Fob price $ 9,800.00

what this price included?

- Wrap film machine / 1SET

- Shrink machine / 1SET

Efficient and Cost-Effective Solution

Automatic water bottle shrink wrap machine tightly bundles 6/12/24 bottles using heated PE film, ensuring a secure water bottle package for storage or transport. Here’s how it works:

- Film Application:

- The PE film is applied to the bottles using the machine, forming a tight package around them.

- Heating Process:

- The PE film-covered bottles go through an oven where the film is heated, ensuring a secure and snug fit around the bottles.

- Shrink Tunnel:

- Subsequently, the package passes through a shrink tunnel where the film undergoes further heating. This causes the film to shrink and tightly encase all the bottled water in one package.

- Wide Application:

- This machine is versatile and finds applications in packaging bottle beverages, medical-chemical products, and bottled water. It accommodates various bottle shapes, including those without pallets, cartons, and different geometries.

- Advantages:

- The machine offers cost savings as it primarily utilizes PE film, which is a cost-effective material.

- It is equipped with a PLC automatic controller and a user-friendly interface, ensuring a reliable and safe operation.

- The hot wind recycle structure adapts to different thermal films, including color printing, providing flexibility in packaging design.

- The machine is designed for minimal material waste, making it an environmentally friendly choice.

- Labor Efficiency:

- The machine connects directly with the conveyor belt and autonomously arranges the bottled water, reducing the need for manual labor. This feature makes it particularly suitable for small plants and businesses.

- Popularity in Africa:

- The machine is widely appreciated in African countries for its efficiency, cost-effectiveness, and suitability for small-scale operations.

Two main part of Automatic bottle shrink wrap machine

1. Wrap Film machine

The bottle clamp will arrange 3 or 4 line bottled water enter. Then the setting well clampboard and buffle will decide how many bottled water one package.

The wrap film unit will wrap and cutting film well. And let the package bottled water enter the next shrinking tunnel

| Power | 3kw |

| Packing speed | 0~13pcs/min |

| Conveyer loading | 20kg |

| Weight of film roller | ≤15kg/roller |

| Max. packing size | 500(L)×300(W)×400(H)mm |

| Min. packing size | 250(L)×50(W)×100(H)mm |

| Machine size | 1060(L)×1600(W)×1930(H)mm |

| Weight of machine | 350kg |

2. Shrink machine

The package bottled water will film go through this tunnel by conveyor belt. And the film will auto shrinking when it face hot temperature. So that it will got tight the bottled water.

| Power | 20KW |

| Conveyor speed | 0-10m/min |

| Conveyor load | 50kg |

| External size of the machine | 2500*820*1680mm |

| Packing size | 500*400mm |

| Thick of film | 0.03-0.25mm |

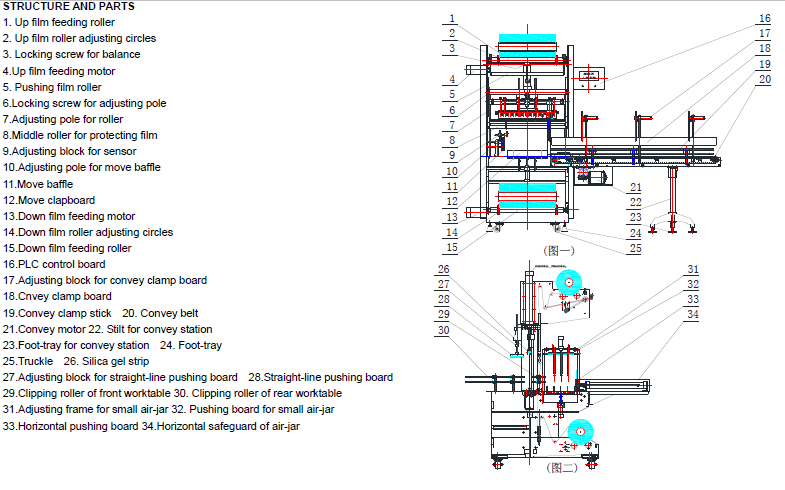

Structure and parts

Equipment consisits of following parts:

Bottle conveyor device: transfer goods which need package.

Block bottle, dispart bottle device: transfer packages in separateway and control strock of package.

Block bottle position inspecting device: separate bottles to package and consequent bottles.

Pushing bottle, guild bottle device: Pushing bottles to sealing and cutting.

Film fix length conveyordevice: transfer package film.

Sealing&cutting device: seal and cut package film.

Hot wind recycle device: To fulfill thermal shrinkage function.

Heat resistant conveyor device: Transfer finished products under high temperature, and fulfill thermal shrinkage function.

Finished product storage device: storage products temporally.

Colling device: Cool product so that convenient transfer products to required position.

PLC control system: Automatic control

The video of wrap shrinking packing machine work

The bottle and box which need to be packed is transferred to block bottle plate along dispart bottle device.

The bottle conveyor will stop when photoelectrical inspector on the top send out a signal, while block bottle plate stand back to release pressed force of bottle.

The separate plate up rises to separate packing bottle and bottles to be packed. Push bottle device pushes packing bottle and film along with guils bottle device to sealing&cutting position, meanwhile pushes the last package onto conveyor of thermal shrinkage equipment, meanwhile film feeding device is working.

Then the thermal sealing&cutting move downward, to sealing and cutting. The package which been pushed onto thermal conveyor is go ahead and finish thernal shrinking function, finally it goes to strong device after colled by cold wind.

The above processing fulfills automatic packing.

The above movements are all done by air cylinder under PLC control, except conveyor system.

Bottle Shrink Wrap Machine – WORKING PROCESS

The automatic water bottle shrink wrap machine is designed with precision and efficiency in mind, featuring the following key components:

- Bottle Conveyor Device:Efficiently transfers goods requiring packaging along the production line.

- Block Bottle, Dispart Bottle Device:Transfers packages in a separate way, maintaining control over the stock of packages for organized handling.

- Block Bottle Position Inspecting Device:Separates bottles for packaging, ensuring a smooth and sequential process.

- Pushing Bottle, Guide Bottle Device:Pushes bottles towards the sealing and cutting stages with precision.

- Film Fix Length Conveyor Device:Transfers the packaging film with a controlled and consistent length.

- Sealing & Cutting Device:Seals and cuts the packaging film effectively, creating a secure and uniform finish.

- Hot Wind Recycle Device:Utilizes hot air for thermal shrinkage, ensuring optimal packaging results.

- Heat Resistant Conveyor Device:Transfers finished products under high temperatures, contributing to the thermal shrinkage process.

- Finished Product Storage Device:Temporarily stores finished products, optimizing the workflow.

- Cooling Device:Cools products as needed, facilitating the transfer of products to their designated positions.

- PLC Control System:Incorporates a sophisticated Programmable Logic Controller for seamless and automatic control of the entire shrink wrap process.

Wrap film package vS Carton Case Package

Wrap Film Package

- Package machinery cheap

- Package film cheap

- Package not easy damage, waterproof and dirt-proof

Carton Case Package

- Fashionable appearance

- Environmental protection

- Supermarket and shop like it

- Carton case easy for printing Patterns and slogans

NEPTUNE Automatic Water Bottle Shrink Wrap Machine offers a cost-effective alternative to traditional carton packaging machines, providing several advantages:

- Affordable Investment:Priced at less than $10,000, the machine offers a budget-friendly solution for your packaging needs.

- Low Film Cost:The shrink wrap film used in the process is economical. For packaging 24 bottles, only 5g of film is required, costing approximately $0.11. In contrast, a carton case for the same quantity can cost around $0.45.

- Savings Comparison:Compared to an automatic bottled water carton packaging machine, which can cost around $30,000, the shrink wrap machine presents a substantial cost savings.

- Consumer-Friendly:Supermarkets and shops often prefer carton cases for resale, but consumers typically purchase individual bottles. The shrink wrap allows for easy access to single or double bottles from the shelf, enhancing consumer convenience.

NEPTUNE Automatic Water Bottle Shrink Wrap Machine: A Cost-Efficient Solution for Streamlined and Economical Packaging.

Cost Savings with Wrap Film Shrink Packaging: A Smart Choice for Bottle Water Factories

The decision to use wrap film shrink packaging for bottled water comes with significant cost advantages. Here’s a breakdown of the savings:

- Machine Cost:Automatic bottled water wrap film and shrinking package machines cost less than USD 10,000, while an automatic bottled water carton package machine is around USD 30,000.

- Film Cost:

- Wrap film costs approximately USD 2.5 per kg, and 1 kg can package 22 pieces. This results in a per-piece cost of USD 0.005 for wrap film.

- In comparison, a carton case for 24 pieces of 500ml bottled water costs USD 0.45, resulting in a per-piece cost of USD 0.0189.

- Cost Difference:

- The cost difference per 500ml bottled water between wrap film and carton case is USD 0.0139.

- Annual Savings:

- For a bottled water factory producing 3 million bottle water per year, the material cost difference amounts to USD 41,818.

Choosing wrap film shrink packaging not only leads to substantial cost savings but also aligns with the preference of many supermarkets and shops. Additionally, consumers typically focus on the individual bottle rather than the packaging, making wrap film a practical and economical choice for bottle water manufacturers.