What this price included?

| 1 | BM-A2 Blow Molding Machine | 1SET | |

| BM-A2 Preform unscrambler | 1SET | ||

| 2 | 1.6m3/min 30Kg HP Air Compressor, Shangair Brand | 2SET | |

| 3 | 1.6m3/min 10Kg LP Air Compressor, Shangair Brand | 1SET | |

| 4 | 2.0 m3/min 30Kg Air Dryer (Inside 2psc air filter) | 1SET | |

| 5 | 0.6 m3/30Kg Air Tank | 1SET | |

| 6 | 3HP Mould Chiller(Air Cooling) | 1SET | |

| 7 | Air tube & Spare parts | 1SET | |

| 8 | Two cavity Blow Mold (250-2000ml) | 1SET | |

| 9 | TC-7.0 PRE-TREATMENT (Optional FRP pre-treatment filter tank,cheaper USD 520) | Original pump | 1SET |

| Quartz Sand Filter | 1SET | ||

| Activated Carbon Filter | 1SET | ||

| Precision filters | 1SET | ||

| Connecting pipe and else | 1SET | ||

| 10 | RO-1000I (2000L / H) RO unit(Eight sets Hydranautics Dow 4040) | 1SET | |

| 11 | RS-3 Water Softener | 1SET | |

| 12 | UV-40W Ultraviolet sterilization assembly | 2SET | |

| 13 | SOZ-6G Ozone Generator And Mixing System (Air source) | 1SET | |

| 14 | 2000L 1080*2100 SUS304 Raw Water Tank (Thickness 0.5mm) | 1SET | |

| 15 | 2000L 1080*2100 SUS304 Pure Water Tank (Thickness 0.5mm) | 1SET | |

| 16 | Connecting pipe and Spare part | 1SET | |

| 17 | NF 8-8-3 Washing-Filling-Capping (Three-in-One Unit) Machine | 1SET | |

| 18 | Air compressor | 1SET | |

| 19 | Convey System (2M Air conveyor,1psc air blower,2M conveyor,1psc motor) | 1SET | |

| 20 | Light check | 1SET | |

| 21 | Change Bottle Shape Mold | <3SET | |

| 22 | HP-250 HIGH SPEED AUTOMATIC SLEEVE LABELING MACHINE (Come with the steam shrinking tunnel &steam generator&six meters conveyor belt, motor) | 1SET | |

| Change Bottle Shape Label Mold | 3SET | ||

| 23 | VIDEOJET 1210 INK JET PRINTER (Original Videojet 1psc ink, 1psc Diluent) | 1SET | |

| 24 | NP-W250 AUTOMATIC WRAP SHRINK PACKAGE MACHINE (Come with Automatic film wrap machine; Bottle convey machine; Thermo shrinkage package machine; Main controlling case; Convey machine rack) | 1SET | |

NEP-2000 water bottling plant is automatic complete bottle water production line. Shorter middle producing process and fast got final wrap package bottle water which save factory room. All middle goods sending with conveyor belt without any human being hand touch.

NEP-2000 Water Bottling Machine Plant is a state-of-the-art facility designed for efficient and automated production of bottled water. With a production capacity of 2000 bottles per hour, this plant is equipped with advanced technology to handle the entire bottling process seamlessly. The key features of the NEP-2000 plant include:

- Automated Processes: The water bottling plant incorporates automated processes from bottle blowing, water purification, washing, negative pressure filling, settling cap, buckling cap, and screwing cap to bottle labeling, printing, and packing.

- Space-Efficient Design: The bottling plant is designed to optimize space utilization, ensuring a compact layout for streamlined production without compromising efficiency.

- Hygienic Operation: To maintain high hygiene standards, the entire process is designed to minimize human touch. Automated conveyors handle the transportation of bottles, reducing the risk of contamination.

- Fast Production: With a production speed of 2000 bottles per hour, the NEP-2000 ensures a quick and efficient manufacturing process, meeting the demands of a high-paced bottling operation.

- Quality Assurance: The making bottle water plant is equipped with quality control measures to ensure that each bottle meets the specified standards, providing assurance of purity and safety.

- Complete Bottle Water Solution: The NEP-2000 water bottling plant is an all-in-one solution, covering the entire spectrum from bottle production to final packaging, labeling, and printing.

- User-Friendly Interface: The machine is designed with a user-friendly interface for easy operation and control, allowing for efficient management of the entire bottling process.

- Stainless Steel Construction: The use of stainless steel in critical components ensures durability, cleanliness, and adherence to sanitary standards.

Overall, the NEP-2000 Water Bottling Machine Plant offers a comprehensive and efficient solution for businesses looking to enter or expand in the bottled water production industry.

Can the machine handle different bottle sizes and shapes?

Yes, the NEP-2000 water bottling machine plant is designed to handle different bottle sizes and shapes. It comes with the flexibility to accommodate various plastic bottle sizes ranging from 200ml to 2000ml. The machine is equipped with molds that can be easily changed to fit different shapes, allowing for versatility in production. Whether you need bottles for 200ml, 500ml, 1000ml, 1500ml, or 2000ml, this water bottling machine plant can adapt to your specific requirements.

What Is The Production Capacity Of The Water Bottling Machine?

24Hours production 48000 botttles per day

350ml Bottled Water: 2000 bottles per hour

500ml Bottled Water: 2000 bottles per hour

1000ml Bottled Water: 1300 bottles per hour

1500ml Bottled Water: 1000 bottles per hour

The NEP-2000 bottle water production line operates continuously for 24 hours, resulting in a daily production capacity of 48,000 bottles. The standard production speed is 2000 bottles per hour depend on 500ml bottle water, considered as synchronized production for this line. It’s essential that every machine in the line has a capacity greater than or equal to 2000 bottles per hour. The blow molding machine is highlighted as the most expensive machine in the line, emphasizing the importance of its speed being 2000 bottles per hour to achieve maximum efficiency. Other machines in the line have capacities exceeding 2000 bottles per hour.

what kind of bottle water is this bottling plant can produce?

The NEP-2000 water bottling machine plant is versatile and can produce various kinds of bottled water. It is suitable for bottling the following types of water:

- Mineral Water

- Pure Water

- Spring Water

- Distilled Water

Whether you are producing water with added minerals, purified water, water from natural springs, or distilled water, this bottling machine plant is designed to meet the specific requirements of different types of bottled water production.

NEP-2000 bottle water bottling plant offers several advantages:

- Automatic Conveyor Bottle: To adhere to Hazards Analysis Critical Control Point(HACCP) and eliminate human touch, Neptune incorporates an automatic blow molding machine air conveyor outlet for plastic bottles. This feature enables automatic connection with the air conveyor inlet of the 3-in-1 filling machine, saving labor and maintaining cleanliness.

- Stainless Steel Production Box: Both the bottle-making machine and 3-in-1 filling machine are enclosed in a stainless steel box. This protective measure minimizes air pollution for both the bottles and bottled water, ensuring a clean production environment. Maintaining cleanliness is crucial for quality production.

- Shorter Production: NEP-2000 focuses on smaller speed machines ranging from 1000 bottles per hour to 8000 bottles per hour. This deliberate choice aims to reduce the production scale, saving space and minimizing the risk of contamination during the middle stages of production. This approach is particularly beneficial for smaller-scale operations.

What types of materials can the water bottling plant work with?

PET Preform

PET preforms are semi-finished products used in the production of PET (polyethylene terephthalate) bottles and containers. These preforms are initially shaped like test tube-like structures and are later heated and blown into the final bottle shape using a blow molding machine.

pE water Cap

PE water cap is a cap made from polyethylene (PE), a type of plastic known for its flexibility, toughness, and chemical resistance. These caps are commonly used in the bottling industry for sealing water bottles. Polyethylene caps are popular due to their reliable performance in preventing leaks and maintaining the freshness of the contents.

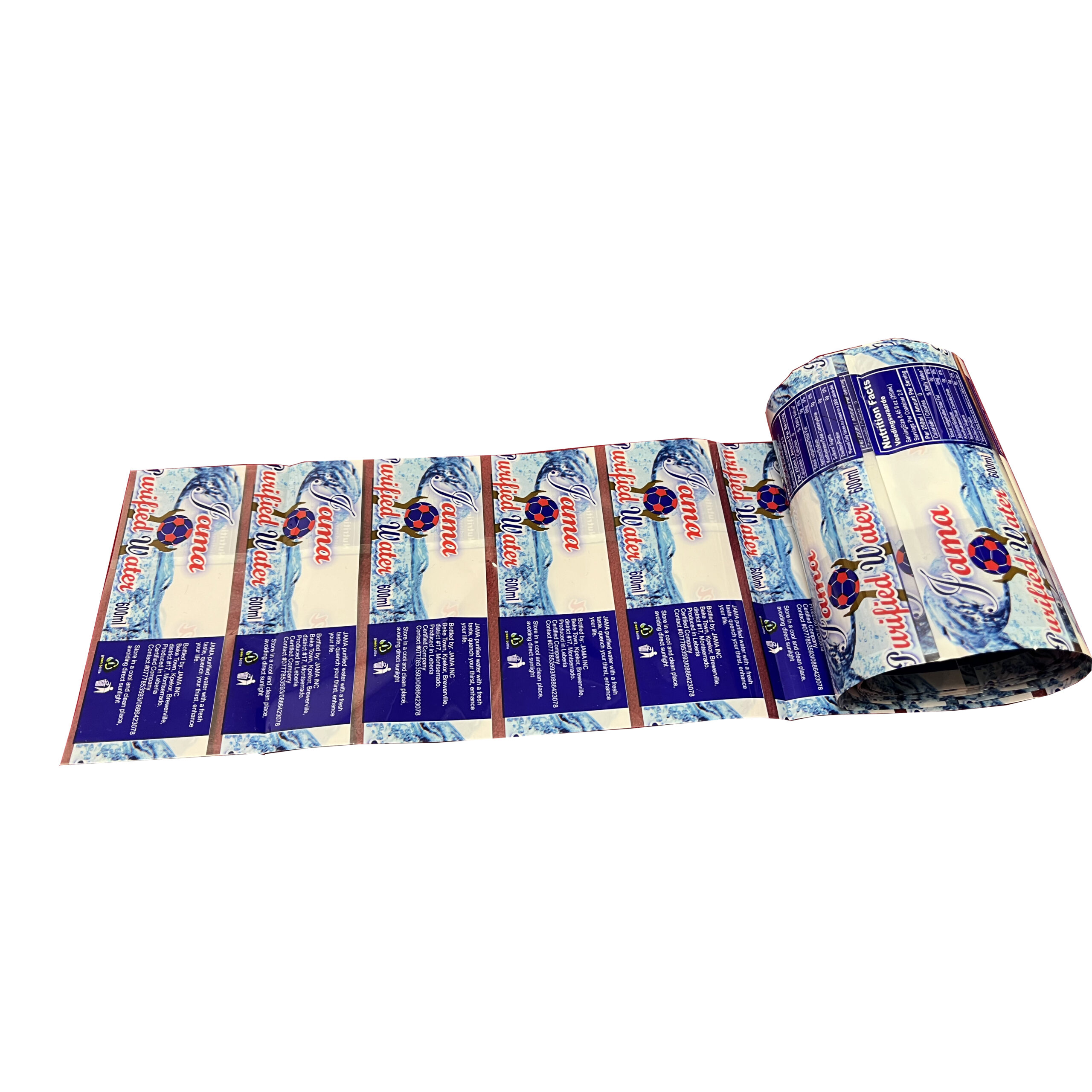

PVC Shrink label

A PVC shrink label, also known as a shrink sleeve or shrink wrap label, is a label made from polyvinyl chloride (PVC) material that shrinks when heat is applied. These labels are widely used in the packaging industry, including on bottles, containers, and various products. The PVC shrink label is designed to conform tightly to the shape of the container when heat is applied, creating a secure and visually appealing packaging solution.

PE Wrap film

PE wrap film, also known as polyethylene wrap film, is a type of packaging material made from polyethylene, which is a widely used plastic known for its flexibility, clarity, and durability. PE wrap film is commonly used for wrapping and protecting various products, providing a secure and transparent layer of packaging. Here are some key features and uses of PE wrap film:

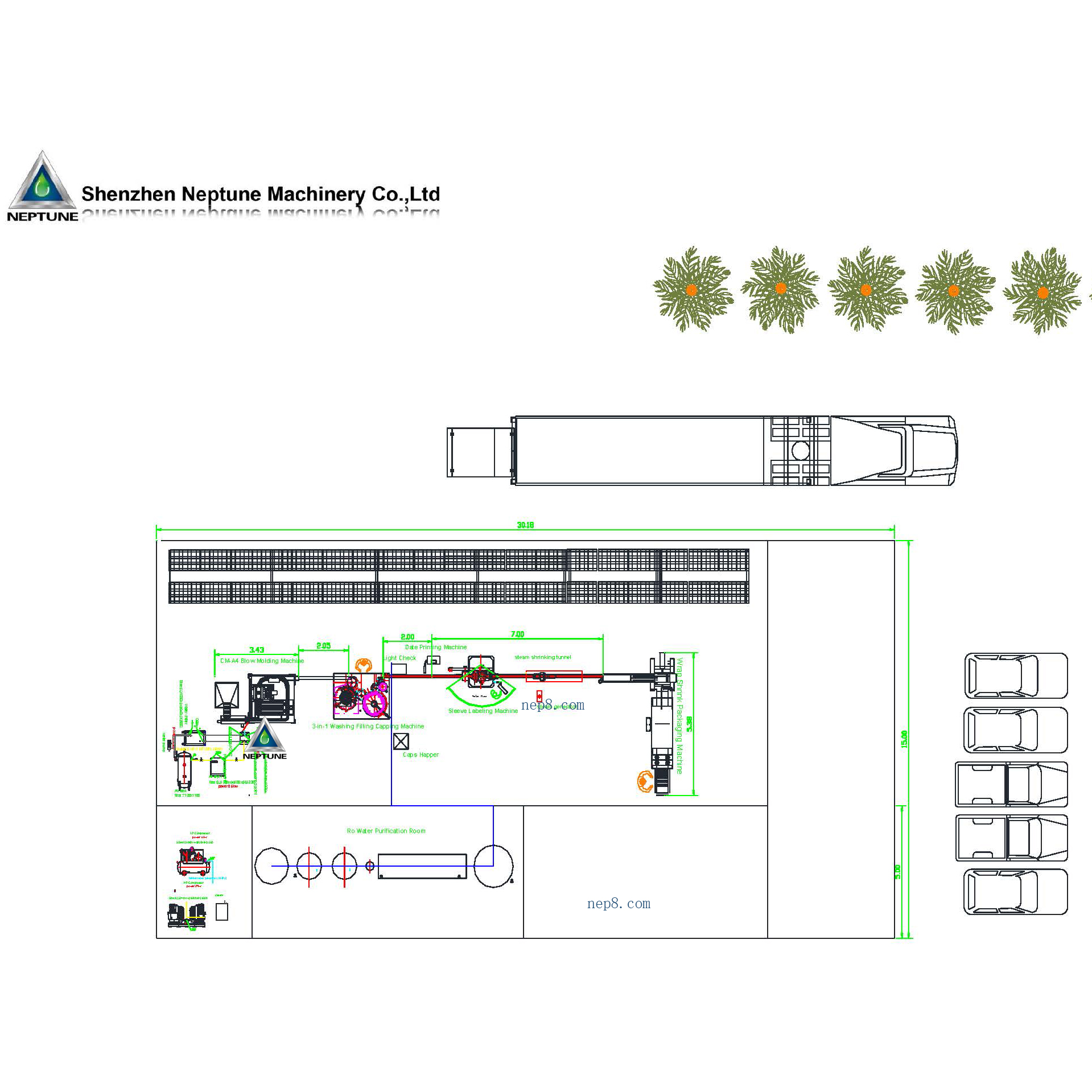

water bottling facility Layout

The space requirements for setting up the NEP-2000 water bottling machine plant are as follows:

- Location: It is advisable to set up the plant on the first floor for easy access for trucks to enter and load the bottled water products.

- Production Room: The production room should ideally have a minimum size of 20 meters in length and 10 meters in width. A larger space is beneficial for accommodating the machinery and ensuring a smooth production process.

- Storage Room: Allocate a space of at least 50 square meters for storing materials needed in the production process. This room is crucial for keeping raw materials and supplies organized and easily accessible.

- Final Product Room: Designate another space of at least 50 square meters for the final product room. This area is where the finished bottled water products will be stored before distribution.

- Additional Considerations: Consider the layout and arrangement of the machinery, production lines, and storage areas to optimize the workflow and ensure efficiency. Adequate space should be provided for workers to move around safely.

Having sufficient space and a well-organized layout is essential for the smooth operation of the water bottling plant. It allows for the proper placement of equipment, easy material handling, and effective storage of both raw materials and finished products. If you have specific requirements or need further details, feel free to ask!

Video of the 2000bph water bottling line

The NEP-2000 Auto Water Bottling Plant is highly favored by our customers due to its versatility and numerous advantages. This bottling plant is capable of producing various shapes and volumes of bottled water by simply changing the mold, providing a flexible and efficient solution.

Key Features of the NEP-2000 Auto Water Bottling Plant:

- High Automation Level: The plant boasts advanced automation, streamlining the bottling process for enhanced efficiency.

- Compact Structure: Despite its high capacity, the plant maintains a compact and space-efficient design.

- Beautiful Appearance: The overall aesthetic appeal of the plant adds a professional and visually appealing touch to the production facility.

- Convenient and Simple Operation: User-friendly controls and straightforward operation contribute to ease of use.

- Safe and Reliable: Built with safety in mind, the plant ensures reliable performance and minimizes risks.

- Adjustable Continuous Production Capacity: The production capacity is adjustable to meet varying demands, allowing for efficient production planning.

- Suitable for Different Bottle Shapes: Primarily designed for round or square polyester bottles, the plant accommodates various specifications to meet user requirements.

- Adaptable Design: Minor design modifications can be made to tailor the plant to specific user specifications, ensuring versatility.

The NEP-2000 Auto Water Bottling Plant is an excellent choice for those seeking a comprehensive solution for water bottling. Whether it’s the ability to handle different bottle shapes, user-friendly operation, or a compact footprint, this plant is designed to meet the diverse needs of the beverage industry. If you have any specific inquiries or if there’s more you’d like to know, feel free to ask!

Whole 2000BPH water Bottling Line Mainly Included:

The NEP-2000 Auto Water Bottling Plant operates through a seamless and automated process to ensure efficient production of bottled water. Here’s a breakdown of the key steps:

plastic Bottle Making Machine

It is a manufacturing equipment designed to produce plastic bottles through the process of blow molding. This technology involves inflating a heated plastic preform or parison inside a mold to create a hollow object, which is then cooled and ejected as a finished bottle.

2000Liter/Hour RO Water Purification Machine

Water treatment system designed to purify and filter water through the process of reverse osmosis. Effectively removes impurities, contaminants, and minerals from water, providing clean and purified water suitable for various applications.

Water Bottling Machine 3in1

- The bottles are then conveyed to the 3-in-1 filling machine through the air conveyor system.

- The 3-in-1 machine performs washing, filling with pure water, and capping in a synchronized process.

Date Laser Printer

A bottled water date laser printer is a specialized printing machine designed to imprint production or expiration dates, batch numbers, and other essential information directly onto the surface of bottled water containers using laser technology.

Sleeve Labeling Machine

- A sleeve labeling machine automatically places PVC labels in the correct position on the bottled water.

- The bottles with labels undergo shrinking in a shrink tunnel, ensuring a secure and snug fit.

Wrap Shrink Packaging Machine

- Finally, a wrap shrink packing machine uses PE film to package multiple bottles (6/12/20/24) together.

- This packaging method enhances convenience for customers to carry multiple bottles.

How an 2000BPH water bottling line profit ?

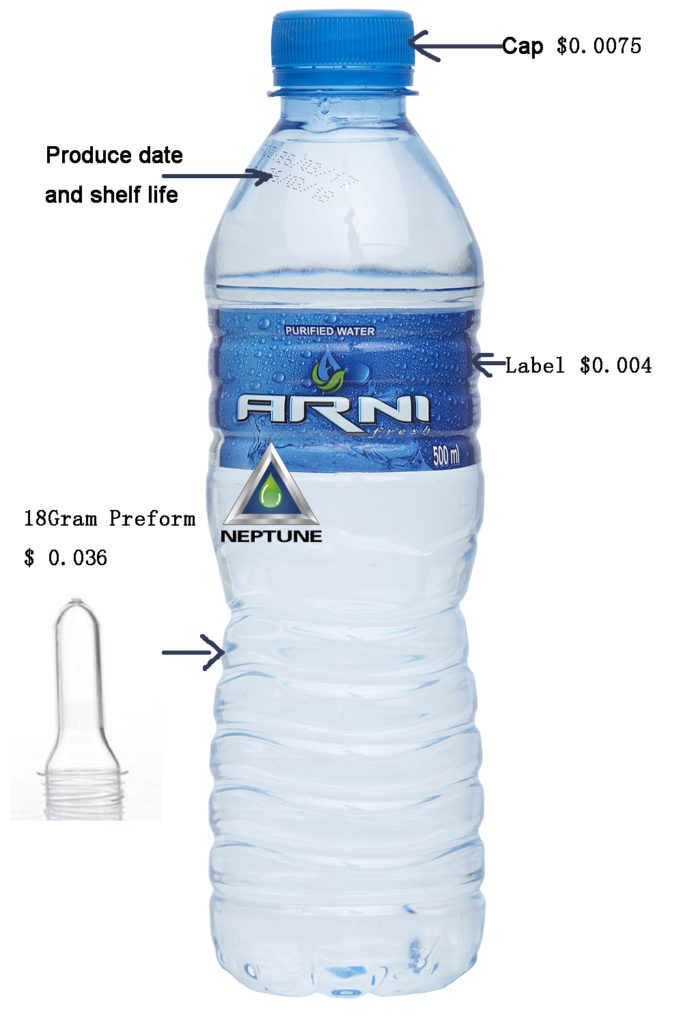

500ml bottled water as sample Materials cost as follow:

| Cap | $ 0.0075 |

| Bottle=Preform | $ 0.036 |

| Label | $ 0.004 |

| Wrap Film | $ 0.003/psc |

An 500ml bottled water materials cost $ 0.0505, usually factory selling it at $0.010-0.12 to agent and shop when competition is fierce. And some factory selling it at $ 0.2 if local only one factory.

An 2000BPH water bottling line per day can produce 20000psc 500ml bottled water. Per month can produce 0.6 million piece 500ml bottled water. If lower profit 0.05 per bottle. Bottled water factory can profit USD 30000 per month. Then cut labor and water, electricity cost which total not over USD 8000. So that one 2000bph water bottling line can profit USD 22000 per month. If local just only one factory. without any competition. The profit willing increase 300% .