FOB PRICE $10,400

What this price included?

| NO | NAME | QC | TOTAL FOB PRICE |

| 1 | BM-S10L BLOW MOLDING UNIT | 1 SET | USD 6,110.00 |

| ROTATING OVEN | 1 SET | ||

| 2 | High pressure air compressor(1.2M3/min 30KG); Brand Shangair | 1 SET | USD 2,050.00 |

| 3 | Air Dryer(2.0m3/min 30kg) | 1 SET | USD 700.00 |

| 4 | Air Filter(2.0m3/min 30kg) | 2 SET | USD 400.00 |

| 5 | Blow Mold 10L | 1SET | USD 1200.00 |

| 6 | Spare part & High pressure Pipe | 1SET | FREE |

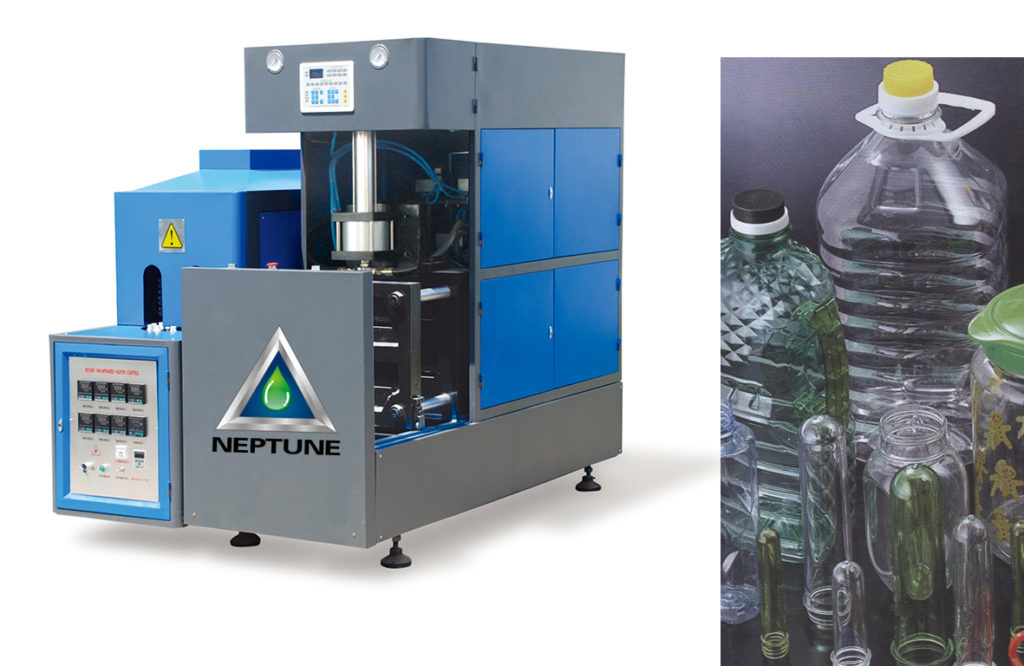

Why neptune 5-10liter blow molding machine?

Middle bottle water became more and more popular.

Family became small. And a lot people became living in the center of the city which house room became small.

Table water dispenser with an 5gallon bottled water is not very convenient. But an 5liter-10liter bottle water is very convenient.

1.Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the perform rotated and heated equally.

2. The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements for the action and blow. It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

3. The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

4. The machine can be operated in the step-by-step mode and the semi- auto mode.

5. The machine is small with low investment, easy and safe to operate by one person.

PET Oil Bottle Making Machine heating and blowing hollow tube preform into light and thin pet plastic bottle. A lot cooking oil company use the pet plastic bottle as container for cooking oil.

Are you in the cooking oil industry and seeking a cost-effective solution for bottle production? Your search ends here! [NEPTUNE MACHINERY], a trusted China-based manufacturer, proudly presents the Semiautomatic Cooking Oil Bottle Making Machine — a perfect blend of affordability, top-notch quality, and user-friendly design

Key Features:

🚀 Affordable Excellence:

- Our Semiautomatic Cooking Oil Bottle Making Machine combines unbeatable prices with the assurance of high-quality bottle production. Elevate your packaging without breaking the bank!

🔧 User-Friendly Design for Seamless Operation:

- Simplify your bottle-making process with our machine’s straightforward design. Operators can navigate and maintain the equipment effortlessly, ensuring smooth production without complications.

🌐 Global Trust, Local Impact:

- Trusted globally, our machine is designed to meet international standards while catering to the specific needs of your local cooking oil production.

Applications:

🍳 Tailored for Cooking Oil Bottling:

- Specifically designed for the cooking oil industry, our machine ensures the production of bottles that meet the highest standards of quality and hygiene.

🏭 Versatile Across Industries:

- Adapt to various bottle production needs with a machine that delivers high-quality results for different applications.

What is 5-10L Cooking Oil Bottle Making Machine ?

5-10L bottle semiautomatic blow molding machine is suitable for producing PET plastic containers and bottles from 5000-10000ml. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle etc.

| Main parameter: | ||

| Model | BM-S10L | |

| Container | Product material | PET |

| Volume | 6L-10L | |

| Theoretical output | 250PCS/H | |

| Preform length | 15mm-460mm | |

| Preform inner diameter | Φ15mm-200mm | |

| Moulding | Max.mould plate Dimenstion(L x W) | 470x500mm |

| Max.mould thickness | 370mm | |

| Clamping force | 100KN | |

| Mould opening stroke | 350mm | |

| Machine size and weight | Main machine (L x W x H) | 193*72*183cm |

| Main machine weight | 800Kg | |

| Heater (L x W x H) | 187*63*145cm | |

| Heater weight | 250Kg | |

| Power | 17.5kw | |

How does an 5-10 liter Cooking Oil Bottle Making Machine working?

5-6L bottled can setting 2cavity mold, So that once can produce 2psc bottle. And blow moling machine speed can reach 450bottles per hour. But big bottle need mold size big, So that 8-10L bottle only can setting 1cavity mold. Once can produce 1psc bottle. And production is only 250bottles per hour.

BM-S10L is the model. And it heating the preform to idea temperature. Then worker moved it into the blow mold of the blow molding machine. The machine made use the air blowing into preform. Then can blowing into idea 5-10l bottle according the mold.

Why Use Pet Plastic Bottle Container Cooking Oil?

But glasses bottle easy broken which lead cook oil flow everywhere while plastic bottle will not easy broken even a lot collision.

TRANSPARENT

Customer worried about the cooking oil quality so that an transparent cooking-oil-bottle can let customer at a glance of the oil.

It will help a lo cooking oil company increase sales volume.

LIGHT AND THIN

Glass bottle is also heavy while plastic bottle is light. Lower than 1liter cooking oil bottle sometimes use glassess. But most bigger than 2liter cooking oil bottle is use the pet plastic bottle.

It is not only strong and not easy broken. But also very light to carry for customer.