fob price $ 11,000.00

What this price included?

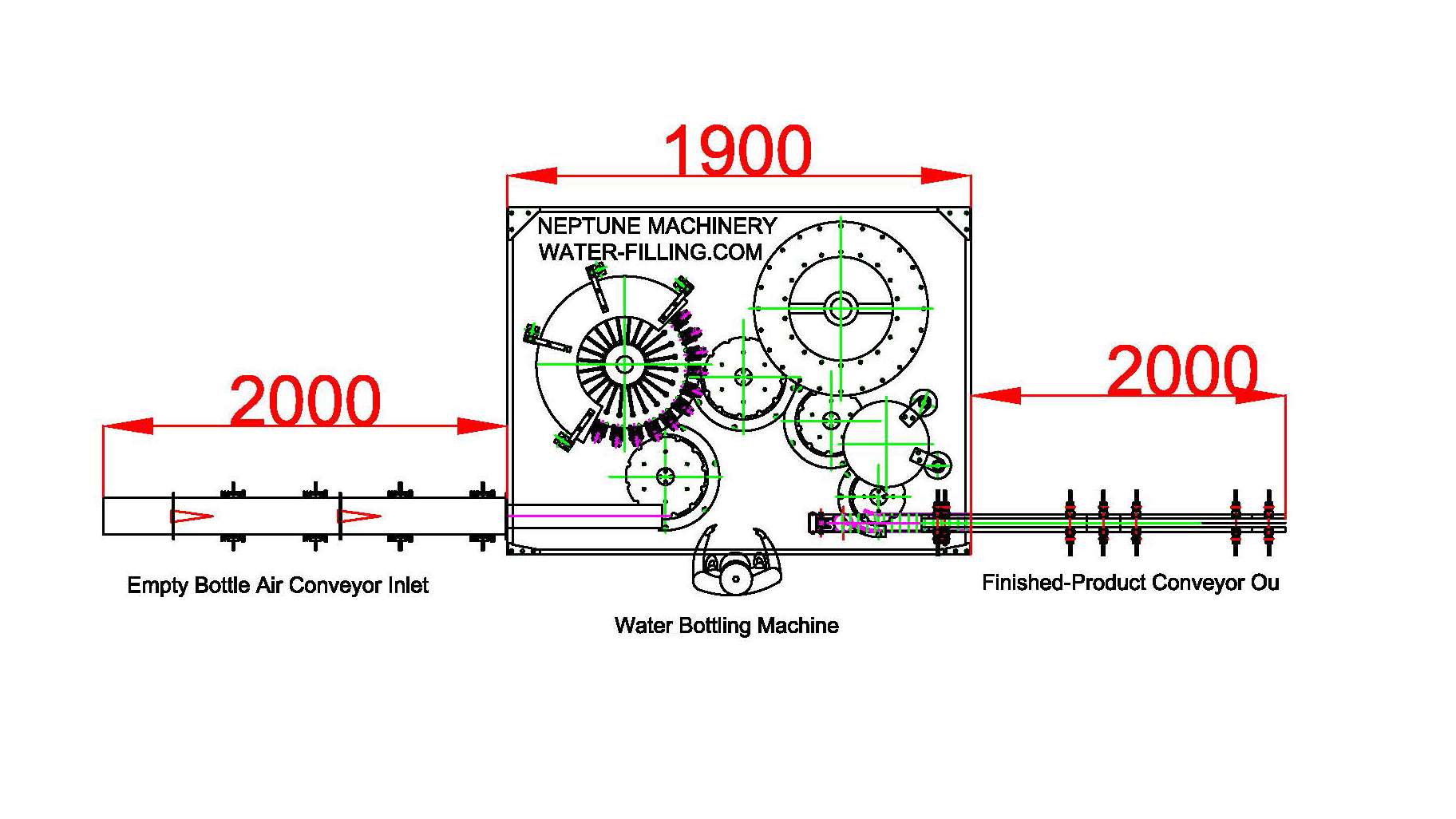

- 883 washing filling capping machine

- 2 meter inlet air conveyor with fan

- 2 meter outlet conveyor belt with motor

- Light check

- Water-Cap auto loading and feeding equipment

Does the machine support different bottle sizes?

🌐 Versatility Unleashed: 883 Type 3-in-1 Water Bottling Machine!

✨ Supports Bottle Sizes: 200ml to 2000ml

Experience unmatched flexibility in your bottled water production with our 883 type 3-in-1 machine. Through change an shape mold to fit different volume and shape plastic bottle.

All-in-One water bottling system collect rinser filler and capper for bottled water.

It is the smallest monoblock filling machine in the world. It only have 8 psc washing head, 8 psc filling head and 3 psc filling head. It can reach 2500 bottles per hour depend on 500ml bottle. And it can running 24 hours per day to reach 60000 bottles per day.

- Best monoblock water bottling machine for pure water.

- PLC control, easy use.

- Mature design, large production, standard market test.

- Every valve finished working on one bottle and will moving to next bottle around the 360 degree disk. It is continued working without any stop.

- It is the newest water bottling machine. Increase filling efficiency with less cost.

- It is fully automatic water bottling machine which save worker labor.

What is the production capacity of the water bottling machine?

- 2000ml Bottled Water: 1000 bottles per hour

- 1500ml Bottled Water: 1000 bottles per hour

- 1000ml Bottled Water: 1300 bottles per hour

- 500ml Bottled Water: 2500 bottles per hour

- 350ml Bottled Water: 2500 bottles per hour

Parameter

| MODEL | NF 8-8-3 |

| Capacity of production | 2000-2500 bottles/h |

| Washing Head Quantity | 8 |

| Filling Valve Quantity | 8 |

| Capping Head Quantity | 3 |

| Filling Temperature | Normal temperature |

| Main Motor Power | 3.42KW |

| Bottle diameter | 40-102mm |

| Bottle height | 130-30mm |

| Air resource pressure | 0.5Mpa |

| Filling Water | 1-1.5T/H |

| Consume Water | 0.8T/H |

| Control Type | PLC |

| Central Diameter of Filling Valve | 320mm |

| Central Diameter of Capping Machine | 120mm |

| Central Diameter of Washing Machine | 320mm |

| Dimension | 1850 X 1450X2000mm |

| Net Weight: | 1200kg |

Video Of The Rotary Bottled Water Filling Machine

Its speed only 2000bottles per hour depend on 500ml bottled water. Production is very stable.

It is an best machine for people do not have experienced. All is setting well before out factory and do not need change any setting.

It use rotary type washing filling and capping so that more faster and efficient than linear filling machines, as they can fill and cap a large number of bottles in a short period of time. They are also more accurate, as they use precise measuring systems to ensure that each bottle is filled to the same level.

What is the overall footprint and space requirements for the machine?

The main machine take 1500mm width and 1900mm long, It inlet air conveyor belt 2meter and outlet 2meter conveyor belt. So it will take at least 6 square meter room. If you want buy an complete water bottling plant and got the whole factory footprint and space requirement, please contact NEPTUNE MACHIENRY.

8set catch bottle for washing bottle. The bottle are washing outside and inside by the flushing water from the moving washing head. 8 set filling valve filler pure water into the bottle and moving with the bottle together.

Then cap loading and feeding cap for every pass bottle water. 3 set magnetic twist full-tooth capping heads will screw bottle water with cap. It is automatic slip to ensure cap will not damaged by too much tightening.

Is the machine fully automatic or semi-automatic?

🔄 Automated Flow: 3-in-1 Water Bottling Machine for Effortless Production

- Connects to Bottle Making Machine: Fully automatic at the beginning for an uninterrupted production flow.

- Conveys to Labeling Machine: Streamlines the process by automatically transporting product bottles for labeling.

Experience efficiency from start to finish with our 3-in-1 Water Bottling Machine. Simplify your production line for seamless and automated operations. Ready to elevate your bottling process?

Why 304 Stainless Steel is Essential Inside Triple-Action Filling Machines

In the high-purity world of water filling, every material choice impacts product integrity. Triple-action filling machines (washing-filling-capping) universally rely on AISI 304 stainless steel for internal components.

1. Corrosion Resistance

With 18% chromium and 8% nickel, 304 steel withstands acidic/alkaline cleaning agents (CIP/SIP systems) and chloride-containing liquids without rust or pitting.

2. Hygiene Compliance

Non-porous surface prevents bacterial adhesion and enables sterile cleaning.

Meets FDA, EU 1935/2004, and 3-A Sanitary Standards for food/pharma contact.

3. Structural Durability

Maintains strength at high temperatures (up to 870°C) during steam sterilization.

Resists mechanical wear from moving parts (conveyors, filling valves).

4. Product Protection

Prevents iron ion contamination that alters taste/color in sensitive products (e.g., mineral water, juices).

Non-reactive surface preserves flavor and chemical composition.

5. Lifecycle Economy

50+ year service life reduces replacement costs. Polished surfaces (Ra ≤ 0.8 μm) minimize product adhesion and cleaning time. While 316 steel offers superior chloride resistance, 304 remains the cost-effective standard for non-marine applications. Its unmatched blend of cleanability, durability, and regulatory acceptance makes it the only responsible choice for triple-action filler interiors—where purity meets performanceaterter

Why Modern Bottled Water Plants Must Adopt Automatic Water-cap Loading and Feeding Machine

Why Bottled Water Producers Can’t Afford to Wait

✅ Meet FSSC 22000 & FDA Hygiene Mandates

Eliminate human-dependent CCP failures with closed-loop sanitation.

✅ Slash Production Costs

Reduce labor by 20% + cut lid-washing equipment/utilities.

✅ Eliminate Downtime

No more jams from misaligned lids. 98.7% line efficiency guaranteed.

✅ Protect Brand Reputation

Zero recall risks from contaminated caps.

In the high-stakes world of bottled water production, hygiene, efficiency, and consistency aren’t just goals—they’re non-negotiable standards. Here’s why automated water-cap loading and feeding machine is no longer a luxury, but a critical upgrade for every forward-thinking facility:

The Hidden Costs of Manual loading cap

Traditional cap feeding relies on repetitive human labor:

☑️ Operators constantly load & monitor cap

☑️ Direct hand-contact risks microbial contamination

☑️ Inconsistent placement causes line jams/downtime

☑️ Separate washing steps increase complexity & costs

How Automatic Water-cap Loading and Feeding Machine Transforms Your Production Line

1. Labor-Free Operation

- Pour 5,000 lids → Walk away for 2+ hours

- Saves 1 workers per shift

2. Contactless Hygiene Shield

- Water-cap never touched by human hands after loading

- Sealed pneumatic conveyance prevents airborne contaminants

3. In-Transit Sterilization

- Patented CleanFlow™ Technology: Food-grade sanitizer injected during air conveyance

- 360° disinfection while lids travel to filler

4. Gravity-Optimized Delivery

Smooth airflow ensures perfect alignment at capper

Cap elevated above filler inlet