What equipment is needed for a water bottling plant?

Setting up a water bottling plant requires several key pieces of equipment to ensure efficient and hygienic production. Here is a list of essential equipment for water bottling plant:

Water Fillng Machine

An automatic or semi-automatic water bottling machine for filling and sealing water bottles. This can be a gravity filling machine, piston filling machine, or similar.

3/5Gallon Bottled Water Filling Machine

It is an water filling machine for 3gallon 4gallon 5gallon & 6gallon plastic bottle water.

0.2-2Liter Bottled Water Filling Machine

3-in-1 monoblock water filling machine for small bottle 200ml-2000ml.

3-10Liter Bottle Water Filling Machine

It is 3liter to 10liter straght line type included washing filling and capping part.

Sachet Water Filling Machine

Sachet filling machine for filler and sealing bag pure water, Produce bagged pure water.

Bottled Water Package Machinery

An automatic or semi-automatic labeling machine for applying labels to the bottles. Wrap package machine helps in providing a protective layer and branding to the bottled water. Date printer machine printing produce date on your bottle water.

Automatic Sleeve Labeling Machine

It will sleeve label on bottle water and heating shrink the label , so that tight the label on bottle water

Wrap Film Shrink Packing Machine

It will wrap film on 12/24psc bottle water and heating shrinking the film.

Bottle Date Ink Jet Printer

Printing produce date on every pass bottle water of an water bottling line.

Semiautomatic Wrap Film Package Machine

Wrap film on a lot bottled water and got tight all bottled water after go through steam tunnel.

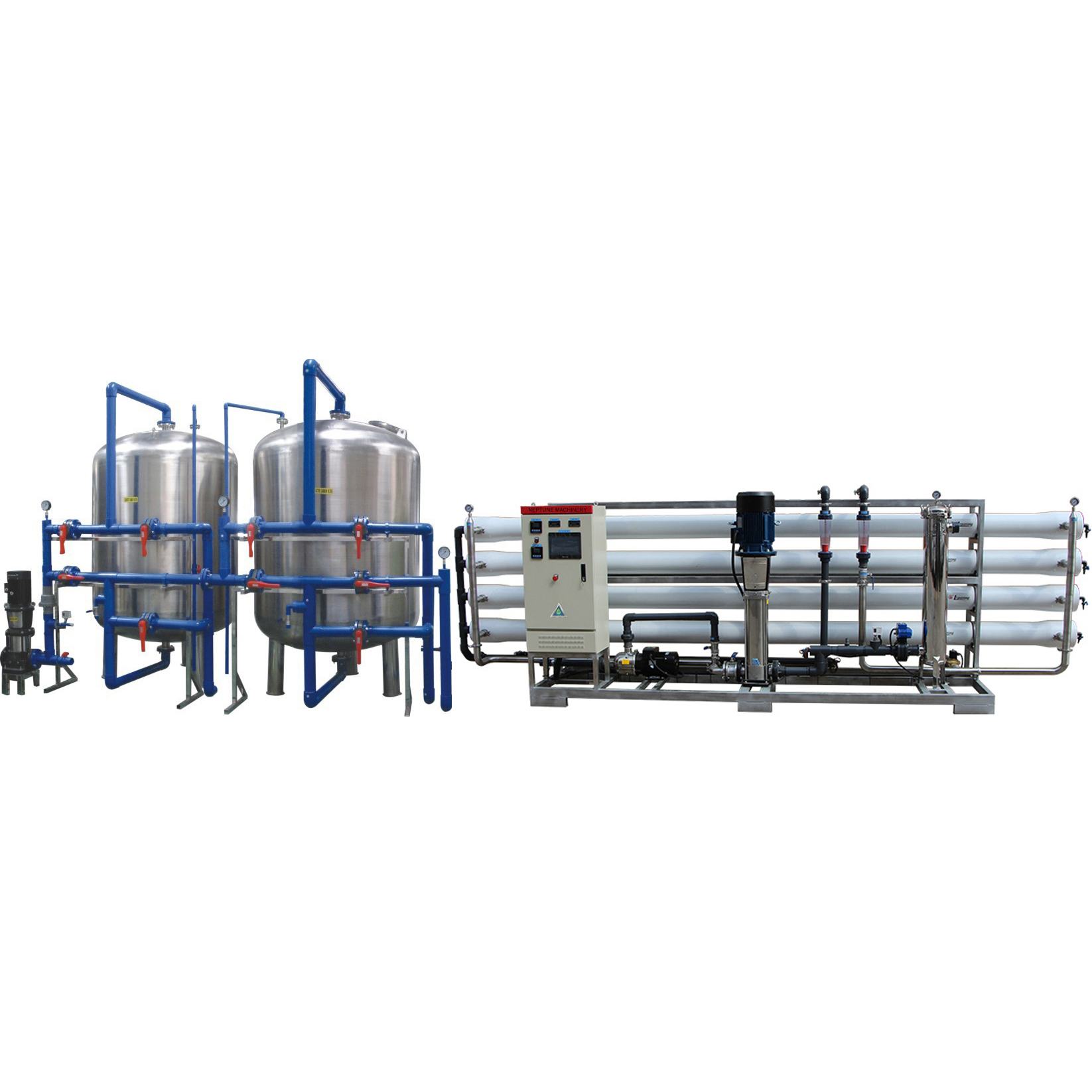

RO Water purification Machine

Reverse Osmosis (RO) water purification systems to ensure the product pure water meets quality standards.

Automatic bottle making machine

Automatic bottle making machine to make plastic pet water bottle through heating and blowing preform.

4000BPH Auto Blow Moling Machine

Hot sales automatic blow molding machine. It have 4cavity and speed is 4000psc per hour depend on 500ml bottle.

5L Auto Blow Molding Macine

One cavity 2liter to 5liter automatic blow molding machine is suitable for producing PET plastic container and bottles.

3-5Gallon Bottle Automatic Blow Molding Machine

It is an automatic 3gallon to 5gallon pet bottle blow molding machine. It can produce 3gallon to 5gallon reuse pet bottle.

2000BPH Automatic Bottle Blow Molding Machine

2000BPH Automatic PET Plastic Bottle Blow Molding Machine are suitable for producing plastic bottles in all shapes.

Semiautomatic bottle blow molding machine

Semiautomatic bottle blow molding machine help you produce your own unique plastic pet water bottle.

5Gallon PET Bottle Blow Machine

Capacity is 60Bottles per hour. Not only can produce reuse 5gallon bottle, But also can produce once use 20liter bottle.

Cheapest Bottle Blow Molding Machine

It is the smallest production and cheapest blow molding machine, Production is 800bottles per hour. Budget not over 8000dollar.

5-10L Bottle Blow Molding Machine

It mainly use to produce 5-10liter plastic bottle. 5-10liter pet bottle not only use for water, but also use to filler oil.

2500BPH Bottle Blow Molding Machine

It is the fastest semiautomatic blow molding machine, Once produce 4psc bottle and automatic fall down.

It’s important to note that the specific equipment needed can vary based on the scale of production, the type of bottled water (still, sparkling, flavored), and the local regulations. At NEPTUNE MACHINERY, Consulting with industry experts or a professional in the water bottling business can also provide valuable insights.