fOB PRICE $148,780

What this price included?

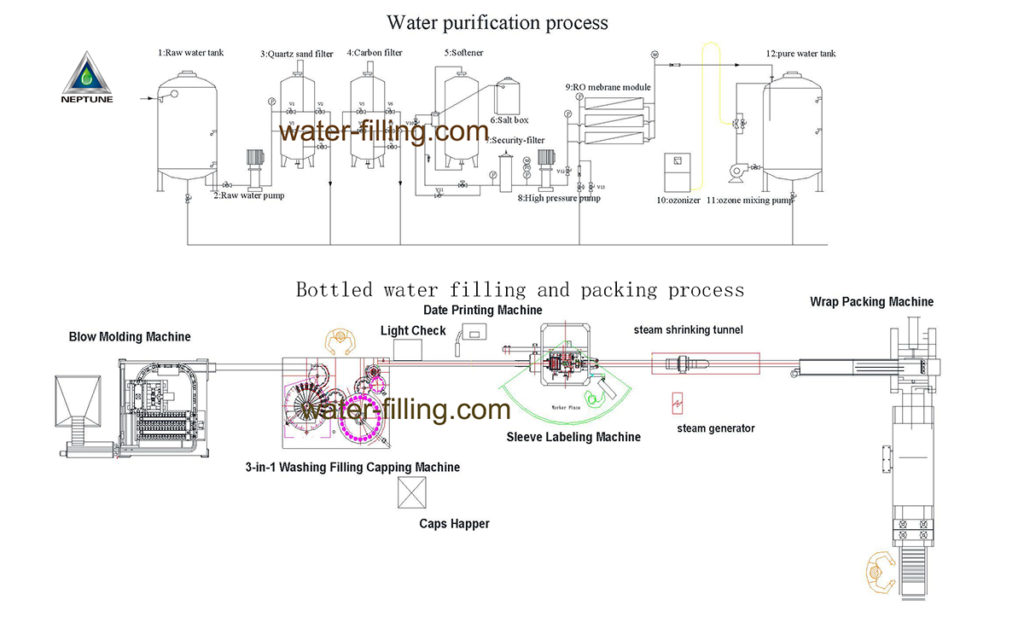

1.RO-1000I(5000LPH) RO WATER TREATMENT SYSTEM

2.BM-A8 FULLY AUTOMATIC BOTTLE BLOW MOLDING MACHINE

3.NF24-24-8 WASHING FILLING CAPPING MACHINE

4.HP-150 SLEEVE LABELING MACHINE

5.VIDEOJET 1210 INK JET PRINTER

6.NP-W250 AUTOMATIC THERMO SHRINKAGE PACKAGE MACHINE

The production capacity of this water bottling line is 8000 bottles per hour, based on 500ml bottles. It can easily switch between different volumes (200ml to 2000ml) with a mold change that takes only 2 hours. The entire line is highly automated, featuring a compact and aesthetically pleasing design.

It is user-friendly and easy to maintain, requiring only 8 workers. This bottling line is ideal for small water bottling plants, ensuring efficient production with a capacity of 8000-9000 bottles per hour.

Neptune Machinery’s 8000BPH Water Bottling Plant – a state-of-the-art facility designed for optimal efficiency.

The production process begins with workers handling materials, followed by a fully automated middle stage with no manual operations. At the end of the process, workers are involved in carrying the final goods to the storage room. This high-tech and efficient production line minimizes manual intervention, requiring fewer workers while maintaining a remarkable production capacity of 8000 bottles per hour. Neptune Machinery ensures a seamless and automated bottling experience, delivering top-notch quality and production efficiency.

What is the production capacity of the water bottling line?

For prduction 500ml bottled water : 8000 Bottles per hour

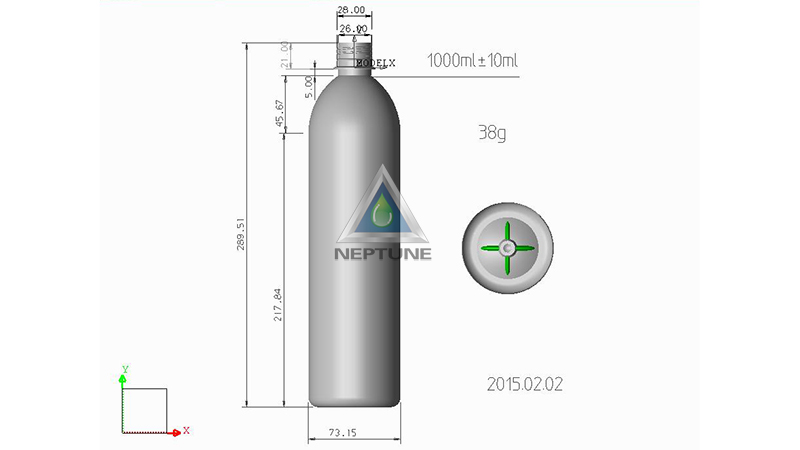

For Prduction 1000ml Bottled Water : 6000 Bottles Per Hourv

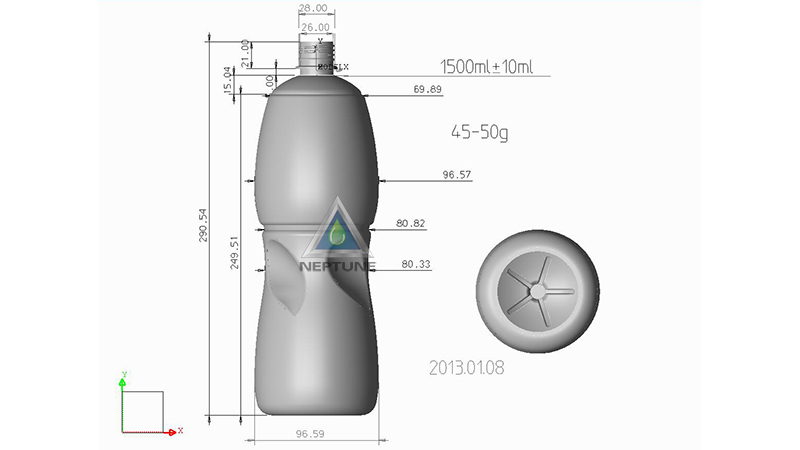

For Prduction 1500ml Bottled Water : 5000 Bottles Per Hour

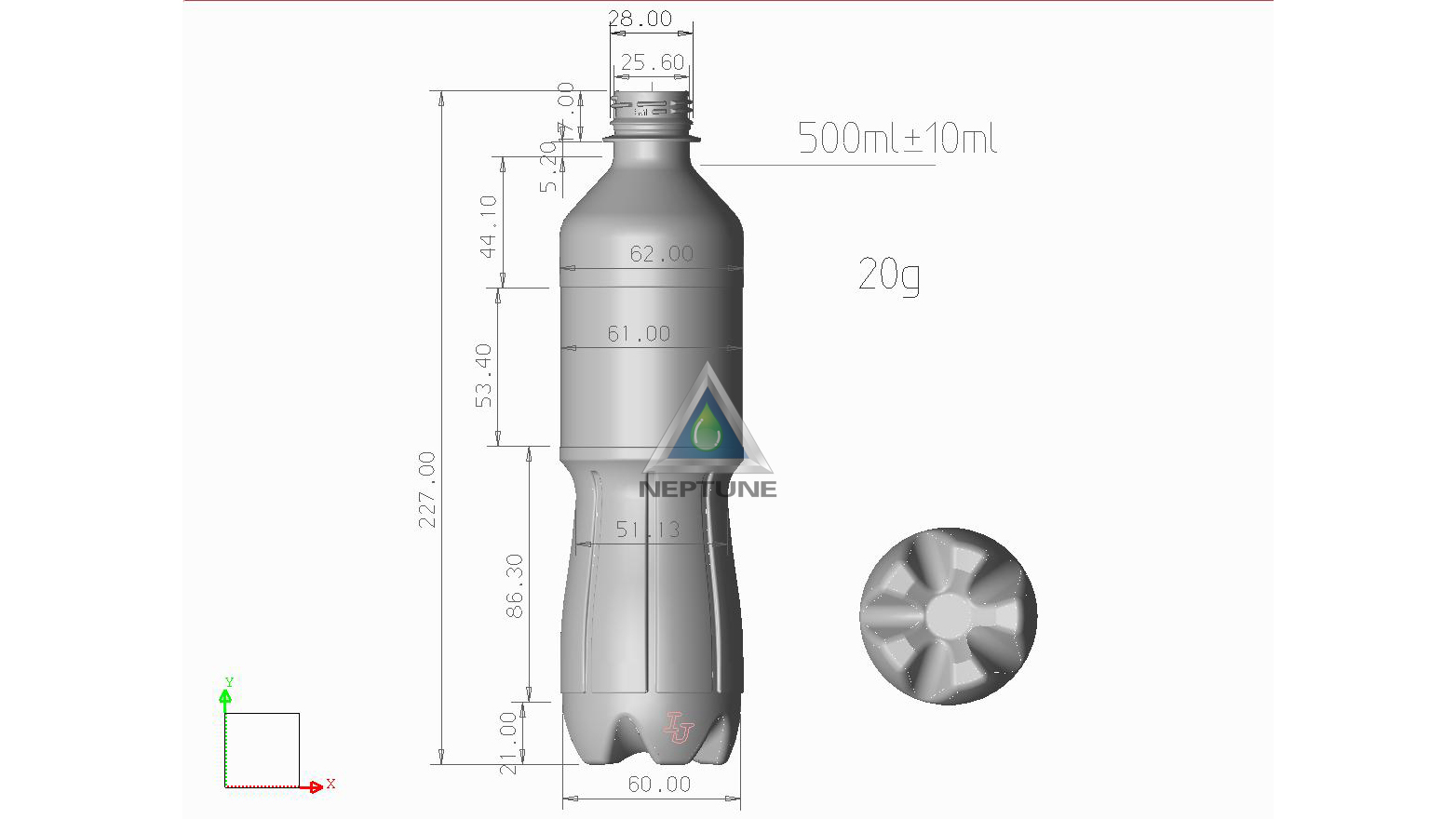

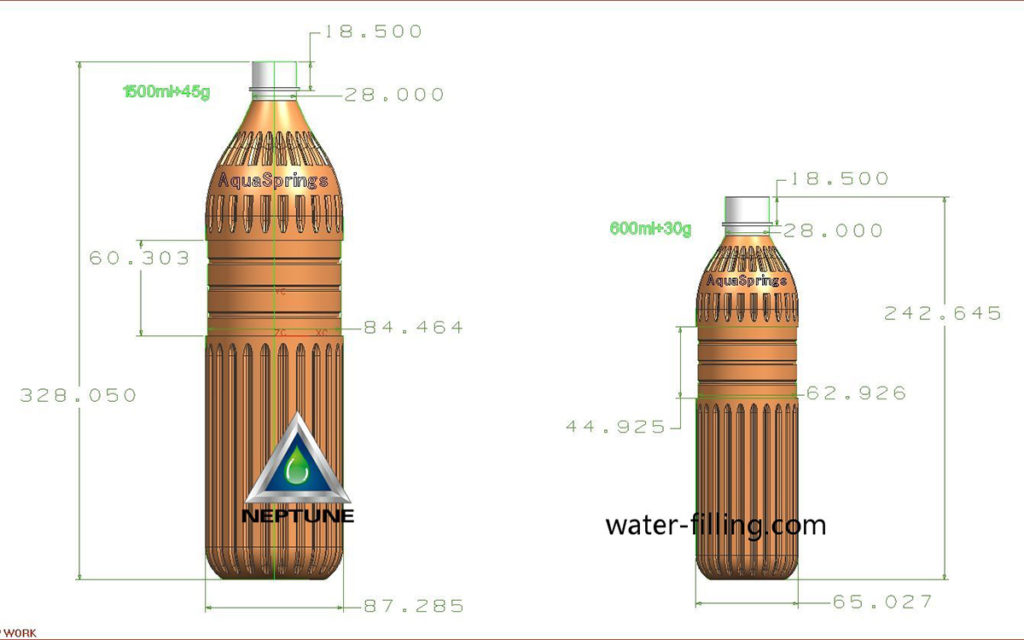

NEP-8000 water bottling plant through change mold can produce different volume and shape bottle water. And it also can fit different screw cap like 28mm 30mm and 1881 cap.

Machine list of 8000bph water bottling line

Why neptune 8000bph water bottling line?

100% Precise Water Bottle Design Free

Two way optional bottle design. We will scanning the really plastic bottle and produce the 100% precise bottle design according customer offer the really plastic bottle. Or offer 50psc worldwide bottle design for choice.

98% Precise Factory Room Design Free

Customer offer factory production room size and then confirm which bottling line. We will do the professional production layout which easy lead customer modify production room and final bottling line will according it to produce size and connection.

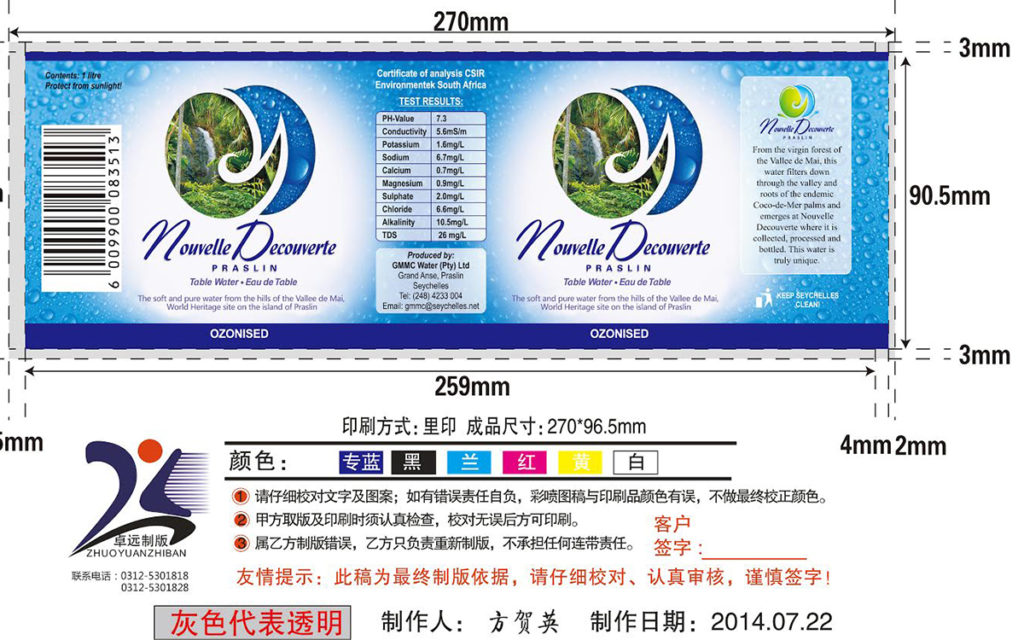

100% Precise Label Design Free

Offer logo design, and customer offer some information and picture which want show on the label.Then we will let professional label design do the creative design. Beauty and experiended. 100% free and do not have copyright issue.

How to running an water bottling line?

Power inquiry for bottled water factory

Supply power for bottled water factory

There are two way to supply power for bottled water factory.

Voltage stabilizer

First is directly supply government electricity. Use this way need fit an voltage stabilizer. Without an voltage stabilizer and running machine is high risk.

Unstable voltage will cause fatal injury or malfunction of equipment, affect production, cause delay in delivery, unstable quality and other losses. At the same time, it accelerates the aging of the equipment, affects the service life and even burns the accessories, so that the owner faces the trouble of needing maintenance or needs to update the equipment in a short period of time, wasting resources; in severe cases, safety accidents even occur, resulting in immeasurable losses.

Therefore, the use of voltage regulators is essential for electrical equipment, especially high-tech and precision equipment with strict voltage requirements.

Diesel generator power.

Second is use the diesel generator power supply eletricity. But the generator power cost extra cost, usually like 200kg with sound proof will cost about 20K dollar. And also cost diesel when running it. Of course, it will save the cost of eletricity payment.