High efficiency 1500bph semiautomatic PET bottle blowing machine suitable to making and produce different shape 200ml to 2000ml pet plastic bottle.Model: BM-S4

FOB PRICE $ 11650

What this price included?

| NO | NAME | UNIT FOB PRICE | QC | TOTAL FOB PRICE |

| 1 | BM-S2 2CAVITY BLOW MOLDING UNIT | USD 2,000.00 | 1 SET | USD 2,000.00 |

| 2 | BM-S2 2CAVITY BLOW MOLDING UNIT | USD 2,000.00 | 1 SET | USD 2,000.00 |

| 3 | ROTATING OVEN | USD 1,800.00 | 1 SET | USD 1,800.00 |

| 4 | High pressure air compressor(1.2M3/min 30KG); Brand Shangair | USD 2,050.00 | 1 SET | USD 2,050.00 |

| 5 | Air Dryer | USD 600.00 | 1 SET | USD 600.00 |

| 6 | Air Filter(1.0m3/min 30kg); Brand Hangzhou Tiancheng | USD 150.00 | 2 SET | USD 300.00 |

| 7 | Two cavities blow mold (200-2000ml) | USD 400.00 | 2SET | USD 800.00 |

| 8 | Two cavities blow mold (200-2000ml) | USD 400.00 | 2SET | USD 800.00 |

| 9 | Mold-Chiller 3HP Air Type | USD 1,300.00 | 1 SET | USD 1,300.00 |

| 10 | Spare part & High pressure Pipe | FREE | 1SET | FREE |

high quality, high efficiency

Applications: Ideal for beverage manufacturers, polyester bottle producers, serving as perfect equipment for water bottle production.

NEPTUNE PET Bottle Blowing Machine for efficient, versatile, and cost-effective plastic pet bottle production.

Key Features:

- Capacity of Production: Produces 1500 bottles/hour (500ml), running 24/7 for a daily output of 36,000 bottles.

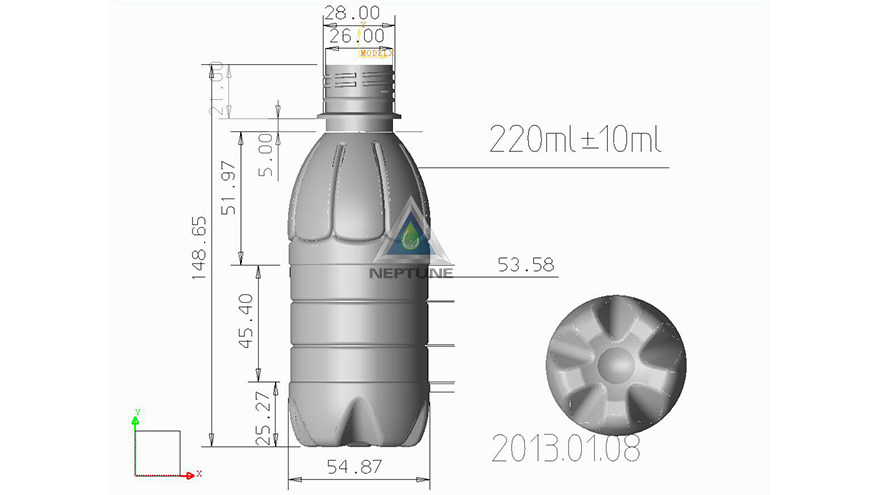

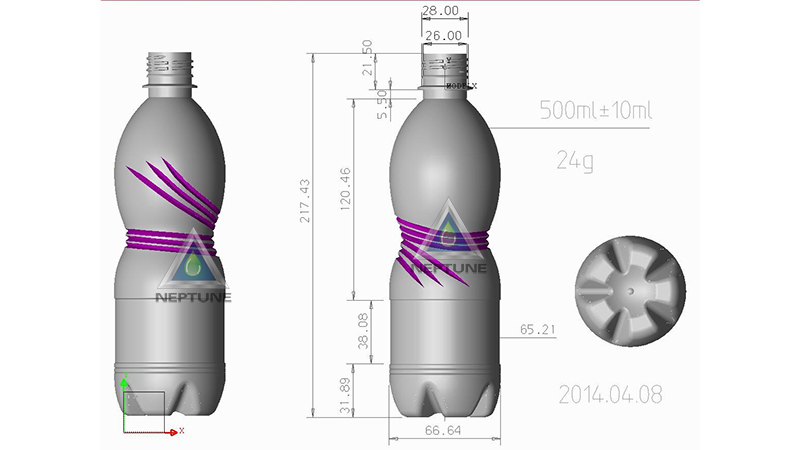

- Versatile Bottle Shapes: Suitable for various PET tube-shaped bottles used in mineral water, carbonated drinks, sauces, juices, medicines, cosmetics, and oils.

- Even Heating: Adopts revolving infrared pre-heater for extremely uniform heating of PET preforms.

- Operation Modes: Can be operated in step-by-step.

- Cost-Effective: Small size, low cost, easy and safe operation.

Blower Technique Parameter

| ITEM | DETAIL | |

| Container | Product material | PET |

| Volume | 0.1L-2L | |

| Theoretical output | 1500PCS/H | |

| Preform length | 15mm-350mm | |

| Preform inner diameter | φ5mm-38mm | |

| Moulding | Max. mould plate Dimension (L x W) | 350x380mm |

| Max. mould thickness | 180mm | |

| Clamping force | 45KN | |

| Mould opening stroke | 160mm | |

| Machine size and weight | Main machine (L x W x H) | 160x60x161cm |

| Main machine weight | 500Kg | |

| Heater (L x W x H) | 187x63x145cm | |

| Heater weight | 250Kg | |

| Power | 17.5kw | |

INTRODUCE

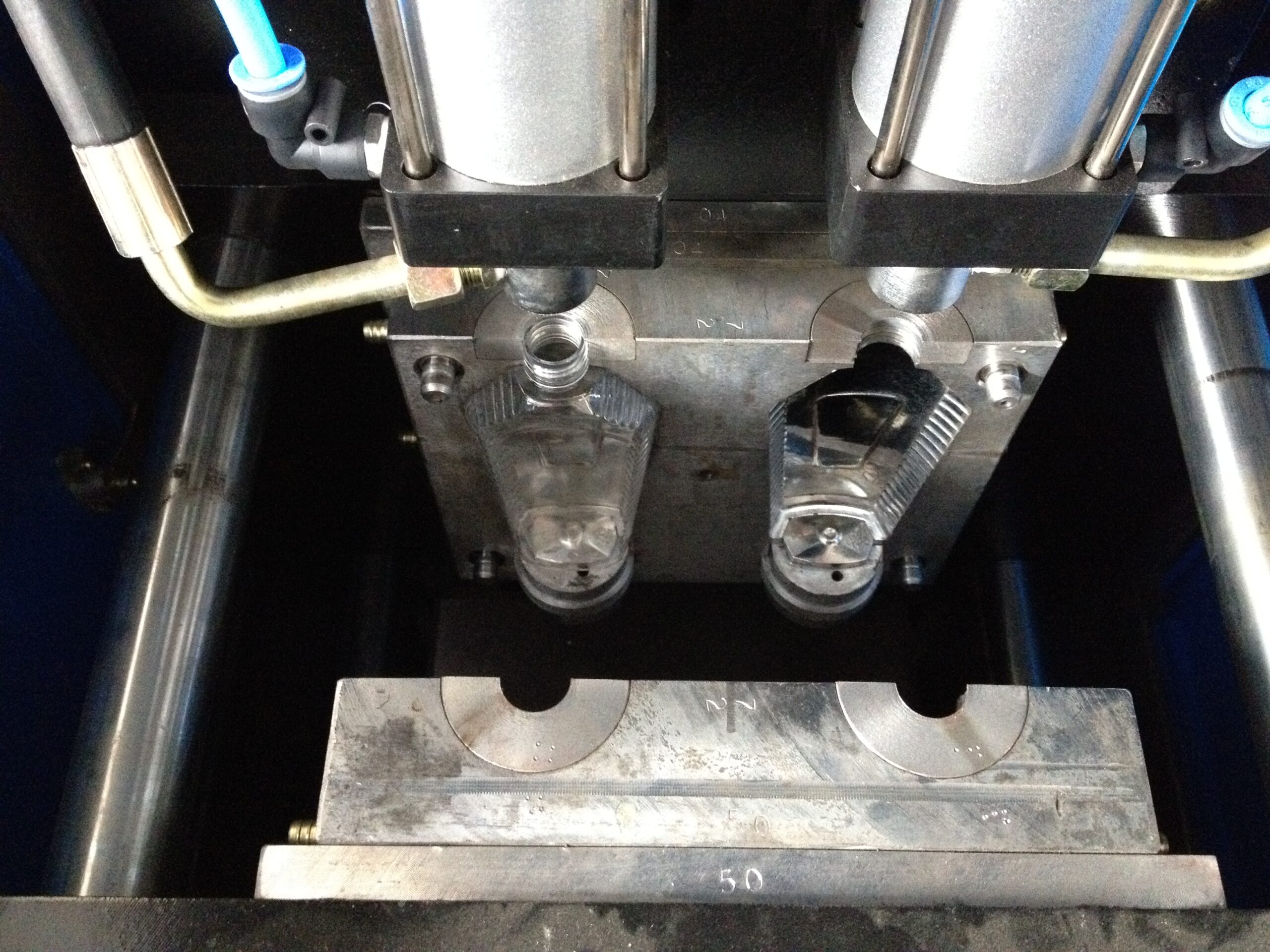

2CAVITY BLOW MOLDING*2SET

Technical parameter:

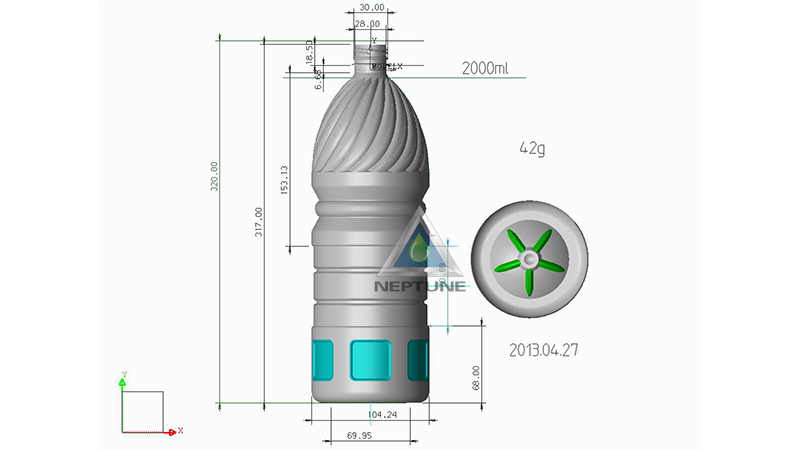

- Volume of bottle: 200- 2000ml

- Production Capacity: 800pieces per hour

- Heating Power rate: rated, 14 Kw, working power rate: 7.2 Kw.

- Air source pressure: 2.5mpa

- Max. Mould Size: 20×35×38cm

- Max. Mould Moving Size; 17 cm

- Distance between the centers of two bottles: 9-20cm

- Max. stretching length:35cm

- Weight: 650 Kg

- Size: 160×60×161cm

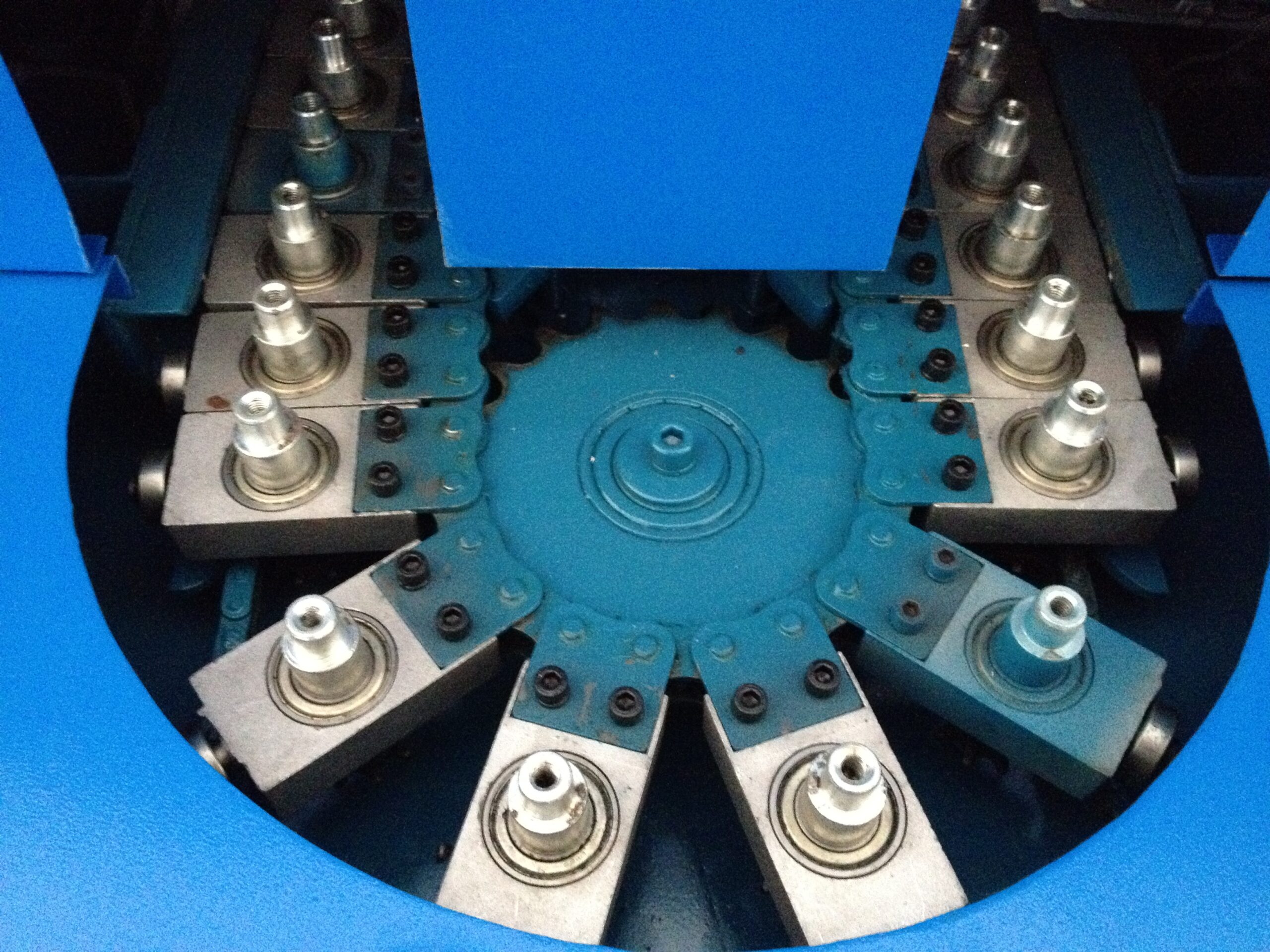

ROTATING OVEN

Technical parameter

- Total power:17.5kw

- Using power:7.2kw

- Heating tube power:600w*28=16.8kw

- Motor power:0.55kw

- Pre-form support: 72pcs

- Pre-form heating range: Applicable for various kinds of pre-forms

- Overall dimension:18765145cm

- Weight:250kg

BLOWER

The machine adopts revolving infrared pre-heater. It ensures extremely even heating for PET preforms.

The machine uses mechanical-double-arm mould clamping which ensure the mould be closed tightly even in high pressure.

TUNNEL

Rotary infrared heater heats pre-forms by moving pre-forms to pass through infrared heating area twice. by this method, heating is uniform and of high efficiency,

Infrared heating area is strictly divided into seven zones of A,B,C,D,E,F,G from up to down, Temperature requirements for all parts of pre-form are satisfied by controlling temperature of corresponding zones.

The feeding of pre-form for heating and taking away of heated pre-form shall be conducted manually which is simple and convenient.

Is the BM-S4 Blower suitable for different bottle shapes and sizes?

The NEPTUNE 4-Cavity 1500BPH Semiautomatic PET Bottle Blowing Machine is suitable for producing differently shaped bottles of PET material. It is designed to accommodate various bottle shapes and sizes, making it versatile for applications such as mineral water, carbonated drinks, candy sauce, juice, medicine, cosmetics, and oil bottles.

Production 1500 bottles per hour: depend on 220ml bottle

Production 1500 bottles per hour: depend on 500ml bottle

Production 800 bottles per hour: depend on 2000ml bottle