Thanks for using AS 1000 AS2000 SL1000 S1 S2 AR1000 automatic water sachet packing machine, please read the Sachet Water Machine Instructions manual carefully before starting the machine.

Different type or model sachet water machine maybe a little different but all come from a basic model in the 1990s, and that practice grew after the introduction of Chinese machines for filling and heat sealing bags. You can know more about sachet water at wikipedia

CONTENTS

1. Sketch map of main parts

2. Main functions

3. Technics parameters

4. Functions

5. Operation characristic

6. Maintenance and maintain

7. Troubleshooting methods

8. Wearing spare parts

9. Electric components list

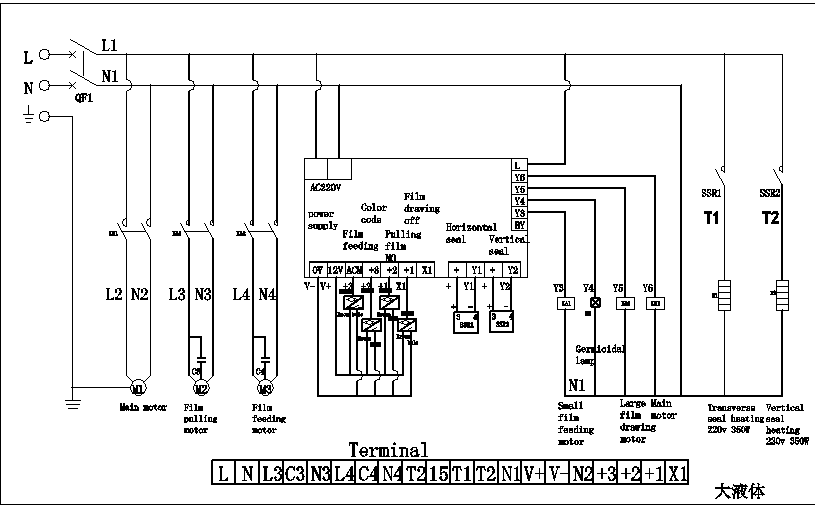

10. Electricity principle chart

It is forbade to touch the working components with hands when the machine is working, especially horizonal cutting and hot sealing.The frame must connect to the ground well, or it will be easy to injury for people.

1. Main parts item of sketon map

2. Main functions

The machine can pack kinds of non-carbon liquid material widely, especially source, vinegar,syrup,beverage, confect beverage(also the colded beverage makes ice bag), soy milk, milk, miniral water, greese bean curd and liquid sack.

3. Technics parameters

Yield capacity:1500~2200B/H

Packing volumn:100~500ml/B

Filling precision:±1%

Film width:240mm or 320mm(optional or choose others)

Power:Moter:singel phrase、three phrases 1.1KW

Vertical hot seal: 0.3KW;Horizonal hot seal: 0.5KW

UV sterilizer lamp15KW

Power supply:AC220V/Hz or AC380V(three phrases)

The weight of the machine:360kg

Dimension(L×W×H):750*700*1700mm

4. Function

1. Sack molding

2. UV sterilize

3. Vertical cutting hot seal

4. Date composed

5. Beeline tows sack

6. Ration filling

7. Horizonal cutting hot seal

8. Cutting sack

9. Count automatically

5. Operation points

5.1 The machine installs at aeration and dry place, is full of sunshine, makes it stable. It can fix four feet if neccessary

5.2 The tube which is going to fill material fills full of water(or 75℃ alcohol),the rubber tube cover the material out(avoid horinzon seal copper cake)and then lead to sewer(or recycle).It takes 5-10minites to wash pipe while starting the machine.It makes sure to reach the standard of food sanitation.

5.3 The plastic rool insert to the wheel, and adjust the central line, and make sure the same width when the roll is molding. Then screw the bolt separately. It is good through adjusting the pole of spring stress, ration automatically sway automatically. It is the best for braking well.

5.4 The sack pass through the tube, then buckle shaped utensil to make sure the strip symmetry. Date adjust to the daily date from up to down yearXX monthXX dayXX.

The vertical hot seal temperature adjusts to 120~150 degree,the horizonal seal temperature adjusts to 180~240 degree(No more than 260 degree, or the head of hot seal film is easy to damage),the exact temperature will be adjusted according to the film material and thickness.It can start to fill after pre-heat 20 minites, then it can produce continuously as long as the power is not off.

5.5 It can get the length of sack through adjusting the positon of pole on the winch.Adjusting-in is short, adjusting-out is long. First the power is off, then adjust. First loosen nut then adjust knob. Screw down the nut before starting the machine.

5.6 It can get the filling volumn throught adjusting ration pump on the winch. Adjusting-in is reduced, adjusting-out is enlarged. The same method with

5.7 The piston is adjustable module. When it used for a peroid, if it is found the piston pole droped, you could loosen the screw on the end piston. Screw piston clockwise, it makes piston large and it will eliminate the phenomonon of drop. ( Note: the adjusting must be small, or the piston is easy to damage). Screw down the screw to prevent loosening after adjusting.

5.8 It is ok to press the button and no need workers when it works. The output will show automatically by the counter. The the film is used up, it need to stop at once, and change into another film, then provide liquid and the machine starts.

It needs to pre-treat and filter when the solid substances is more in the tube which fill the liqui.When the vertical and horizonal seal no viscidity is worn after a peroid, it may loosen the tube to adjust. It can work after screwing down.( it is useless to adjust when it is worn completely). The liquid in the tube can not be more than 0.5meters to insure the precision. It can not be close when starts the machine, and when it has control valve in the liquid pipe.

5.9 Inspect the vertical and horizonal seal copper cake in a certain time, and clean up the sundries. Or it will affect the hot sealing. It can not be cleaned with metal tool and sand paper, or it will damage the surface and can not work. It should be cleaned with cloth or wooden organic solvent after the temperature is down, and clean up the sundries.

5.10 It should rub methylsilicone oil on the vertical and horizonal seal cloth with a certain time, in order to prolong the life of no viscidity cloth and increase the hot sealing.(methylsilicone oil model: 210~350CS)。

5.11 When it appears non-well seal, one sack connects another sack, leakage etc. it forbids pick it up with hands and kinds of tools. It should be stoped at once.

5.12 It is the best condition of all the programme and dimension before delivery. If it needs experienced technician to maintenance, and write down the dimension, then it can take down.

6. Maintenance and maintain

6.1 It need to wash the left liquid in the pipe in time when the machine stops. Or it will affect the next product quality. It needs to brush the plastic tube if necessary and rub the machine in time, and keep it dry and clean.

6.2 Inspect the movement components and the degree of lubricate with a certain time every times. Add 20# lubricate or lithium grease at any moment,Or it may not work normally and affect the life of the machine.

6.3 Inspect and clean up the sundries on the horizonal seal copper block every times.it can not appear scale deposit, or the temperature will be changed and the horizonal hot seal sack is abnormal.

6.4 If it is found abnormity, the power must be off immediately. It will reuse after troubleshooting.

6.5 When the temperature is below 0℃ in winter,it must thaw the pump and the ice in the pipe with hot water.Or the pole may break and the machine can not start.

6.6 The machine is fit for single plastic film thickness 80micronmeters. Every film weight should be below(320mm)18k and(240mm)14kg to insure the anti-pull intension, uniformity of thickness, lubricate. The temperature of horizon should be below 260℃, if not use the single plastic film we recommended, and appears hot seal is not well or broken sack rate is increased. The user will responsible for it.

7. Trouble and troubleshooting methods:

| Trouble | Reasons and troubleshooting methods |

| 1.The machine does not work | 1. Ask electrician to inspect the power supply, if it is lack of phrase or lose voltage. 2. If the power supply is on. 3. If the electric componences are well. |

| 2.Movement components hear abnormal noisies. | 1. Lack of lubricant 2. The screw is loosen and the position is changed 3. Wear and tear |

| 3. Liquid shortage or more or less | 1. The screw of pole is loosen 2. There is sundries in the inlet and outlet liquid single valve 3. The inlet liquid pipe has air or not seal well 4. Pressure pad of winch is not pressed well 5. The liquil level of material tank is over high |

| 4. Sack is sometimes short sometimes long , it is unstable | 1. Sack plier screw is loosen, rubber pad wears or has greese, it needs to use home detergent to clean 2. Material roll can not sway normally 3. Plastic film is over weight |

| 5. Vertical and horizonal seal has no temperature or the temperature in unstable | 1. Inspect the meter, if it works normally 2. If thermocouple is broken or loosened 3. If electric hot tube is broken 4. Power supply lack phrase, the end of cable loosen or drop. |

| 6. Hot seal and the cover is not good and the sack damaged rate is higher | 1. exchange non-viscidity cloth or adjust the position of non-viscidity cloth 2. Check if the rubber pad is plat or broken. If it is broken, it needs to change rubber pad 3. The output of fill is over large, it need to remain a few air room 4. Adjust to the fittable temperature |

| 7. Operationer fell tingle | 1. If the electric protector is damage 2. The cable line connect is wrong or not connect well 3. The machine should connect to the ground well 4. Hot seal copper block should be insulated with outside well 5. It does not permit the liquid pouring on the end of cable line or electrical appliances |

| 8. Horizonal seal cutting is abnormal, sometimes it is connected between two sacks, and anti-pressure intensity is not enough | 1. Clean the sundries on the horizonal seal copper block at once 2. Check if the Polyter afuoroethyenea thermal bafflen the copper block is loosen, shaped and damaged 3. Exchange rubber pad 4. Plastic film thickness should be 80micron meters 5. Adjust the pressure of horizonal seal copper block 6. Check if the knife-edge on the copper block has scar |

| 9. Pump is dropped and leakage | 1. The distance is increased between piston rings 2. Solution: First loosen the screw on the pole of pump pisto, screw down a little blockwise.( It can not screw down over, or the piston will be damaged) |

8. WEARING PART LIST

| Name | UNIT PRICE |

| Horizontal, vertical seal (thermocouple) K-type 1.5 m / 2 m | USD 3 |

| Heater 185mm/195mm | USD 3 |

| Xi Sifu Article | USD 4 |

| Temperature controller | USD22 |

| 500 ml pump | USD140 |

| GFCI | USD4.5 |

| Proximity switch | USD4 |

| Horizontal sealing tape | USD 2 |

| Vertical sealing strip | USD 2 |

| Relay | USD 5.5 |

| UV lamp | USD 5 |

| High temperature tape | USD 2.5 |

| Horizontal sealing knife, knife shaft seal | USD 30 |

| 1 set of pump seals | USD 10.5 |

| Coder | USD 260 |

| Fuse | USD 0.5 |

| High temperature cloth | USD 2 |

| Counter | USD 6 |

| Fork wheel nylon slip | USD 5.5 |

| Photocell | USD 47 |

| Membrane small motor 25W 1:15 | USD 52.5 |

| The film feeding motor 120W 1:30 | USD 122 |

| Main Motor | USD 79 |

| Reducer | USD 75 |

| Transformer | USD 28 |

| AC contactor | USD 1 |

| Solid State Relay | USD 5 |

| Cross seal spring | USD 1 |

| Membrane electrical gear | USD 10.5 |

| Membrane electrical plastic cap | USD 1 |

| Single-vessel switch | USD 1 |

| Dual boat switch… | USD 1 |

10. Electricity principle chart