The specific packaging materials needed for a water bottling company will depend on the type of bottles and labels being used, as well as the type of caps or closures being used to seal the bottles. Some common packaging materials for bottled water include:

1. PET preform

| 14gram preform | 350ml bottle |

| 18gram preform | 500ml bottle |

| 20gram preform | 555ml bottle |

| 25gram preform | 600ml bottle |

| 28gram preform | 750ml bottle |

| 32gram preform | 1250ml bottle |

| 36gram preform | 1500ml bottle |

PET (polyethylene terephthalate) preforms are small, tube-shaped pieces of plastic that are used to create PET bottles. PET is a type of plastic that is commonly used for packaging food and beverage products, including bottled water.

PET preforms are made by injecting molten PET plastic into a mold to create the desired shape. They are then cooled and ejected from the mold. PET preforms are typically made in a variety of sizes and shapes to accommodate different types of bottles and containers.

Once the PET preforms are created, they can be blown into bottles using a process called blow molding. During this process, the preform is placed into a mold and hot air is blown into it, expanding the preform to fit the shape of the mold. The preform is then cooled to set the shape of the bottle.

PET preforms are a popular choice for bottled water packaging because they are lightweight, strong, and resistant to cracking and breaking. They are also relatively inexpensive to produce and can be recycled.

2. Screw Water-cap

A screw water cap is a type of closure or seal used to close the opening of a water bottle. Screw water caps are designed to prevent contamination of the water and maintain the quality of the product.

Water caps are an important component of bottled water packaging, as they help to protect the quality and purity of the water. They also help to prevent leaks and spills and make it easier to transport the bottled water. Water caps should be made of materials that are safe and non-toxic, and they should be easy to open and close.

Water cap price usually $0.007/piece

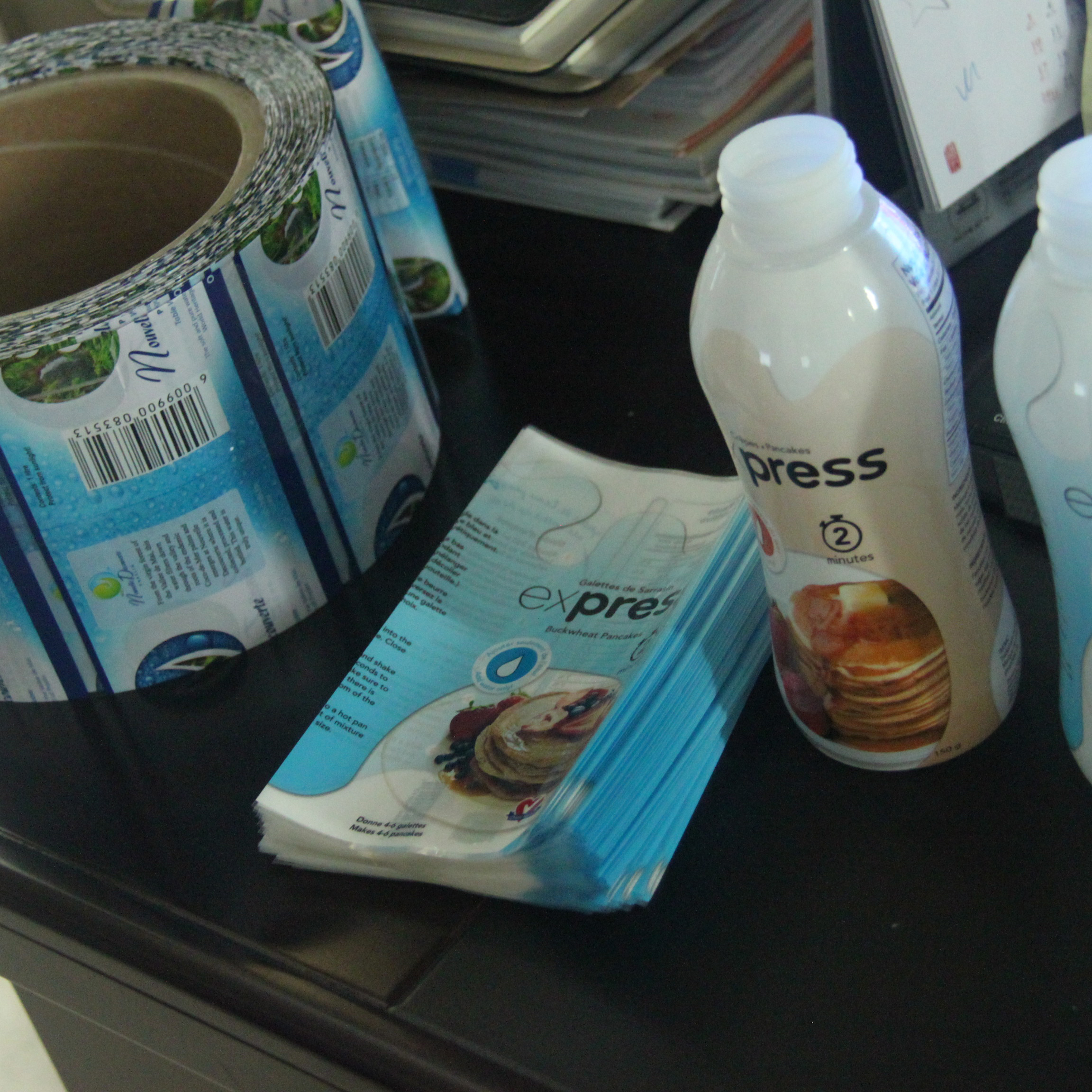

3. Sleeve Label

A sleeve label is a type of label that is designed to fit around the circumference of a container or bottle, covering part or all of the surface area. Sleeve labels are often used for packaging food and beverage products, including bottled water.

Sleeve labels have several advantages over traditional labels that are affixed to the front or back of a container. For example, they provide a larger surface area for printing information, such as brand names, logos, and product descriptions, and can be used to give a container a more premium or upscale appearance. They can also help to protect the container from damage and improve the overall appearance of the product on the shelf.

4. Wrapping film

Wrapping film is a type of plastic film that is used to wrap or cover a variety of bottles. Wrapping film is typically made of polyethylene or polypropylene and is available in a range of thicknesses and sizes.

Wrapping film can be used to protect products from damage, moisture, and contamination during storage, transportation, and handling. It is commonly used to wrap products on pallets or in boxes to keep them secure and organized.

In the food and beverage industry, wrapping film is often used to wrap and protect items such as bottled water, dairy products, and meats.

Wrapping film can be applied to products manually or using a wrapping machine. It is typically stretched and secured around the product using heat, pressure, or adhesives. Wrapping film can be recycled, but it should be disposed of properly to avoid litter and pollution.

In addition to these materials, you may also need packaging equipment such as filling machines, capping machines, labeling machines, and packaging equipment to package the bottled water. You may also need storage and transportation materials such as pallets and boxes to store and transport the bottled water.