First start bottled water business to making plastic bottle with BM-S2 bottle blowing machine. Come with mold-chiller for continued produce high quality bottle.

FOB PRICE $5900

Add mold-chiller $1300

TOTAL FINAL $7300

What this price included?

| NO | NAME | QC | TOTAL USD |

| 1 | BM-S2 2CAVITY BLOW MOLDING UNIT | 1 SET | USD 1,900.00 |

| 2 | ROTATING OVEN | 1 SET | USD 1,200.00 |

| 3 | 0.7m3 SHANGHAIR High pressure air-compressor | 1 SET | USD 1,500.00 |

| 4 | Air Dryer | 1 SET | USD 600.00 |

| 5 | Air Filter(1.0m3/min 30kg); Brand Hangzhou Tiancheng | 2 SET | USD 300.00 |

| 6 | Two cavities blow mold (200-2000ml) | 1SET | USD 400.00 |

| 7 | Spare part & High pressure Pipe | 1SET | FREE |

| 8 | Mold-chiller (Cooling the mold for continued produce high quality bottle) | 1SET | USD 1300 |

First start bottled water business to making plastic water bottle with this bottle blowing machine. It is the smallest and cheapest bottle blowing machine in the world.

Continued blowing working lead the mold temperature high. It will effect the plastic botttle yield. So that it is very important to fit an air chiller for the mold. NEPTUNE fit the expensive Air-chiller for the blow mold. It do not neect extra big water tank circulating water cooling the mold. So that will not leak water lead factory wet.

💡 Why Choose Us?

- ✔️ Unbeatable Price: We offer a price point that makes quality PET bottle production accessible to businesses of all sizes.

- 🌍 Global Presence: Trusted by companies worldwide, our machines are a testament to our commitment to excellence.

- 🛠️ Simple Design, Superior Performance: Our semiautomatic PET bottle blowing machine is designed for ease of use and requires minimal maintenance for consistent, reliable performance.

🌟 Affordable Excellence:

Semiautomatic PET Bottle Blowing Machine combines cutting-edge technology with an unbeatable price, ensuring that businesses of all sizes can enjoy the benefits of superior PET bottle production without breaking the bank.

🚀 Key Features:

1. Semiautomatic Precision:

- Achieve precision in PET bottle production with our semiautomatic machine. It strikes the perfect balance between automation and user control, making it ideal for a range of production needs.

2. High-Quality PET Bottles:

- Don’t compromise on quality. Our machine is engineered to deliver PET bottles with consistent quality, meeting industry standards and exceeding expectations.

3. Simplified User Interface:

- Embrace the simplicity of operation. Our machine features a user-friendly design, making it easy for operators to navigate and maintain. Efficiency doesn’t have to be complicated.

4. Cost-Effective Design:

- Experience the benefits of affordability without sacrificing performance. Our PET bottle blowing machine is competitively priced, ensuring a quick return on your investment.

5. Mold-chiller:

- The mold-chiller will cooling the blow mold for continued produce high quality bottle

🌐 Applications:

- 🥤 Perfect for Beverage Manufacturers: Ideal for producing PET bottles for various beverages, including water, juices, sodas, and more.

- 🏭 Versatile for Different Industries: Adaptability makes our machine suitable for diverse industries requiring PET bottles.

This pet bottle blow molding machine can produce two plastic bottle once. It is very mature PET bottle making machine. A lot bottled water company first start making plastic bottle with this bottle blowing and making machine. It is the smallest and cheapest bottle blowing machine in the world.

It is widely used to produce 100-2000ml carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle etc.

Technique Parameter

| Product material | PET |

| Volume | 100ml to 2000ml |

| Theoretical output | 800 Bottles/h |

| Preform length | 15mm-350mm |

| Preform inner diameter | φ5mm-38mm |

| Max.mould plate Dimension(L x W) | 350x380mm |

| Max.mould thickness | 180mm |

| Clamping force | 45KN |

| Mould opening stroke | 160mm |

| Main blowing machine (L x W x H) | 160x60x161cm |

| Main blowing machine weight | 500Kg |

| Heater oven (L x W x H) | 187x63x145cm |

| Heater oven weight | 250Kg |

| Power inquiry total | 17.5kw |

Equipment list of water bottle making machine

Easy and safe use. It is the blowing plastic pet bottle part unit.

It is the heating oven which used to heating the pet preform.

The high pressure air compressor supply air for blowing the bottle.

Air dryer with 2psc filter which use to clean and purified the air from the air compressor.

It is used to cooling the blow mold. Make sure the bottle making process continued.

Through change blow bottle mold and can produce different shape and volume bottle.

Video of the PET Bottle Blowing Machine

It need worker manul insert pet-preform on oven and carry the heating well preform to the blowing unit.

And then need worker press the button to start blowing plastic pet bottle

Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the perform rotated and heated equally.

The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

The machine can be operated in the step-by-step mode and the semi-auto mode.

The machine is small with low investment, easy and safe to operate.

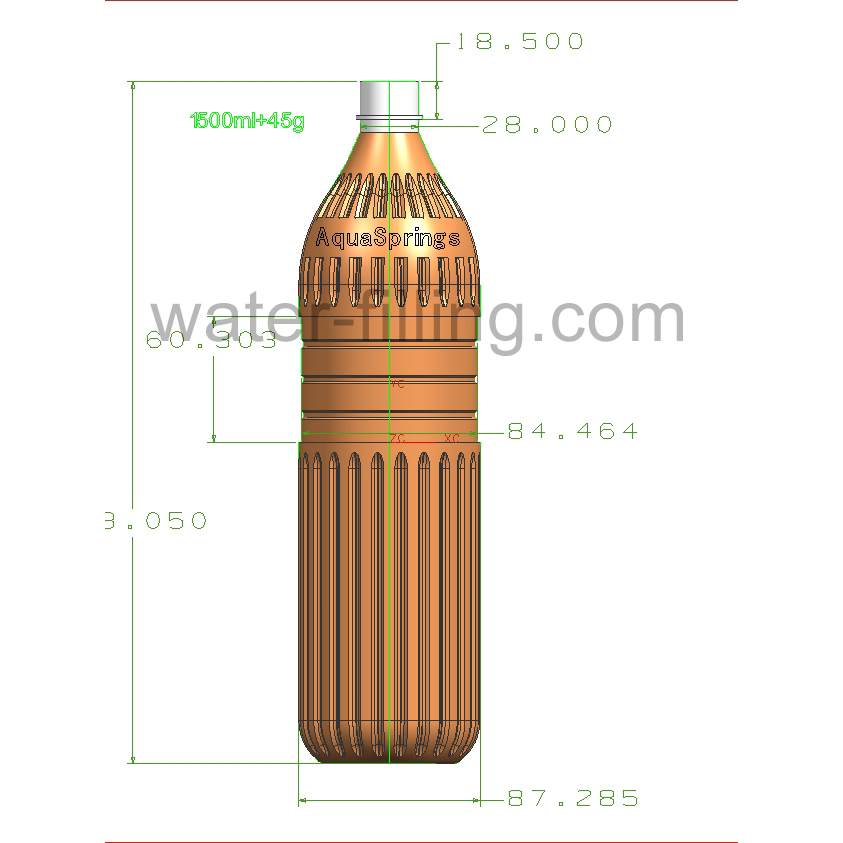

Got an beauty bottle design

NEPTUNE machinery have expert engineer drawing and design the plastic pet bottle. They are professional and experienced.

Every plastic bottle design mark and line must 100% clean when it prodution into an really pet plastic bottle.

The bottle design structure must good. So that will not easy fall down on conveyor belt of water production plant. Can not easy fall down shop freezer.

Got High quality Plastic Bottle

An beauty plastic bottle will attract consumer. When it show on Shelves of supermarket. People will been attract by it. And want touch it and have an detail look.Then maybe more purchasing. Anyway, an bottled water is not expensive. A little attract will let consumer buy it.