Capacity for choice

200Bottles/H Plant

Complete 5 gallon 200bottles/h water bottling plant for sales

$13,430

Included as follow:

Cap Pulled Machine … 200 Bottles/H $ 1580

Outside & Inside Brush Machine … 200 Bottles/H $ 4680

Bottle Loading Machine … 200 Bottles/H $ 1500

Cap Washing & Loading Machine … 200 Bottles/H $ 1500

5 Gallon Water Filling Machine … 200 Bottles/H $ 3170

Steam Mouth Sealing Machine … 200 Bottles/H $ 1000

300Bottles/H Plant

Total cost of the 300 bottles/h 5 gallon bottled water filling plant

$14,640

Included as follow:

Cap Pulled Machine … 300 Bottles/H $ 1580

Outside & Inside Brush Machine … 300 Bottles/H $ 4680

Bottle Loading Machine … 300 Bottles/H $ 1500

Cap Washing & Loading Machine … 300 Bottles/H $ 1500

5 Gallon Water Filling Machine … 300 Bottles/H $ 4380

Steam Mouth Sealing Machine … 300 Bottles/H $ 1000

450Bottles/H Plant

The price of 450 bottles/h 5 gallon jar water filling plant

$19,770

Included as follow:

Cap Pulled Machine … 450 Bottles/H $ 1920

Outside & Inside Brush Machine … 450 Bottles/H $ 5350

Bottle Loading Machine … 450 Bottles/H $ 1840

Cap Washing & Loading Machine … 450 Bottles/H $ 1640

5 Gallon Water Filling Machine … 450 Bottles/H $ 7770

Steam Mouth Sealing Machine … 450 Bottles/H $ 1250

Neptune Machinery is China professional manufacture of 5-gallon water bottling machine plant, supply a solution for refilling 3 to 6-gallon bottled water.

5 Gallon water bottling plant included a capper removal machine, outside and inside bottle brusher washing machine, bottle washing and filling capping machine, and bottle-mouth sealing machine.

- Premium Materials: All component in contact with water is high-quality 304L stainless steel, ensuring compliance with stringent food-grade standards and offering exceptional resistance against ozone.

- Thorough Rinsing: The incorporation of nozzles ensures a comprehensive rinsing process, guaranteeing the cleanliness of the bottles.

- Efficient Cleaning System: A fast cycle system is employed for heated alkali rinsing, significantly reducing electricity consumption and contributing to operational efficiency.

- Automated Operation: The entire system is controlled by a PLC (Programmable Logic Controller), enabling fully automatic operations. This not only streamlines the bottling process but also enhances precision and reliability.

The plant operates under the efficient control of a PLC system, guaranteeing fully automatic and streamlined operations. This includes an advanced nozzle-based rinsing system, ensuring thorough cleaning while minimizing water usage. Additionally, the plant optimizes electricity consumption during heated alkali rinsing cycles, contributing to sustainability and cost-effectiveness.

Designed to produce clean and high-quality 3, 5, and 6-gallon bottled water, Neptune Machinery’s plant emphasizes reliability, efficiency, and adherence to industry standards. The automated processes enhance productivity, while the use of premium materials ensures longevity and robust performance.

With a focus on sustainability, the plant encourages the reuse of bottles through a rigorous cleaning regimen. This not only aligns with environmental consciousness but also meets the demand for high standards in the bottled water industry.

Neptune Machinery’s 5-gallon water bottling machine plant stands as a testament to innovation, quality, and efficiency in the production of large-volume bottled water, providing a turnkey solution for businesses seeking a direct and reliable manufacturing approach.

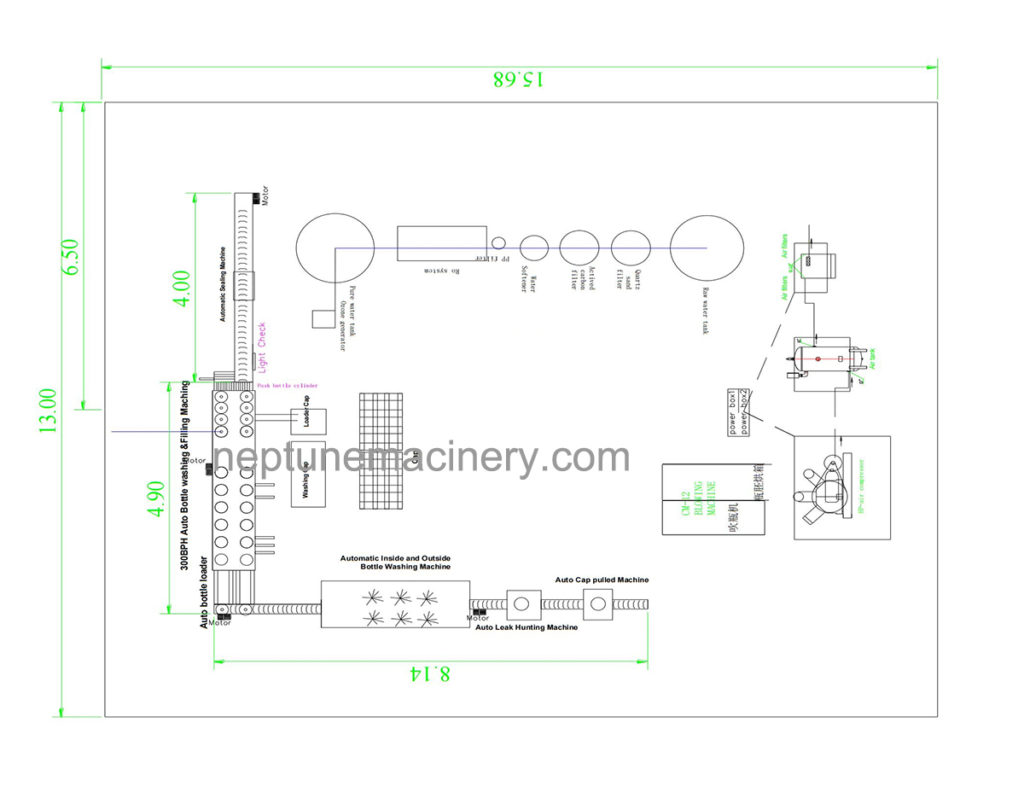

Layout Of 5 Gallon Water Bottling Machine Factory

Key Features :

- PLC Control: PLC-controlled, integrating the functions of 3/5 gallon bottle washing, filling, and capping into a single machine.

- Compliance Standards: Manufactured in compliance with the standards set by the China Purified Water Industry Association and inspired by the latest international machine designs.

- Technological Advancements: Incorporates advanced technology for high automation, easy operation, and reliable performance.

- Compact and Aesthetic Design: The machine is characterized by a small size, light weight, and aesthetically pleasing appearance.

- Quality Materials: Utilizes key components from reputable Chinese and international manufacturers, ensuring durability and reliability.

- Anti-Corrosive: Resistant to corrosion, ensuring longevity and maintaining performance over time.

- Thorough Disinfection: Incorporates effective disinfection measures to ensure the purity and safety of the bottled water.

- High-Quality Production: The use of high-quality materials, including non-toxic PP plastic, contributes to the production of clean and high-quality bottled water.

The water bottling machine by Neptune Machinery combines advanced technology with practical features, making it an ideal choice for efficient and reliable 3/5 gallon bottle washing, filling, and capping processes.

How does an 5 gallon Water Bottling Machine Plant running?

Process

- Removed the cap

- Leak check

- Brush washing the outside and inside of the bottle

- Automatic turn 180degree loading

- NaOH and pure water push washing

- Auto filling and pressure capping

- Cap washing and loading

- Mouth an label sealing the bottled water

Automatic Caps Removal Machine

It is applicable for the 5 gallons recycle bottle cap pulled and absolutely necessarily for the empty bottle retreating assembly with the integration of simple configuration, effective cap pulled, little dilapidation to the cap, small distortion and efficiency for using.

Automatic Bottle Internal&External Brush Washer

Automatic Bottle Internal and External Brush Washer is an inside and outside washing device for 5 gallon recycled bottle which is manufactured according to the clients’ requirement. After coming into the market, it is well accepted by water equipment industry from home and abroad.

Auto Cap Feeding & Washing Machine

Washing Cap and Loader Cap Machine manufactured by our company. This machine, a newest practical product, is manufactured in order to consummate a complete set of product line.

Automatic Bottle Loader Machine

It is not only with the advanced technology, high automatization easy operation and reliable performances as the genuine device from abroad, but also features with small size, small weight and beautiful appearance, anti-corrodibility, thorough disinfection, effective anti-air pollution and high quality.

3/5Gallon Bottle Washing Filling Capping Machine XG-100J(60-900BPH)

PLC-Controlled Microcomputer Automatic Bottle Washer & Filler manufactured by our company, which concentrates the functions of bottle washing, filling and capping with 5 and 3 gallons on one set of machine and manufactured with the standard of America Drinking Water Industry Association & with reference to overseas newest type of equipment.

Mouth sealer

The equipment is adopted Heat-generating Tube to shrink the membrane sticking to the cap.It is manufactured according to the clients’ requirement which is used for bottles of 3gallon or 5 gallon after filling. After coming into the market, it is well accepted by water factories from home and abroad.

Refill 5 Gallon Bottled Water Business

Refill 5 Gallon Bottled Water Business

A 5gallon bottled water weight 20kg, so that dilivery to customer is an hard work.

A big cost of 5gallon bottled water business is dilivery the bottled water to consumer home or office.

Most factory running the 5gallon business by themseleves without channel or agent. Because a factory everyday just produce 1600bottles. And every bottle is heavy, so that factory mostly builded closed to the city or town. Means factory closed to the customer.

Factory running sales and dilivery themselves is this business natural features.

How profit of an 5 gallon bottle water business?

Bottled is reused. Cap and water materials cost lesst than USD 0.2

An 20liter bottled water wholesales price ranging from 1dollar to 4dollar. Most usually sales at 2dollar.

Worker dilivery 1psc 20l bottled water to customer salary is USD 0.3

So that 1psc 20l bottled water gross profit is USD 1.5. And per day 1600bottles. It can profit USD 2400 per day. Any customer not only working time need drinking pure water but also holiday need drinking pure water. One year it can profit about USD 87600

Why still now have chance to setup an 5 gallon water bottling machine plant ?

Setting up a 5-gallon water bottling machine plant remains a viable opportunity for several reasons:

- Localized Demand: In smaller towns and cities where the population might not support a large-scale facility by major brands, there is a growing demand for safe and pure 5-gallon drinking water.

- Delivery Challenges: The weight of each 5-gallon bottle makes long-distance transportation expensive and time-consuming. Establishing a local plant reduces delivery costs and enhances efficiency.

- Consumer Preference: Many consumers prefer fresh, safe, and locally sourced pure water. Building a plant in smaller communities allows catering to this preference.

- Market Gap: Large brands often focus on densely populated areas, leaving a market gap in smaller regions. Entrepreneurs can capitalize on this gap by providing a local solution.

- Economic Opportunities: Small towns and cities might offer economic advantages, such as lower operating costs and potentially less competition, making it financially attractive to set up a bottling plant.

- Increasing Population: Smaller areas may experience population growth over time, leading to a rise in demand for essential products like safe drinking water.

In summary, the opportunity to establish a 5-gallon water bottling machine plant persists due to localized demand, logistical challenges faced by major brands, consumer preferences, market gaps, economic advantages, and the potential for population growth in smaller communities.

Benefits of 5gallon pure bottle water business:

- University Supply: Ideal for providing clean water to universities and educational institutions.

- Profitability: High potential for profitability, especially with large-volume production.

- Reusable Bottles: 5-gallon bottles can be reused for up to 2 years, contributing to sustainability.

- Space Efficiency: Compact units allow for efficient use of plant space.

- Environmentally Friendly: Minimal environmental impact, ensuring no pollution.

- Cost-Effective Setup: Lower initial setup costs compared to larger-scale operations.

- Job Creation: Street sellers can distribute the bottled water, contributing to job creation.

These advantages highlight the economic viability, sustainability, and social impact of a 5-gallon pure bottle water business.

How Neptune Machinery Can Help Establish Your 5-Gallon Bottled Purified Water Plant:

- Turnkey Solutions: Neptune Machinery provides comprehensive turnkey solutions for 5-gallon water bottling plants used globally.

- End-to-End Assistance: From the initial concept to the operational phase, we support you in every step of setting up your 5-gallon purified water plant.

- Profitable Business: We offer insights into the profitability of the 5-gallon bottle water business, guiding you through the process.

- Consultation: Reach out to us through calls or emails for detailed information and consultation on starting and operating your 5-gallon bottled water plant.

- Equipment Supply: Neptune Machinery can provide essential equipment such as reverse osmosis water treatment machines and bottle blow molding machines crucial for a 5-gallon bottle water plant.

Our expertise and turnkey solutions ensure a smooth and successful establishment of your 5-gallon bottled purified water business.

Related machines

5Gallon bottle blow molding machine

Produce your own unique jar bottle in your own factory. Save freight cost.

Pure water RO treatment Machine

RO system removed everything of raw water to produce the pure water. Supply pure water for the 5gallon bottled water production plant.