FOB Price $ 11840

What this price included?

- Filter tank stainless steel

- Pipe stainless steel

- 5PSC Dow BW30-400FR

- 10000LPH Quartz sand filter

- 10000LPH Active carbon filter

- 10000LPH Precision filter

- 10TON Water pump

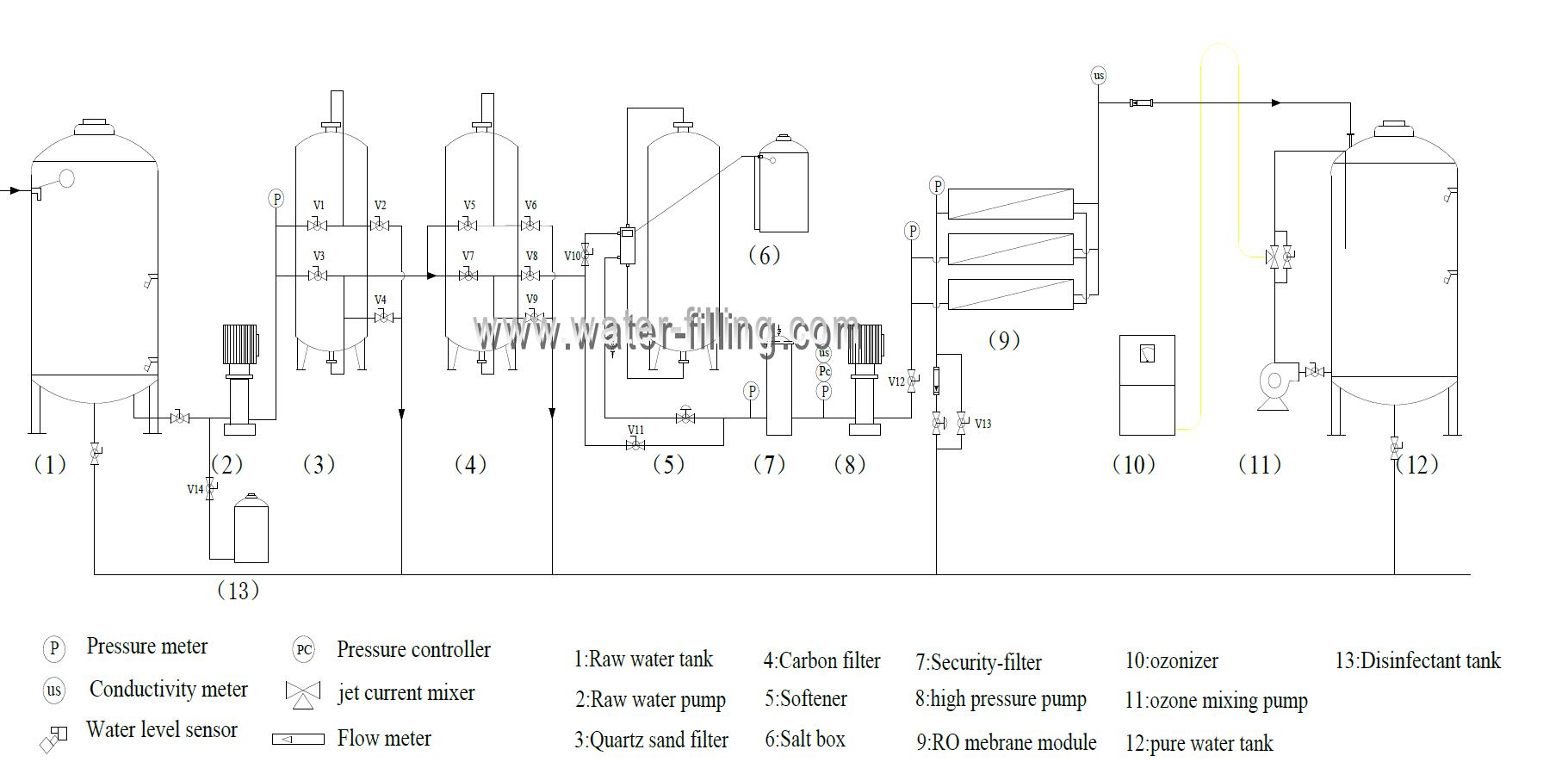

5000LPH RO Water Treatment Machine – a high-capacity system meticulously engineered to elevate water purity by eliminating impurities and contaminants. This advanced technology encompasses multiple stages of filtration and treatment, ensuring a comprehensive purification process.

Key Components:

- Sediment Filtration: The initial stage efficiently removes larger particles such as dirt, sand, and rust, setting the foundation for further purification.

- Activated Carbon Filtration: This stage targets smaller particles like chlorine, organic compounds, and odors through the process of adsorption, enhancing the overall quality of the water.

- Reverse Osmosis (RO) Filtration: The core of the system, RO filtration, employs high pressure to force water through a semi-permeable membrane. This step effectively eliminates even the smallest particles, including viruses and bacteria.

- Optional Water Softener: Recognizing the prevalence of water hardness issues, the machine offers an optional water softener stage. This component addresses the removal of excess minerals such as calcium and magnesium, mitigating problems like scale build-up in pipes and appliances, and soap scum formation.

Applications:

- Drinking and Cooking: Delivering water of exceptional quality, our 5000LPH RO Water Treatment Machine is ideal for providing purified water for drinking and cooking purposes.

- Industrial Use: With its substantial capacity, the machine is perfectly suited for high-demand industrial applications where a large volume of purified water is essential.

Benefits:

- Comprehensive Purification: The multi-stage process ensures a thorough removal of impurities, guaranteeing water purity across various applications.

- High Capacity: Designed to meet the demands of high-volume requirements, the 5000LPH capacity makes it a reliable solution for industrial and large-scale applications.

- Customizable: The optional water softener allows customization based on regional water quality, addressing specific concerns related to water hardness.

In conclusion, our 5000LPH RO Water Treatment Machine is a pinnacle of water purification technology, offering a robust solution for a myriad of applications. Trust Neptune Machinery to provide excellence in water treatment solutions, catering to the diverse needs of industries and communities alike. Elevate your water quality with our advanced and reliable technology.

| Capacity purified water | 5000 Liter per hour |

| Cost raw water | 6700 Liter per hour |

| Waste water | 1700 Liter per hour |

Process of 5000LPH RO water treatment machine

1. quartz Sand Filter

10000LPH (liters per hour) quartz sand filter is a type of filter used in a reverse osmosis (RO) system to remove impurities from water. The filter is typically made of a cylindrical tank filled with quartz sand, which acts as a physical filter to remove suspended solids and other contaminants from the water.

Quartz sand is a highly effective filter media because it is chemically inert and has a high surface area, which makes it efficient at trapping contaminants. The filter works by forcing the water to pass through the sand, where the contaminants are trapped and removed.

2. Active carbon filter

10000LPH (liters per hour) active carbon filter is a type of filter used in a reverse osmosis (RO) system to remove impurities from water. The filter is typically made of a cylindrical tank filled with activated carbon, which is a type of carbon that has been treated with oxygen to make it highly porous and effective at trapping contaminants.

The filter works by forcing the water to pass through the activated carbon, where the contaminants are trapped and removed. Activated carbon is effective at removing a wide range of contaminants, including organic compounds, chlorine, and other chemicals. It is often used in conjunction with other types of filters, such as quartz sand filters, to provide a multi-stage filtration process that removes a variety of contaminants from the water.

3. Precision Filter

10000LPH precision filter, also known as a fine filter or membrane filter, is a large-capacity filter that is commonly used in reverse osmosis (RO) systems to remove impurities from water. It is typically made from a thin, semi-permeable membrane that is effective at removing very small particles, such as bacteria, viruses, and other contaminants.

Precision filters are typically used as the final step in an RO system, after the water has been treated with other types of filters, such as sediment filters and activated carbon filters. They are effective at removing any remaining impurities from the water and ensuring that it meets the desired quality standards.

4. 5000LPH reverse osmosis system

5000LPH (liters per hour) RO (reverse osmosis) unit is a type of filter used in a reverse osmosis system to remove impurities from water. The RO membrane is a thin, semipermeable membrane that is typically made of polyamide, a type of synthetic polymer. The membrane is designed to allow water molecules to pass through it while blocking the passage of larger contaminants such as suspended solids, bacteria, and viruses.

The RO membrane is an essential component of an RO system and is typically used in conjunction with other types of filters, such as quartz sand filters and activated carbon filters, to provide a multi-stage filtration process that removes a wide range of contaminants from the water.

RO systems are commonly used in a variety of settings, including residential, commercial, and industrial, to provide high-quality, purified water for drinking, cooking, and other applications. The use of an RO membrane in an RO system can help to improve the overall quality of the purified water and ensure that it meets regulatory standards for purity.