What is carbon drink production line?

It is an completely production line which use to produce bottled carbon drink. Like bottled coke, bottled sprite and bottled sparkling water. It mixer beverage syrup and carbon at 3 degree temperature.

Carbonated drink filling production and bottling line is mainly suitable for filling carbon drink which have gas (Carbon dioxide) .

Carbonated drink filling production and bottling line is mainly suitable for bottling and packing of round or square polyester carbon drink bottles. According to the demands of different specifications of users, it is only changed a little in design to meet the user’s demands.

Carbonated beverages (soda) is filled with carbon dioxide gas in the beverage. The main components of carbonated beverages include: Carbonated water, citric acid and other acidic substances, sugar, spices, and some contain caffeine, artificial colors and so on.

Carbonated included : Coke , Sprite , soft drinks.

Why choice neptune carbon drink production line?

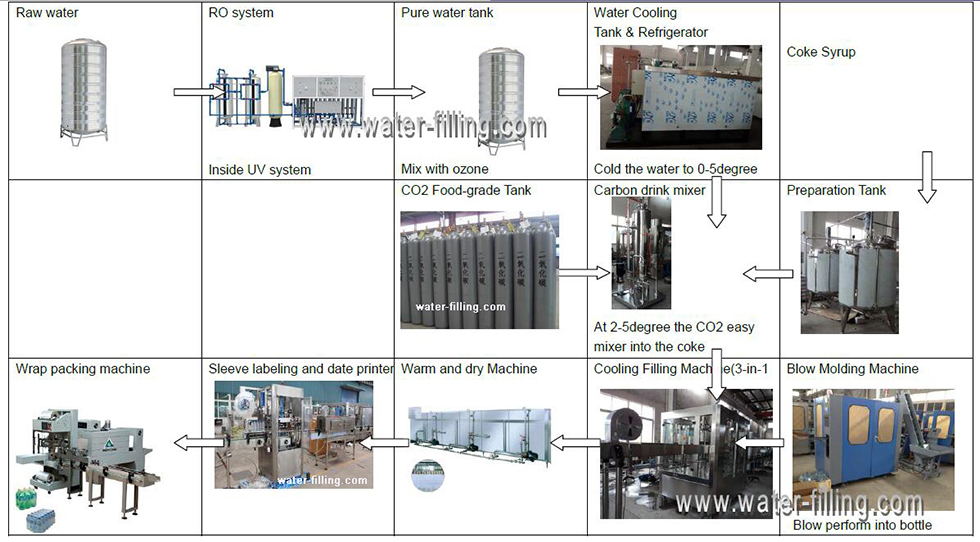

Our carbonated drink production line includes the water treatment unit, blow molding machine, chilled water tank, beverage mixer, syrup chiller, syrup filter, mixing tank, sugar melting pot, air conveying system, three-in-one balanced pressure filling system, sterilizing machine, auto conveying system, air purification system, OPP/PVC labeling machine, wrap shrinking packing machine and so on.

We directly supply the carbon drink syrup like caco and different brand carbon syrup. Original mixer well for customer or copy famous brand. Customer can save the sugar pot machine and mixer machine. And got professional and best taste syrup. Only need mix syrup, water and carbon in factory and then fast filler the carbon drink in the bottled.

Buy cola syrup, sparking syrup and gas water syrup from neptune.

syrup: water = 1:50

RO Water Purification

RO system removes all hydronium, organic substance, colloid, bacteria of the raw water. So it can produce the most purified water. You can use reiver water , underground water and city water as resource water. The final pure water standard TDS is 2-10. For example, If one kind of water composed entirely of water molecules, its TDS is 0. Most market pure bottle water TDS is 2-50. It supply pure water for mixer and produce CO2 drink, the carbon drink will have the best testing feeling.

Carbonated drinks (soda) products is under certain conditions filled with carbon dioxide gas including drinks, carbonated drinks, sports drinks and other inflatable specific varieties, not including the production of carbon dioxide gas from its fermentation beverage. The content of carbon dioxide in the finished product (at 20 DEG C) is not less than 2 times. Carbonated drinks are the main ingredients for sugar, pigment, sweeteners, sour agents, spices and carbonated water, etc., generally do not contain vitamins, mineral.

Carbonated drinks (soda) can be divided into fruit type, fruit type, cola type, low calorie, other type, such as: Sprite, Fanta, Coca Cola, 7up mirinda. The fruit juice carbonated beverage that contains more than 2.5% natural fruit juice and carbonated drinks; fruit refers to the spices as the main fragrance agent, fruit juice content of less than 2.5%; carbonated beverage that contains Cola fruit, lemon, white wine, caramel; other carbonated drinks: carbonated drinks, milk egg white ice cream soda.

Carbon Drink Mixer

Carbon drink mixer is the most important equipment in the carbon drink bottling line. One kind of drink can not be Carbon drink without CO2. So, mixer CO2 with water and syrup is the key process. Carbon drink mixer can good mixer cooling water with syrup and CO2. And produce out carbonated drink.

Carbon drink balance washing filling capping machine

Carbon drink Washing-Filling-Capping machine is an ideal carbonated drink filling production equipment in the country. It is mainly suitable for filling and capping of round or square polyester bottles. According to the demands of different specifications of users, it is only changed a little in design to meet the user’s demands.

Pressure carbon drink filling machine for filling in is higher than that under atmospheric pressure, can also be divided into two types: one is the liquid storage cylinder pressure and equal pressure bottle, by gravity into the bottle and liquid filling, called pressure filling is another; liquid storage cylinder pressure is higher than the pressure of the bottle of liquid by the pressure into the bottle, high-speed production line adopt this method. Pressure filling machine is suitable for filling liquid containing gas, such as beer, soda, champagne and so on

List of carbon coke production line

Balance Beverage Filling Machine

Warm the carbonated bottle coke Machine

Coke drink Syrup mixer system

Clean inside of the pipe machine

Mixer carbon with coke syrup machine

How does carbon drink filling production work?

Coco cola sell cola syrup to every branch. And every branch factory mix syrup with water and gas in locally. Then every branch supply coco cola bottled to market. We follow the coco cola way to design machine. We design the whole line from materials advantage. Contact neptune and got the different syrup cost and whole carbon drink bottling line.

No need. You can buy concentrate syrup which included everything. You can buy the syrup from local or from us. It is cheap. 1liter can use to produce 50liter product coka.