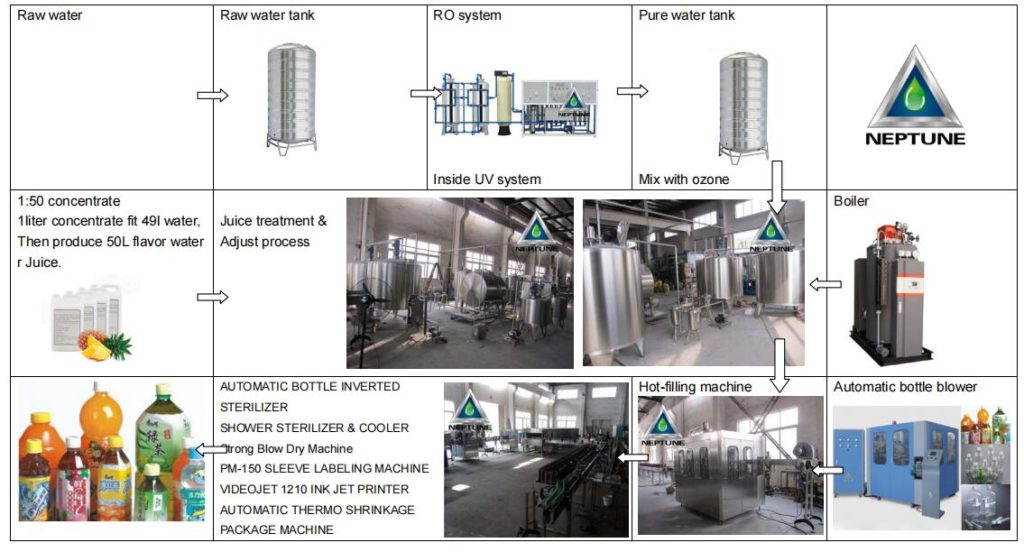

How do hot-filling bottled juice line work?

Our concentrate juice& tea production line included the water treatment unit, blow molding machine, air conveying system, tea/fruit juice/vegetable juice preparation system (homogenizer, degasser, ultra high temperature sterilizer, CIP machine, three-in-one hot filling system, sterilizing machine, Tunnel pasteurizer, auto conveying system, air purification system, OPP/PVC labeling machine, wrap shrink packing machine, and more).

HOT FILLING AUTOMATIC BLOW MOLDING MACHINE

It seems you’re looking for comprehensive support in the manufacturing process, including the design of perform and bottle molds, assistance with machine installation, and specialized preform considerations for hot filling blow molding machines. Here’s an elaboration on your requirements:

1. Design of Perform and Bottle Molds:

- Customized Molds: We provide whole drawings for the perform and bottle molds tailored to your specifications.

- Word Design on Moulds: Enjoy complimentary word design on the molds to enhance brand visibility and product aesthetics.

2. Machine Installation Support:

- Comprehensive Assistance: Our team is dedicated to helping you throughout the machine installation process.

- Testing Services: We conduct thorough testing to ensure the machine is functioning optimally.

3. On-site Check and Maintenance:

- Quality Assurance: We offer on-site checks to guarantee the machine’s good working condition.

- Maintenance Services: Our support includes periodic maintenance to address any issues and ensure continued efficiency.

4. Cost Considerations:

- Installation Cost: While machine installation support is provided at no charge, a nominal fee covers flight charges and accommodation for our team during the installation process.

5. Hot Filling Blow Molding Machine Features:

- Simultaneous Heating and Blowing: The hot filling blow molding machine is designed to heat the mold concurrently with the preform blowing process.

- Specialized Preform for Juice: We offer specially designed preforms suitable for hot filling applications in the juice industry.

6. Additional Services:

- Word Design on Moulds: Our team provides free-of-charge word design on the molds to align with your branding strategy.

- Technical Expertise: Benefit from our technical expertise in ensuring the proper functioning of the entire system.

7. Collaborative Partnership:

- Customer-Centric Approach: We prioritize a customer-centric approach, ensuring your satisfaction and success in the production process.

- Tailored Solutions: Our services are tailored to meet your specific needs, offering a holistic solution for your bottling requirements.

8. Continuous Support:

- Ongoing Assistance: Beyond installation, we offer continuous support to address any operational concerns or optimizations needed.

Feel free to provide more details or specific requirements, and our team will ensure your needs are met throughout the entire process.

RO WATER TREARMENT SYSTEM

Reverse Osmosis System for Drinking Water:

- Water Supply:

- Source: Utilizes tap water as the primary water supply.

- Quartz Sand Filter:

- Purpose: Removes suspended particles, micelles, and other impurities from the water.

- Functionality: Acts as the initial step in purifying the water by filtering out larger contaminants.

- Active Carbon Filter:

- Purpose: Eliminates organic substances, chlorine, chromo, odors, and other impurities.

- Functionality: Enhances water quality by removing various chemicals and undesirable elements.

- Softener Filter:

- Purpose: Reduces water hardness caused by minerals like calcium and magnesium.

- Functionality: Ensures the water is appropriately conditioned for optimal performance in the RO system.

Pretreatment System:

- Function: The combination of the quartz sand filter, active carbon filter, and softener filter forms a consummate pretreatment system.

- Objective: Prepares the water for the subsequent stages in the RO process by removing specific impurities and adjusting its characteristics.

RO System:

- Objective: The pretreated water meets the requirements of the RO system, ensuring stable and efficient operation over an extended period.

- Functionality: Utilizes a semi-permeable membrane to separate contaminants, minerals, and impurities, producing high-quality drinking water.

Key Benefits:

- Enhanced Purity: The multi-stage pretreatment ensures the removal of various impurities, resulting in high-purity water.

- Long-Term Stability: The RO system’s stability is maintained by providing water that adheres to its specific requirements.

Operational Overview:

- Sequential Process: Tap water is sequentially processed through the quartz sand filter, active carbon filter, softener filter, and finally, the RO system.

- Water Quality Assurance: Each stage contributes to achieving water quality standards suitable for consumption.

Conclusion:

This RO system, coupled with the consummate pretreatment system, underscores a comprehensive approach to water purification. By removing diverse impurities, the system ensures the production of stable, high-quality drinking water.

Sugar melting pot

Sugar Melting Pot is made of 304 Stainless Steel. It can melt the sugar to syrup by warming the tubular electric heating pipe and homogenize the syrup by motor’s mixing. This machine has both inside and outside layers, on the middle is the high quality temperature keeping material. It is the ideal equipment to melt sugar to syrup. First add water into the Sugar Melting Pot, and the water level should be about 25% of the total volume.Then pour the sugar into the machine, turn on the power and it will start to warm. After about 1 hour warming, the sugar will start to melt, at this time turn on the power to homogenize the syrup by motor’s mixing.

Syrup filter

Syrup Filter is made of 304 Stainless Steel. Inside is the pure natural tianzi cotton. Filtering by tianzi cotton is very clean and the operation is convenient. So the Syrup Filter is the ideal equipment to filter the syrup.First connect the Syrup Filter with the High Temperature Pump and Sugar Melting Pot. Then open the water pump to make the syrup in the Sugar Melting Pot filtered by the tianzi cotton in the Syrup Filter, so that the inpurity can be got tod of.

Preparation Tank

Preparation Tank is made of 1Cr18Ni9Ti high quality Stainless Steel. It is composed of stack shell, cycloid pin gear reduction drive, mixing device to homogenize all the raw meterial with water. So it is an ideal equipment in drink, medicine industry, etc.

It should be sterilized by sterilizing liquid before using.(User should prepare the sterilizing liquid for themselves.) After sterilizing, wash the machine and clean out all the sterilizing liquid by filtered water.

Double Filter

Double filter use for filtering liquid

Contunous operation

Easy to replace filtering screen

High Pressure Homogenizer

The machine is the necessary key equipment for cold drink and milk drink,The pressure covers 250-60kg/M2,and the productivity covers 500-5000kg/m.The machine has filter unit to guarantee the machien operate normally.

Vacuum Dearating Machine

The deaerator is one of the necessary equipment in fruit juice or fruit tea production line.It is mainly used for deaerating the homogenized juice under vacuum condition and to prevent juice from being oxidized and then to proling the storing period of the juice.

Vertical Type Cooling & Heating Device

The device is widely used in milking and pharmaceutical industries,is necessary equiipment for heating,cooling,heat insulationg and steritizing the liquid material,It has the advantages of energy saving,noise eliminating,acid resistant,crack-proofmand easy cleaning and operating,It is also necessary equipment drink production line.

Ultra Temperature Instantaneous

Sterilizer Factory adopts advanced stainless welding techology from abroad,selecting the fine polished stainless steel tube.which had improved greatly comparing with the former productes we manufactured .There are two kinds of specification: manual control and automatic control,It is suitable for the liquid material,.such as fresh milk,fruit drink,wine,soybean milk and Chinese medicine,as well as the sticky material(For example.swear condensed milk) upon completing with high-pressure homogenizer.The information of other automatic UHT completing with aseptic packing machine is ready for you.

Vertical Type Cooling & Heating Device

The device is widely used in milking and pharmaceutical industries,is necessary equiipment for heating,cooling,heat insulationg and steritizing the liquid material,It has the advantages of energy saving,noise eliminating,acid resistant,crack-proofmand easy cleaning and operating,It is also necessary equipment drink production line.

CIP Cleaning In Place

The rinsing system is used not only to clean at site of material pipe of the industries like milk products, juice, beverage and recipients, but also to the beer and other food manufacturers.

A centrifugal pump is used in CIP to convey cleansing liquid into material pipe and equipment recipients to force the cleansing liquid to circulate to make cleaning without taking apart pipes or equipments. With the system the equipment availability can be improved and intensity of labor lessened. So the system is an advanced and ideal equipment of cleaning technology.

The detailed operation should be equipped and combined with the equipments in the plant, the layout of the pipes, the cleaning head, and so on.

Hot-filling washing filling capping machine

1.Entering and Exit Bottle Type: Straight line, that is bottle entering on the left side of the chain, bottle exit on the right side of the chain.

2.Rotational Direction of Each Machine: Clockwise;

3.Washing, Filling Pipeline: Liquid Supplying in the lower

Structural Design: The sanitary demands is thought completely in the unit.

1.The filling cylinder, filling valve and all of parts which touch the materials are all made of micro-carbon stainless steel. It has good corrosion-proof characteristics

and it is easily washed.

2.The work table is covered with stainless steel and strictly sealed to protect the driving device in the ground frame. It is helpful for washing table and keep clean.

Filling Quality: High-speed, high-quality filling valve ensure good filling quality.

1.Filling Valve used in RCGF Type Washing, Filling, Capping (Three-in-One) Unit has high filling efficiency. Its registered filling speed is 125ml/s, no filling loss, no

leak in exhausting pipe.

2.The liquid level in bottle controls correctly. Its height error is different with the bottle neck diameter. Normally, it does not surpass ±5mm.

3.Filling action is correct.

Capping Quality:

Capping adopts magnetic constant moment to screw cap. The screwing cap moment is adjustable steplessly to reduce cap damaging and the seal is tightly.

Operation is reliable. It adopts PLC programmable control and it has high automation level.

1.It adopts frequency controller to govern steplessly. The speed adjustment is very convenient.

2.It has safe and reliable auto filling system. No-Bottle no-opening valve safe device makes filled liquid no lose.

3.The liquid level of the floating ball is installed to control correctly the liquid height in the filling cylinder to make the filling valve work steadily.

4.It has auto-stop protection while bottle is blocked and start wheel displaces. Once a bottle is dropped and the driving wheel is blocked to make the star wheel

displaces, the machine will auto stops at once to avoid the machine damaging.

The run is steady: The design of the bottle chain and material ensure steady supplement of bottles. The start wheel and bottle guide plate are made of stainless

steel and engineering plastic product to ensure bottle steady moving at high speed.