Bottle Sleeve Labeling Machine utilizes PVC labels that naturally shrink in high-temperature steam, ensuring a secure and sleek fit on bottled water, enhancing the overall appearance.

FOB PRICE $12300

What this price of Complete sleeve labeling machine included:

- Auto sleever / 1set

- Shrink Tunnel/ 1set

- Steam generator /1set

- Motor/1set

- 7meter long conveyor

It is an highly automated bottled water PVC sleeve labeling machine. It contains two parts. First, auto sleeve label on every pass bottled water on the conveyor belt. Then the bottled water with label conveyor pass the hot-gas thrink tunnel.

It can sleeve different kind of bottle types. for example: round bottles, square bottles, flat bottles, curved bottles and cup-shaped bottles, etc.

- The label rack can easy adjust which fit an lot label.

- The sleeve labeling machine install is simple. Easy for both square and round bottle.

- It is use automatic controlling feeding system. It can level-off the sleeve label film materials and adjust strain simultaneity.

- It is use unique design knife plate. Do not need change knife and base if the label small different size. Also it is easy to change knife and base if need.

- It is use label location system which can promote and demote in-phase adjust location according to specific bottle type requirement.

- It is use high-sensitivity photoelectric which can make sure cutting label high precision.

- It is use advanced man-computer Interface auto controlling technology.

Parameter

| Capacity of production | 6000 bottles per hour |

| Materials | PVC label |

| Applicable Product | Bottled Water, Bottled Juice, Bottled Coke |

| Bottle Volume | 200ml-3000ml |

| Sleever Power | 3KW |

| Shrinking Power | 15kw |

| Voltage | Setting according customer inquiry |

| Main machine dimension | 2200L×1100Wx2000H |

| Applicable diameter of bottle body: | 28mm~125mm |

| Applicable thickness of label | 0.03mm~0.13mm |

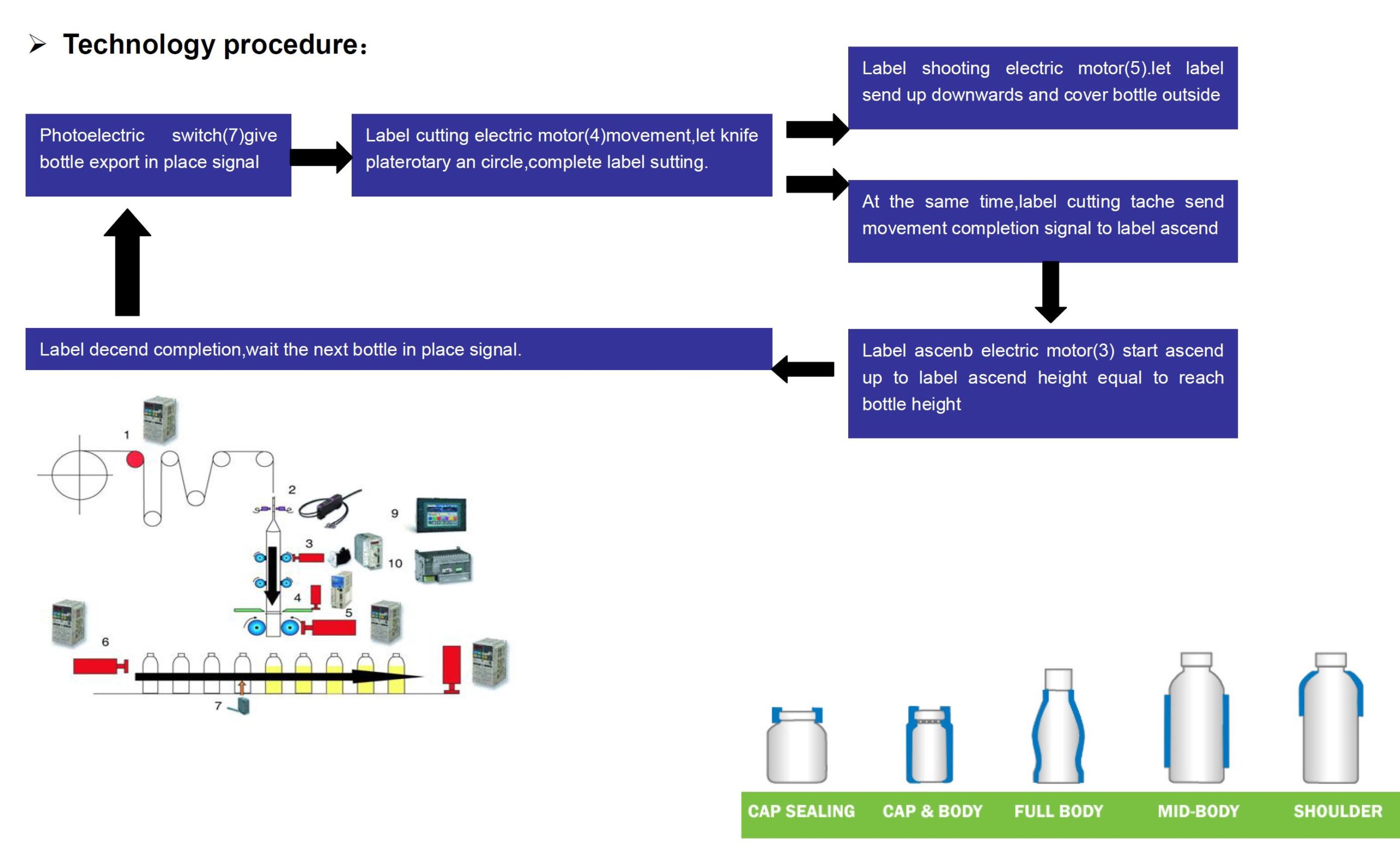

working process

Sleeve Labeling Machine operates by conveying all bottled water via a belt. The machine utilizes a knife plate to automatically cut a label and apply it as a sleeve onto the bottle. A high-sensitivity photoelectric system reads the passage of each bottle. Although each bottle receives a sleeve label during this process, the label is not yet tightly affixed to the bottle.

Subsequently, the bottles with PVC labels move through a shrink tunnel that emits high-temperature steam. The steam serves to heat the PVC label, causing it to shrink and tightly adhere to the bottle. This final step ensures that the label becomes securely fitted to the bottle, providing a sleek and well-finished appearance.

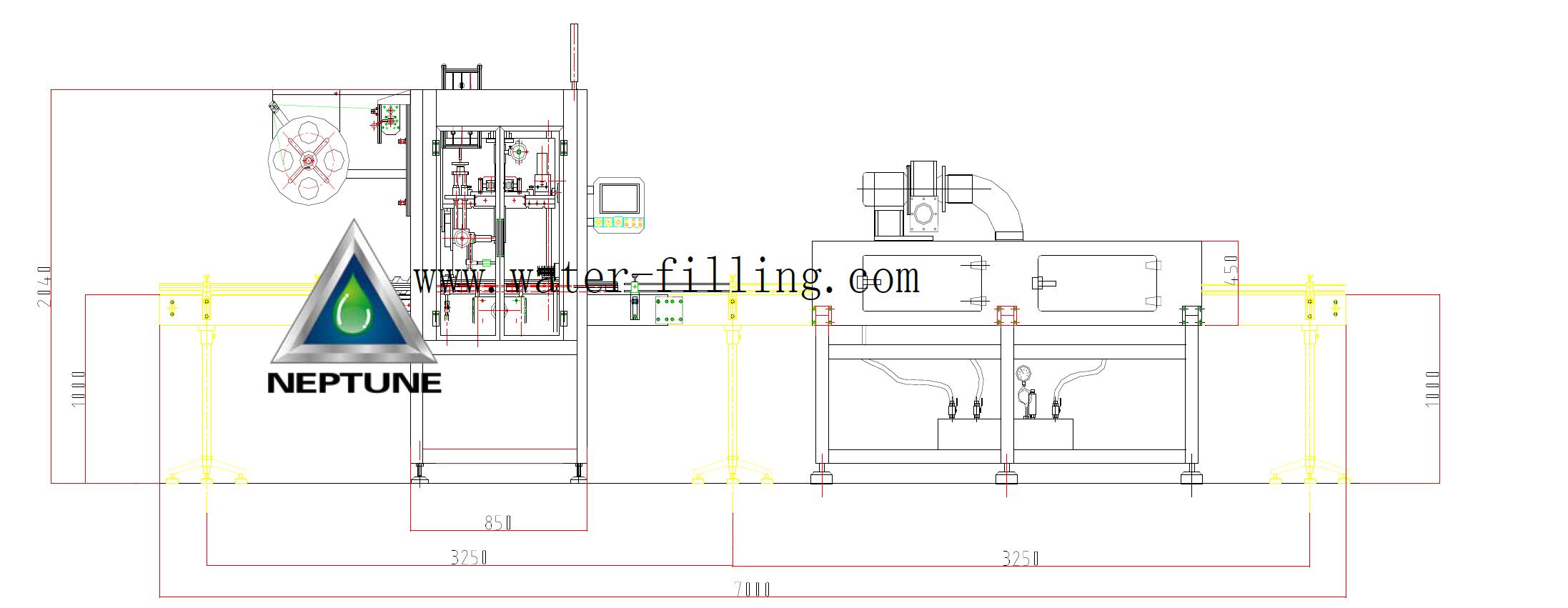

Layout

The layout of the sleeve labeling machine involves a conveyor belt system that spans a total length of 7 meters, extending from the beginning to the end of the production line.

The conveyor belt runs through the sleever machine and the shrink tunnel. It is powered by a motor, which drives the movement of the conveyor belt.

This setup ensures a seamless and efficient process as bottles or containers move through the sleeve labeling machine and subsequently pass through the shrink tunnel, where the PVC labels tightly adhere to the bottles through the application of hot gas.

The motor-driven conveyor system plays a key role in facilitating the entire sleeve labeling process.

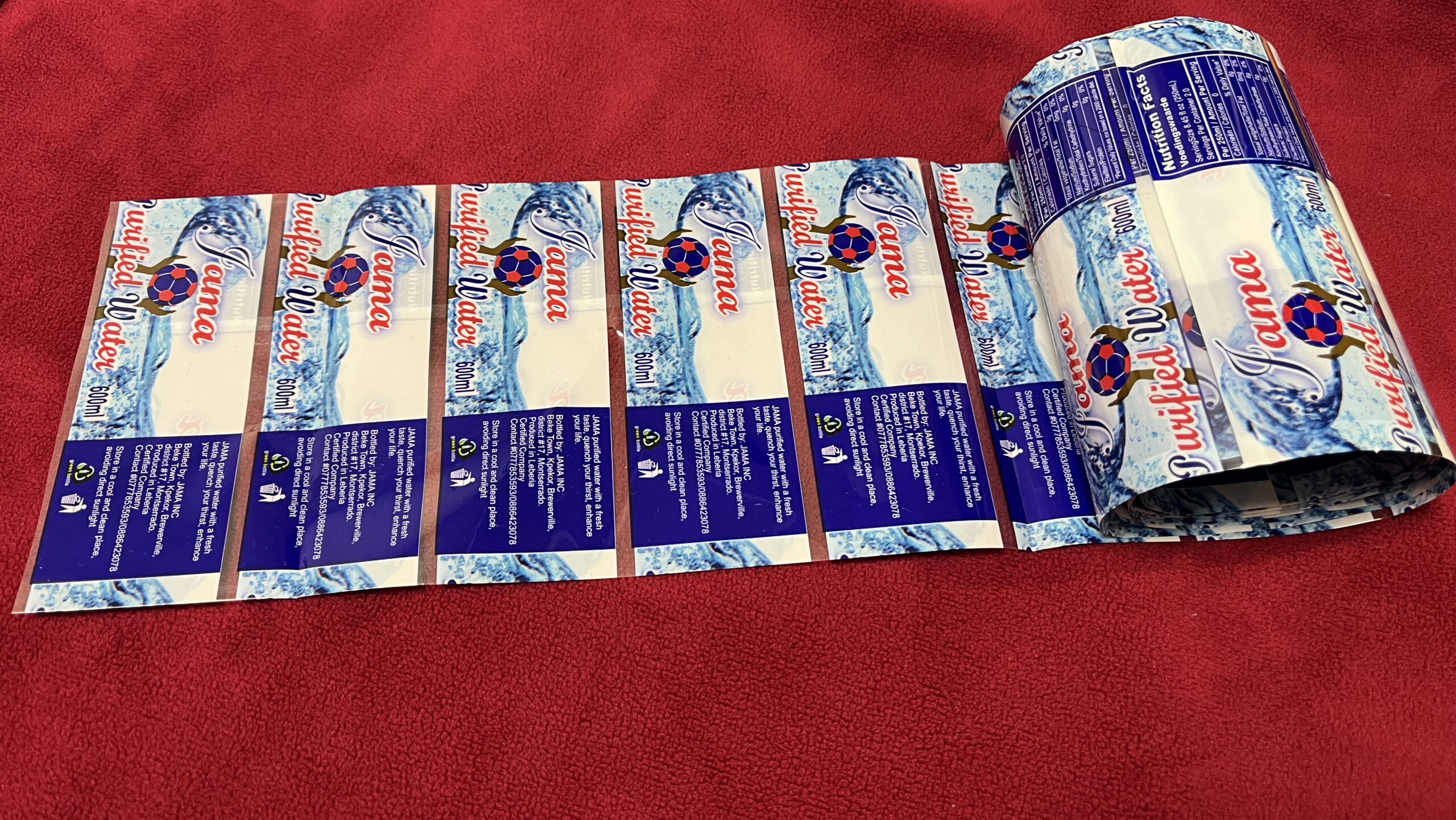

Materials: PVC label

500ml bottle label cost $0.004/piece

The automatic sleeve labeling machine is made use of PVC sleeve shrink label as materials. The label is continued one roll. And the sleeve labeling machine will hold it and continued sending the label to th e position and cutting, Then sleeve labe on every pass bottled water. Then the bottled water go through shrink tunnel face the hot steam. The steam will shrink the PVC label to make it got tight on the body of the bottled water.

1500ml bottle label cost $0.008/piece

The sleeve label is the cheapest way as labeling materials for bottled water. It just cost 20-30% of the sticker label, If long time production. One year can save a large number of machine. And the sleve label do not have any glue on the bottled water, So that it will give customer a good impression.

Sleeve Label VS Sticker Label

PVC shrink label

500ml PVC shrink label usually cost USD 0.004. Its mainly cost at printing. The plastic film cost less

Sticker label

500ml Sticker label cost USD 0.02 . Its over 5times cost than PVC shrink label.

1psc 500ml label will save 0.02-0.004=0.016 dollar, if every year cost 10million piece label, so that an factory can save:

10million label*0.016dollar=160000dollar

An nep-2000bph water filling line plant 1years can produce 10million bottled water

Why they are a lot company still use sticker label,first they are old famous company which customer custom it. Second sticker label can do some special design which some special beauty bottle water company like it. They do not care about too much raw materials cost, and their bottle water average cost high.

why choice sleeve rather than sticker label?

The choice of sleeve labeling over sticker labeling is influenced by several factors, with cost being a significant consideration. While sticker labeling has been popular for the past two decades, many new bottled water companies are opting for sleeve labeling. One key factor in this decision is the raw materials cost.

Sleeve labeling materials cost only 20% of what is required for sticker labels. Additionally, sleeve labeling is considered more aesthetically pleasing, and the labels do not easily detach. The sleek and modern appearance of shrink labeling, without the presence of traditional stickers, has become a preferred choice for many new bottled water companies. This cost-effective and visually appealing solution is gaining popularity in the industry.