5 gallon water filling machine is a type of automated machinery that is used to wash, fill, and cap 5-gallon containers with water. It is typically used in the bottled water industry to produce large quantities of purified water. The machine is made up of several different components, including a washing section, a filling section, and a capping section. The washing section uses water and detergents to clean the containers, while the filling section uses a filling nozzle to fill the containers with water. The capping section uses a capping machine to seal the containers with caps. The entire process is automated and controlled by a central control panel.

- Uses high-quality electrical components and material

- High automation, convenience, and reliability.

- Have a small size, lightweight design, and corrosion-resistant properties.

- Controlled by a programmable logic controller (PLC) for precise positioning and low power consumption.

- The machine is made of high-strength stainless steel and non-toxic materials for durability and safety.

Parameter

1. Production optional: 60BPH-600BPH

2. Volume of bottle: 3 Gallon-6Gallon

3. One machine only can use for one kind of bottle

4. Drink Kind: Mineral Water, Pure Water, Spring Water.

5. Function: Rinser Bottle, filler water, capper bottle.

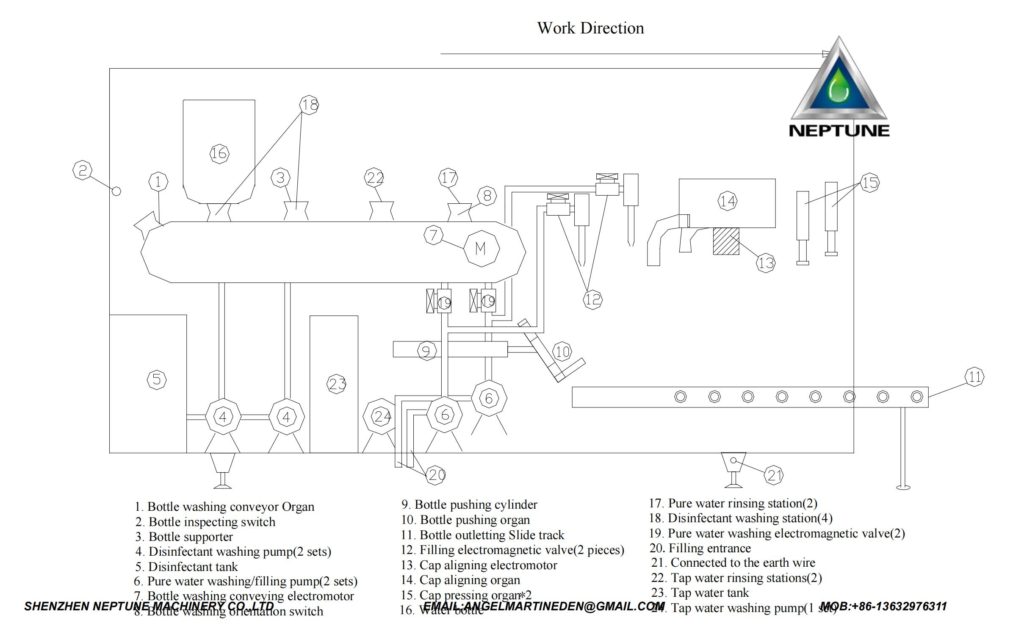

Working direction

Worker just need turn over load empty 20ltr plastic bottle into machine.

It have 4 row washing station. 1th and 2th washing station are disinfection. You can setting it use food-grade NaOH washing in case the recycle jar inside have chemical. 3th washing station is city water push inside washing. 4th washing station is pure water washing.

Then the 20 ltr jar machine will flip the bottle 180 degrees and filler pure water into the bottle. The machine come with water pump and PLC. The filling time can be setting easy by button or by PLC so that can adjust filler water level.

Then filler well bottle water conveyor to pressure capper. The machine have an cap tank which can hold an box cap. The cap will automatic take turn to pressure on the bottle mouth.

Video of 5 Gallon filling machine

According HCCAP of purified bottled water produce, human being is the pollution, Expect worker putting bottle and final worker carry the final product, Dot not all human being touch the bottle or bottled water at any process of producing.

Why Buy Neptune 5 Gallon Jar Water Filling Machine

The design of neptune 5gallon filling machine are simple and smart.

Spart part supplier keeping updated and our quality is keeping updated.

Industrial scale advantage. Thousands spare part supplier location each other. Spare part price and quality keeping compete. Price transparent and reduce. Quality updated every year.

Main frame is consisted by a stainless steel tube, Structure is beautiful and strong. The sub-machine welded to the main frame.It set up separate work area and support role.

Running An 5 Gallon Bottled Water Station In House

If you are planning on running a 5-gallon bottled water station in-house, there are several things you will need to consider. First, you will need to ensure that you have the appropriate equipment, such as a 5-gallon water washing filling capping machine, as well as a source of purified water. You will also need to have a designated area for the bottled water station, as well as the necessary storage and transportation facilities for the filled bottles. Additionally, you will need to obtain any necessary licenses or permits from your local government to operate the bottled water station. It is also important to develop a plan for marketing and distributing the bottled water to customers.

Rinse Parts:Consisted Of The Transmission Flushing,The Water Tanks,The Rinse Water And Else

Transmission flush:

The agency with the complete machine frame as the basic support, drive motor and the drive bearing fixed to the support frame. Through the drive motor drive the axis, the passive axis,and two pairs of nylon and stainless steel chain sprocket of the axis.And then through the stainless steel chain drives the washing cup (ie bottles of care) which had fixed in the stainless steel chain, so as to achieve the purposes that transfer bottles into Washing station for decontamination.

Water tank

The machine is equipped with two stainless steel tank(a dress with a disinfectant solution, and the other costumes for water purification).They are use to collection solution which recycled, post-rinse solution bottle

The sterile water and the purified water without water tank,they are return to fresh water tank after rinse bottles. Thers is a water level in the water tank,through the water level can directly observed the level of the solution

Rinse water:

The pipeline of the machine bonding together by special food-grade water tube.

The disinfectant and sterile water (pure water) wash and the sterile water (purified water) filling water are separately. Disinfectant supply by the water tank,the sterile water (pure water) supply by the outside of the machine.The sterile water (pure water) washing and the water filling are divided into two system, evey system has a solenoid valve.

After finished cleaning or filling , the respective solenoid valves and pumps shut down.

Filling And Sealing : The Filling System, Capping System

- Push the bottle and filling system:

Push the machine is connection by the cylinder and the stainless steel push push bottle bottle rack, the holder mounted on the rack.

Filling system consists of stainless steel filling head, filling and filling system solenoid valve position adjustment board composition. - Management cover-Sleeve cover-Gland system:

Caps slide in the the cover of the area through through the cover slide track management to waiting for hanging, when there is a filled water bottle through the cover of the area, The caps set in the mouth of the bottle by the anti opposite direction of the force of ther bottle and cover of the device running, At the same time the bottle go into the gland area. The gland is consist of the gland plate, gland architecture into a cylinder and gland adjustments. When the filling gland starts to work the gland starts capping(the gland device can adjust up and down depend on the level of water bottles)

Note: To make sure the device more stable and reliable in the process performance. The bottle cap in the management control should kept dry, there can not have a drop of water . The water will causing leakage which will lead to the machine does not work. - Out of the bottle conveyor system:

The transmission system is consists of a bottle of the bottle rack, push the bottle and the bottle slide cylinder form. After cleaning and disinfection,the water bottles was truned to the out bottle slide by the bottle drive mechanism. The bottle cylinder moves the water bottle onto the filling position, then the next bottle which had been cleaned and disinfection in turn sent it to the cover of area and gland area. Finally,the bottle output of the machine.