FOB PRICE $11670

The price do not included air compressor and air dryer air filter air tank.

What is this price included?

- Automatic preform loading and conveyor system/ 1SET

2. Automatic 1 cavity 2-10liter bottle blowing machine/ 1SET

It is an 2 liter to 5 liter pet bottle automatic blow moulding machine for making plastic pet bottle. High automaticly and just need 1 worker. Capacity is 400-500bottles per hour.

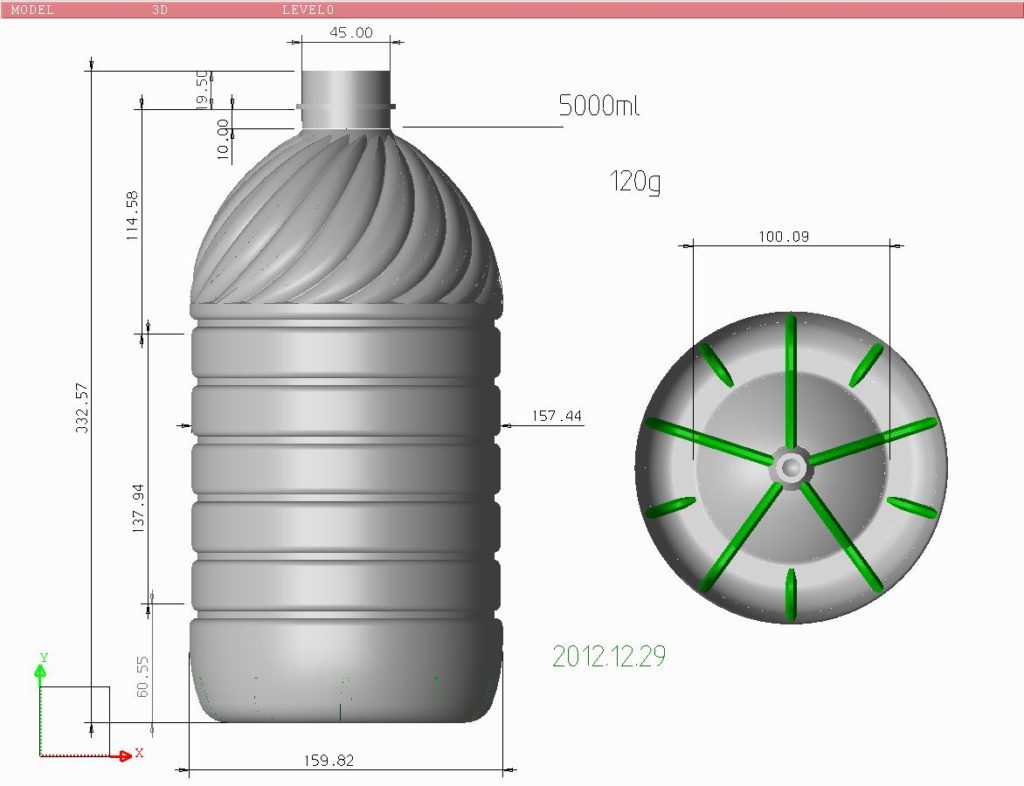

parameter of 5 Liter Blow Moulding Machine

| Capacity | 500-700pcs/h |

| Bottle Volume | ≤5000ml |

| Bottle diameter | ≤160mm |

| Bottle height | ≤300mm |

| Bottle Neck diameter | ≤80mm |

| Power voltage | 380V/220V 50/60HZ 3phase |

| Installed power | 26kw |

| Really use power | 6.5kw |

| Size(L×W×H) | (3200×1750×1900)mm |

| Weight | 2000kg |

What machine used to make 2L-10L water bottle?

video of bottle blowing machine make plastic pet bottle

How To Make 5L pet plastic Bottle ?

The pet bottle blow molding machine materials is hollow tube which also called pet preform.

The preform loading and feeding machine will automatic loading preform to the machine. Then it will automatic heating the preform to idea temperature. Then moving to the mold. The machine will blow are into the preform and blowing the preform into plastic bottle according to the mold shape.

Design blow mold

The bottle design will decide the mold shape. It is very important to do an nice design. So that final bottle will be clear and nice.

Produce Perfect clear Plastic bottle

Good quality blow molding machine not only lifetime long, but also produce out good quality plastic bottle which like art.

5 Liter Blow Moulding Machine Features:

- Reasonable design, full automaticlly control, save power and labor.

- Feeding system carries the preforms by robot arms automatically.

- Infrared oven heater adopts the quartz lamp to heat the PET tube.

- Fully automatic process with low investment, high efficiency,quick and safe for operation,

- easy for maintenance.

- Adopting high quality components