This artile descripe how to industrials make soda bottle water. To start production soda bottle water for sale.

A lot people like drink carbonated water but do not want syrup of the carbonated water. Because syrup lead health problem and fat. So a lot people hope to drink soda water without syrup. Complete pure water with CO2 only.

To make soda bottle water, industrial manufacturers use a process called carbonation. This involves dissolving carbon dioxide gas in water, under pressure, to create the bubbles that give soda its fizz. The water is then bottled and sealed in containers, typically made of plastic, to preserve the carbonation.

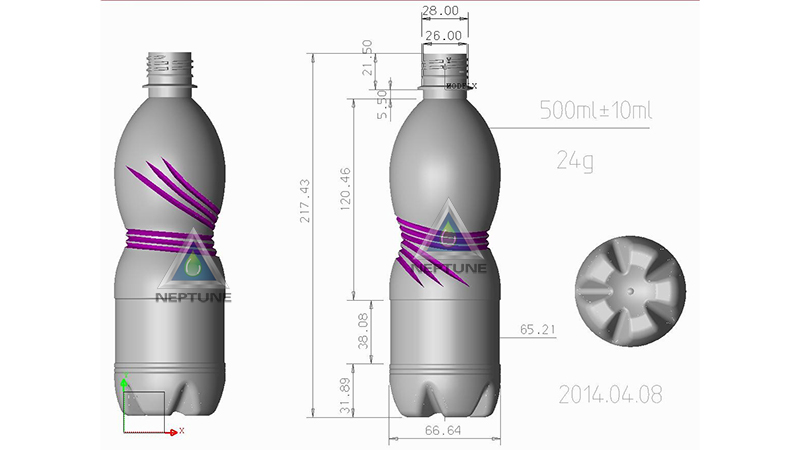

1.Got soda plastic bottle and soda bottle cap

Soda plastic bottle bottom is different with water bottle or juice bottle bottom. The soda plastic bottle have a 5 bumps (corrugation) at the bottom which not designed for beauty outlook. Because the soft drinking need lowering temperature to 3-5degree to good mixer with CO2. ( https://www.cnet.com/home/kitchen-and-household/appliance-science-the-compressed-chemistry-of-carbonation/ )

When filling cooling soft drinking into bottle. The bottle volume been changed and the bottle must not buckle because of this change in volume. The corner or the tip of the bump can slightly expand/contract without breaking which takes care of the change in volume of the liquid.

Facts for U: Why do Soft Drink Bottles have 5 bumps at the bottom??

2.Buy CO2 tank from local or CO2 company

CO2 is most important to mixer with pure water and producing soda water. It is better to got CO2 from local because it is belong dangerous liquid when shipment. Only have license CO2 company allow to complex shipment by sea.

If you are a commercial manufacturer of soda and you need a larger CO2 tank for your operations, you can purchase one from a local supplier or a company that specializes in providing industrial-sized CO2 tanks. These companies can provide tanks in a range of sizes, depending on your needs, and can also help you with installation and maintenance. It’s important to choose a reputable supplier with experience in providing CO2 tanks for the food and beverage industry, to ensure that you get a high-quality product and reliable service.

3. Soda water bottling machine

Once you have your CO2 tank and carbonation system in place, you will need a soda water bottling machine to package your product. There are many different types of soda water bottling machines available, ranging from small, manual systems to large, fully-automated machines. When choosing a soda water bottling machine, it’s important to consider factors such as the size and capacity of the machine, the type of bottles it can accommodate, and the level of automation and control it offers. You should also consider the overall cost and the availability of spare parts and technical support.

In normal temperature, pure water can only mixer a little CO2 which is meaningless. To reach industrials standard. It need mixer a lot CO2.

When the water temperature low to 3-5degree, It have a good mixer CO2. So the first step is cooling the water into 3-5 degree. Then use the CO2 mixer machine to mix the water with CO2.

Then use presssure balance filling machine to filling the soda water into the bottle and fast capper for seal well the bottle.

Metarials: CO2 tank, soda bottle, pure water,

Cooling machine, mixer machine, balance filling machine