Complete Plant

FOB PRICE $29,410

It is an completely water bottling line included all necessary equipment from A to Z. What water bottling facility needed for setup a bottle water factory ?

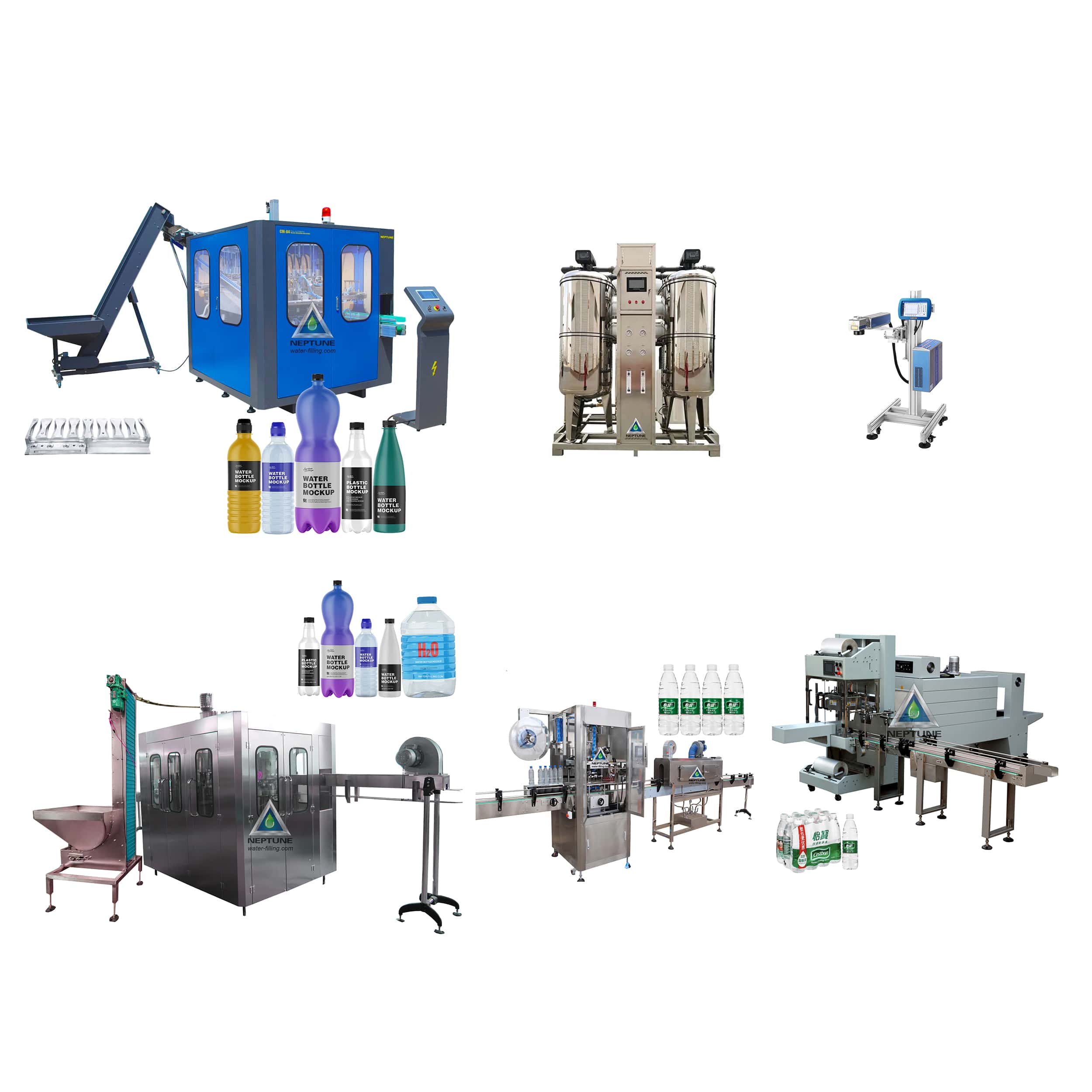

- 1. Bottle blowing machine

- 2. Bottle water washing filling capping machine

- 3. RO water purification

- 4. Laser code date printer

- 5. Bottle labeling machine

- 6. Bottle packing machine

WHAT NEP-1000 UPDATED ?

- Updated ink printer into auto laser code date printer. Laser printer do not need ink materials anymore.

2. 1000LPH RO water purification system updated into automatic valve, All pipe updated into stainless steel 304

| Capacity Production | 1000 Bottles/H |

| Product Bottle Volume | 200ml-2000ml |

| Power Inquiry | 70kw |

| Shipment Container | 1psc 40HQ container |

| Factory Inquiry Room | +70 square meter |

| Product | Pure bottle water, Mineral bottled water, Spring bottle water and other bottle drinks. |

Make your own Unique Plastic bottle & Bottle water

From A to Z completely water bottling plant widely use to bottle 200ml to 2000ml small bottle water.

NEP-1000BPH small water bottling plant is ideal for newcomers in the bottled water industry. Featuring smart design and essential functions, it offers a complete production line.

- Turnkey Solution: NEP-1000 provides a complete bottling line solution, covering all essential steps from bottle maker, water treatment, washing filling capping, labeling , date printer and package. It is turnkey solution from A to Z.

- Ease Use: The design focuses on simplicity and user-friendly operation, making it suitable for individuals with varying levels of experience in the industry. This ease of use contributes to a smoother production workflow.

- Easy Installation: NEPTUNE emphasizes easy installation, allowing entrepreneurs to set up the bottling plant quickly. Whole line just need 1 engineer cost 3days to finished installation. NEPTUNE support oversea installation .

- Versatility: NEP-1000 bottling line is versatile, accommodating different bottle sizes and shapes. This flexibility enables businesses to diversify their product offerings and cater to various market demands.

- Global Success: NEPTUNE’s track record of building a large number of successful water bottling projects worldwide reflects the reliability and efficiency of their bottling plant solutions.

- Efficient Production: NEP-1000 bottling plant is designed for efficient production, allowing entrepreneurs to meet market demand and scale their operations as needed.

- Cost-Effective: The bottling plant’s design considers cost-effectiveness, helping entrepreneurs manage initial investment and operational expenses efficiently.

- Proven Technology: With over 20 years of experience and continuous updates, NEPTUNE Machinery incorporates proven technology into its bottling plants, ensuring reliability and performance.

more capacity plant Optional

2000BPH Water bottling plant

Fully automatic process from manufacturing plastic bottles to packaging bottled water.

2000 Bottles per hour depend on 500ml bottle water(for 200ml to 2000ml bottle)

Labor inquire: 5 workers

Factory room inquire: 150+ square meter

Complete Plant FOB PRICE $65,010

4000BPH Water bottling plant

Fully automatic process from manufacturing plastic bottles to packaging bottled water.

2000 Bottles per hour depend on 500ml bottle water(for 200ml to 2000ml bottle)

Labor inquire: 5 workers

Factory room inquire: 150+ square meter

Complete Plant FOB PRICE $82,990

Introduce of water bottling facility

1. Bottle blowing machine

Through heating preform and blowing preform into plastic water bottle. All-inclusive bottle making system for making 200ml to 2 liter plastic water bottle.

2. Bottle water washing filling capping machine

Linear bottle water washing, filling and capping machine. 2000 Bottles per hour capacity depend on 500ml bottled water.

3. 1000LPH RO water purification

RO system will removed everything of raw water and producing pure water. The pure water is super pure TDS can reach 0-10.

4. Laser code dATE printer

It is use to mark produce and shelf life code on on curved surface of bottle water. More important, It do not cost any ink or else materials.

5. Bottle labeling machine

It need manual sleeve label on every pass bottled water, then bottle pass the shrink tunnel. PVC label face steam will tight on the bottle.

6. Bottle packing machine

Wrapping a lot bottle water in one bag with pe film, Then transfer the package go through shrink tunnel to shrinking the film and let it tighten these bottle water.

NEP-1000BPH bottling Plant : Equipment List

Please note that the specifications and capacities mentioned are based on the NEP-1000BPH model and may vary depending on the manufacturer’s specifications. It’s always advisable to check the specific details provided by the NEPTUNE MACHINERY.

| NO | NAME | QC |

| 1 | BM-S2 2 cavities BLOW MOLDING UNIT | 1 SET |

| 2 | ROTATING OVEN | 1 SET |

| 3 | High pressure air compressor(0.75M3/30KG); Brand Shangair | 1 SET |

| 4 | Air Dryer | 1 SET |

| 5 | Air Filter(1.0m3/min 30kg); Brand Hangzhou Tian cheng | 2 SET |

| 6 | Two cavities blow mold (200-2000ml) | 1SET |

| 7 | Two cavities blow mold (200-2000ml) | 1SET |

| 8 | Chiller for mold 3HP (Air cooling type) | 1SET |

| 9 | Spare part & High pressure Pipe | 1SET |

| 10 | TC-3.0 SUS304 PRE-TREATMENT All Stainless steel pipe | 1SET |

| 11 | Reverse Osmosis Unit (4PSC 4040 Membrane) All Stainless steel pipe | 1SET |

| 12 | UV-40W Ultraviolet sterilization assembly | 1SET |

| 13 | SOZ-3G Ozone Generator And Mixing System (Air source) | 1SET |

| 14 | 1000L 810*1800 SUS304 Pure Water Tank (Thickness 0.5mm) | 1SET |

| 15 | 1000L 810*1800 SUS304 Raw Water Tank (Thickness 0.5mm) | 1SET |

| 16 | Connecting pipe and else | 1SET |

| NO | NAME | QC |

| 17 | Extra PP Filter For Change | 6PSC |

| 18 | RO-1000(1000LPH) Spare part | 1SET |

| 19 | W-12 Auto Bottle Washer | 1SET |

| 20 | NF-12 Normal Pressure Filler | 1SET |

| 21 | SC-1 Screw Capper | 1SET |

| 22 | Conveyor belt, (With motor) | 6M |

| 23 | Load bottle table | 1SET |

| 24 | Finished bottle table (Spare) | 1SET |

| 25 | 12-12-1 Spare part | 1SET |

| 26 | STEAM SHRINKING TUNNEL | 1SET |

| 27 | STEAM GENERATOR | 1SET |

| 28 | Conveyor belt (With Motor) | 4M |

| 29 | Working Table | 1SET |

| 30 | PNEUMATIC SLEEVE WRAPPER | 1 SET |

| 31 | JET THERMAL SHRINK MACHINE | 1SET |

| 32 | 2.2KW AIR COMPRESSOR | 1SET |

| 33 | CP-30W Code Date Water Bottle Laser Printer | 1SET |

What Bottle Water Can This Water Bottling Plant Manufacturing?

It can bottling water and soda water without syrup. Like pure water, mineral water and spring water. It can bottling bottle water volume range from 100ml to 2000ml.

One bottling line can through change mold to producing different volume and shape bottle water. You can use one water bottling plant for making hundred different bottle water. But every kind of bottle mold cost $350 extra.

500 ml Purified water

555 ml Pure water

750 ml Soda water

1.25 L Soda Water

1.5 L Soda Water

1.5 L Mineral Water

Make it easy to open an bottle water plant in Africa

It is a very economic for first start. Its model is NEP-1000BPH. There are over thousand semiautomatic bottling line running still running in the world. It standing the market test. Most machine of the bottling line are automatic but connection is manual. It working steadily and reliable. It is easy to operate and maintain bottling line.

The complete bottling line just take 70square-200square meter production room. A lot bottle water factory start it at an normal building. Not need special find an factory room

Make your own Unique Bottled Water

A good manufacturer of water bottling plant must support bottle design, label design, layout design, warranty, installation and after sales. Manufacturer is experienced of a lot plant every year. Those basic support most should be free and easy support by manufacturer. And installation should be cheap and fast support by manufacture

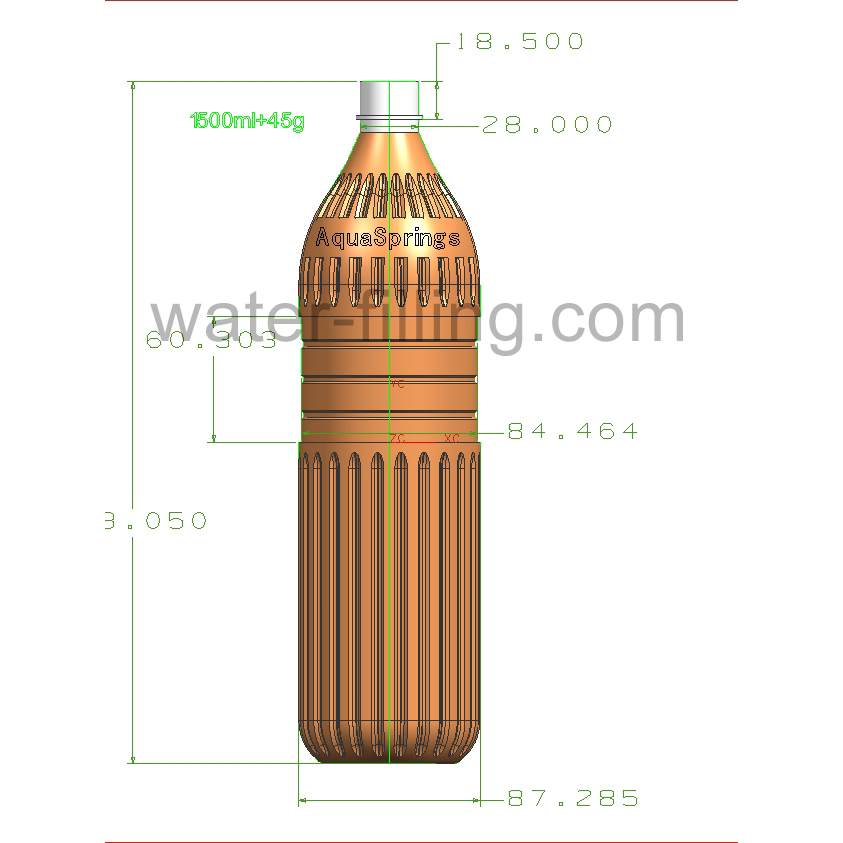

Make your own plastic bottle

NEP-1000 water bottling plant is small invest to start the bottled water business. But it still included the bottle blowing machine.

You can buy preform and blowing it into your unique plastic bottle in your factory.

Save the freight empty plastic bottle cost. What’s more, fast blowing container and finished filler will be better for bottled water quality.

Best quality mold

China best blow mold technology.

Make sure produce out plastic bottle best quality. Produce out mark clear and strong beauty plastic bottle.

Free Bottle Design, Professional And Beauty

Over 20years bottled water experienced. We can find any bottle design drawing mistake and at the drawing step avoid detour like actually bottle waddled.

We use the most professional scanning and design system, make sure the bottle design same with the final really bottle. Accurate without mistake.

Aim Best Quality Bottle Control

To produce out the best quality plastic bottle. It will been like by bottle water customer. Then lead good business to the bottled water factory.

How is the installation for water bottling plant?

In past 20years. We build an lot water bottling plant in Africa. Support engineer installation and training.

We can send both China and Africa engineer who have 10 years experienced for oversea installation.

How to do label design for bottle water?

NEPTUNE Machinery not only provides a reliable and efficient bottling plant with the NEP-1000, but they also offer professional bottled water label design services. Buyer just need offer basic information and idea picture. Then NEPTUNE will let designer do the professional water bottle label design. make sure your final bottled water beaty like an art. All this work is free. Here are some key aspects of their label design service:

- Professionalism:NEPTUNE Machinery’s design team is experienced and professional, ensuring that your bottled water label reflects a high level of quality and sophistication.

- Artistic Appeal:The goal is to make your bottled water label look like a piece of art. The design team pays attention to aesthetic details, ensuring that the final product is visually appealing and stands out in the market.

- Customization:The label design service is tailored to meet your specific needs and preferences. Customization allows your brand to have a unique identity in the competitive bottled water market.

- Free Service:NEPTUNE Machinery offers this label design service for free, which can be a significant cost-saving benefit for entrepreneurs starting their bottled water business.

- Attention to Detail:The design team pays close attention to every detail of the label, including color schemes, typography, imagery, and branding elements. This meticulous approach ensures a polished and professional appearance.

- Brand Identity:The label design aims to enhance your brand identity and create a positive association with your bottled water. Consistency in branding helps in building trust among consumers.

- Collaborative Process:NEPTUNE Machinery involves you in the design process, allowing for collaboration and feedback. This ensures that the final design aligns with your vision for the brand

By offering a professional label design service at no additional cost, NEPTUNE Machinery aims to support entrepreneurs in creating a strong and marketable brand presence for their bottled water products.

analysis of The nep-1000 wATER BOTTLING PLANT

Every water bottling line has its advantages and disadvantages. We just need choice the one advantages are what we love while its disadvantage are what we can accept or don’t care about.

Advantage

- Cheapest NEP-1000 Bottling line for first start bottle water business.

- Small production room inquiry complete bottling line just take 70square-150square meter production room. A lot bottle water factory start it at an normal building. Not need special find an factory room.

Dis-Advantage

- A lot labor inquiry. About 11 workers.

- Speed is slow. Just 1000 bottles per hour. 24hours per day just 24000 bottles production depend on 500ml bottle water.

- Worker hand touch the outside of the plastic bottle when conveyor bottle to next process. It is not very good for bottled water Contactless production

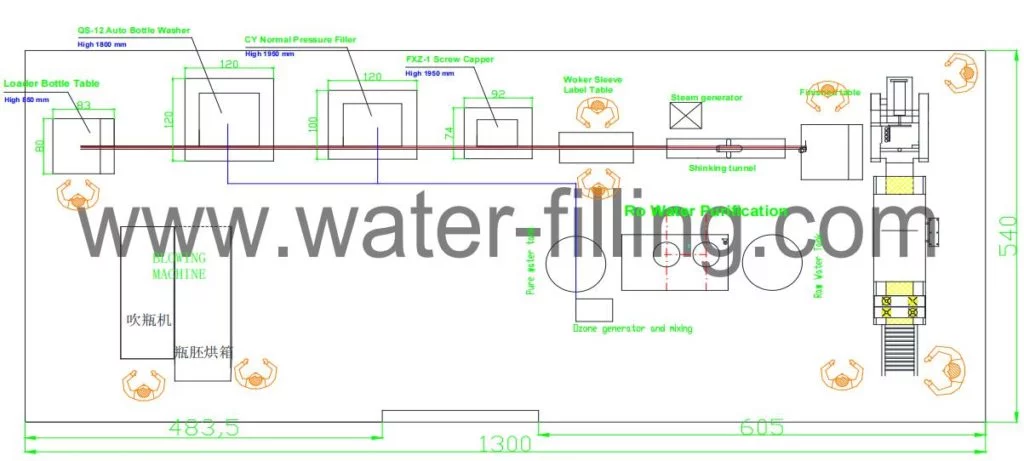

How to do layout for water bottling plant?

Complete nep-1000bph water bottling plant only need an 70 square meter production factory. Other room if have then can use for office and storage room. Send us your factory drawing and we will drawing the whole line layout for you. Here are some considerations and advantages:

- Space Efficiency:The compact design of the NEP-1000BPH allows for efficient use of space, making it suitable for smaller production facilities. A smaller space requirement often translates to lower overhead costs for rent and utilities, contributing to a more cost-effective operation.

- Convenient Location:Placing the facility on the first floor, close to the road, facilitates easy transportation of finished bottled water to the market, reducing logistical challenges.

- Flexibility:With the right layout planning, you can efficiently organize the production line, including the washing, filling, and capping processes, within the limited space.

- Market Accessibility:Proximity to the road enhances accessibility for delivery trucks, streamlining the distribution process and ensuring a timely supply of bottled water to the market.

- Local Regulations:Check local regulations and zoning requirements to ensure compliance with any specific rules related to water bottling plants in your area.

- Infrastructure Considerations:Ensure that the facility has the necessary infrastructure, such as water and power supply, to support the bottling plant’s operation.