Setting up a water bottling factory or start bottle water business in Mauritius involves several key steps. Here is a comprehensive guide to help you navigate the process:

1. Market Research and Business Plan:

- Conduct thorough market research to understand the demand for bottled water in Mauritius. Analyze the competitive landscape and identify your target market.

- Develop a detailed business plan outlining your business goals, target audience, marketing strategy, and financial projections.

- You can find an agent or supermarket, signature contract for supply bottle water for them. Then start build bottle water factory.

2. Legal and Regulatory Compliance:

- Familiarize yourself with the regulatory requirements for establishing a water bottling factory in Mauritius. Obtain necessary permits and approvals from relevant authorities.

3. Location and Infrastructure:

- Choose a suitable location for your factory, considering factors such as proximity to water sources, transportation access, and utility services.

- Set up the necessary infrastructure, including production facilities, storage areas, and administrative offices.

4. Water Source :

Identify a reliable and clean water source. Conduct water quality tests to ensure it meets safety and regulatory standards.

5. machinery needed to start a water bottling factory:

Purchase the water bottling equipment that includes water purificationn machine, 3in1 water bottling machine, bottle making machine, labeling machine and wrap package machines.

Ensure the equipment meets industry standards and has the capacity to handle your projected production volume.

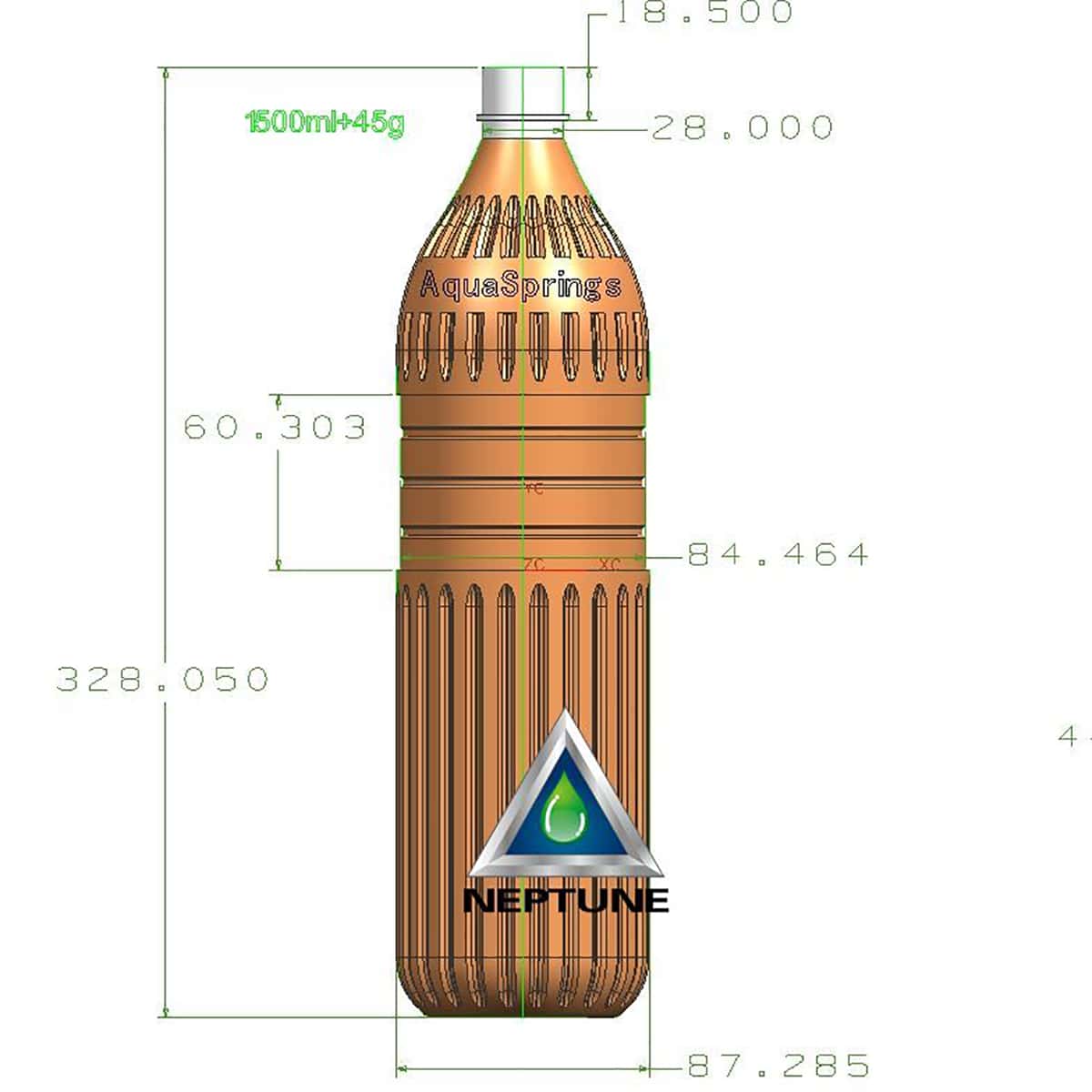

6. water bottle design

Designing a water bottle involves considering aesthetics and functionality. Choose a shape that aligns with the brand, pick materials for durability and sustainability, and select a color palette that reflects the brand identity. Ensure clear typography on labels for crucial information. Incorporate user-friendly features and prioritize sustainability. Collect feedback through consumer testing for iterative refinement. A successful design seamlessly merges form, function, and brand messaging.

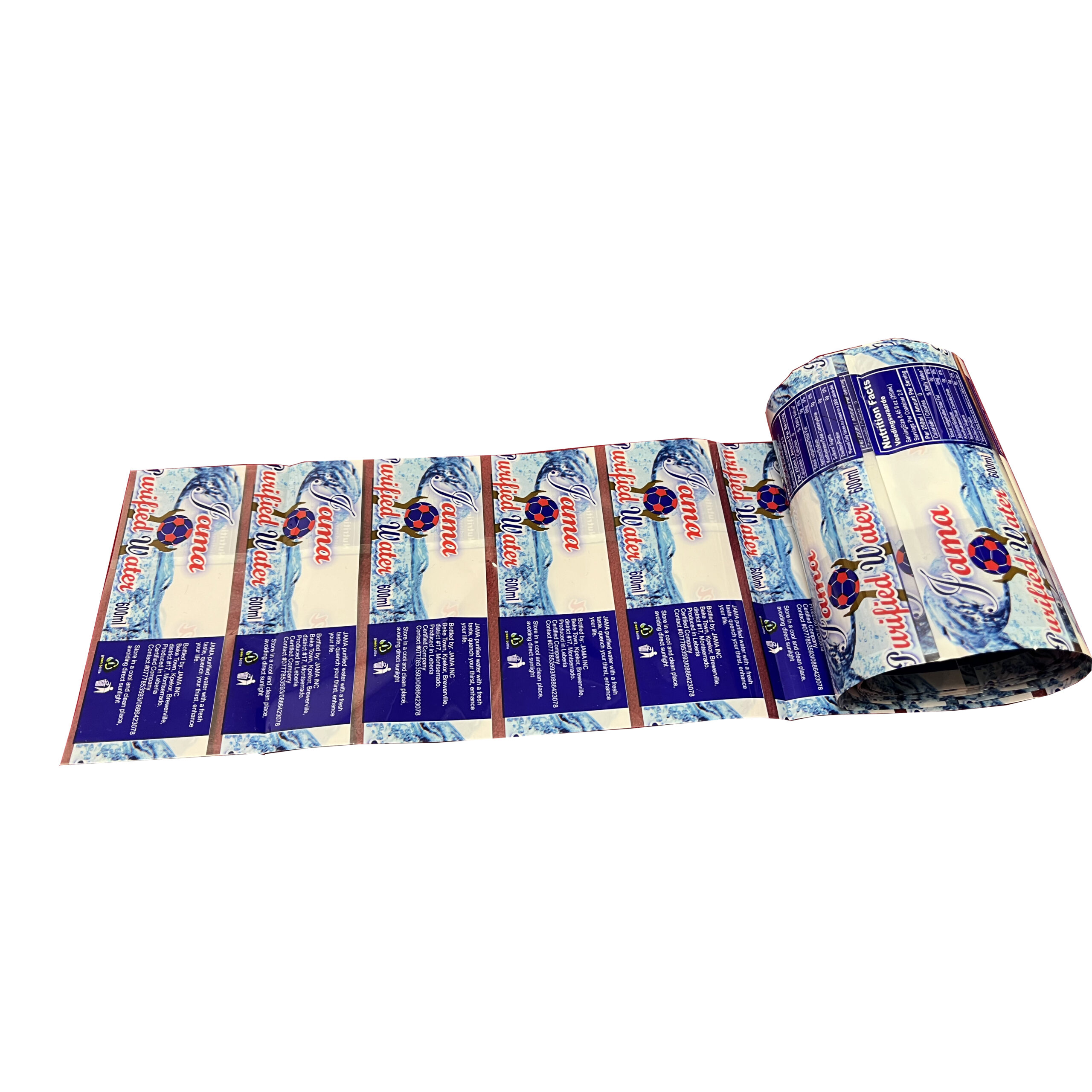

7. label design

Designing a PVC shrink label for bottled water demands attention to detail and practicality. Opt for a sleek and form-fitting design that complements the bottle shape. Prioritize water-resistant materials to ensure label durability. Utilize vibrant colors that evoke freshness and purity, aligning with the product’s essence. Clearly display brand elements, nutritional information, and recycling symbols. Incorporate shrink properties to snugly fit the bottle, creating a seamless and professional appearance. Test the label’s application process for efficiency and accuracy. The final design should marry aesthetics with functionality, enhancing the overall visual appeal of the bottled water packaging.

8. Material:

preform

sleeve label

water cap

- Select appropriate packaging materials, such as PET preform(used to make plastic bottle ), caps, and labels. Ensure that the chosen materials comply with regulatory requirements and are suitable for the Mauritian market.

9. Installation and maintain

The installation and maintenance of a water bottling plant are crucial for ensuring consistent and safe operations. Initial installation requires careful planning, adherence to regulatory standards, and efficient set-up of bottling equipment. Regular maintenance is essential to prevent breakdowns, ensure hygiene, and sustain production quality. Routine checks on water treatment systems, bottling machinery, and quality control processes are vital. A well-maintained plant not only safeguards product integrity but also promotes operational efficiency, reducing downtime and enhancing the overall reliability of the water bottling process. It is an investment in the long-term success and sustainability of the bottling business.

7. Staffing and Training:

- Hire trained staff for various roles in your factory, including machine operators, quality control personnel, and administrative staff. Provide training on hygiene, safety protocols, and machine operation.