FOB PRICE USD 35850

What this price included?

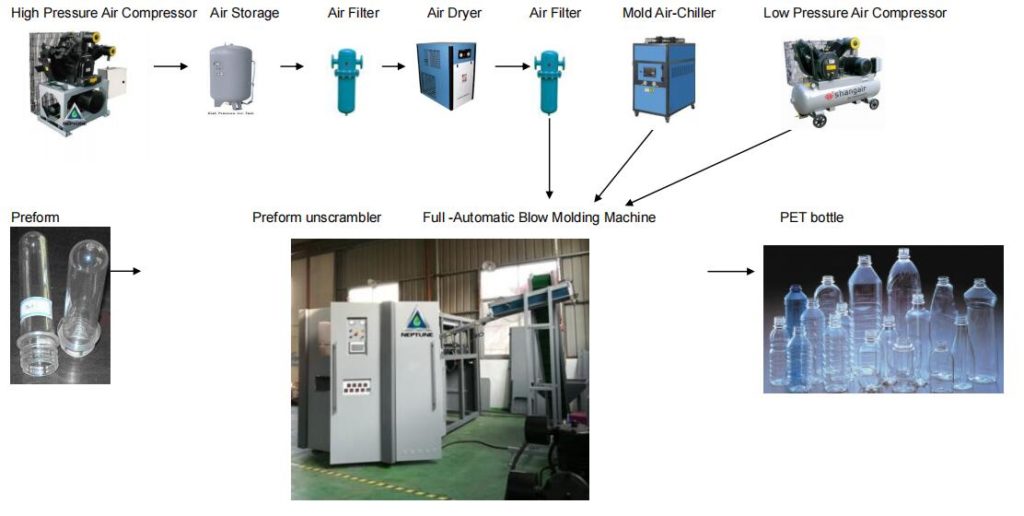

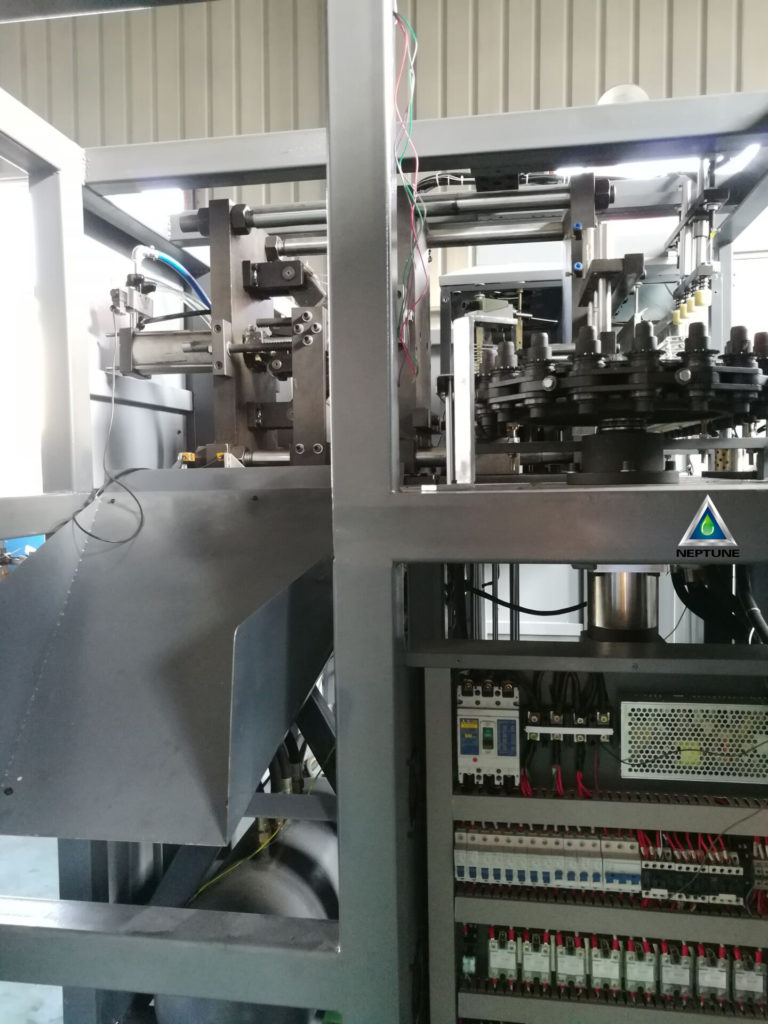

| 1 | BM-A4 Automatic Blow Molding Machine |

| 2 | BM-A4 Preform automatic unscrambler |

| 3 | 2.4m3/min ,30Kg HP Air Compressor |

| 4 | 2.0m3/min ,10Kg LP Air Compressor |

| 5 | 2.0m3/min ,30Kg Air Dryer(2 Air filters) |

| 6 | 0.6m3 30Kg Air Tank |

| 7 | 3HP Mould Air Chiller |

| 8 | High-low pressure tracheal connection |

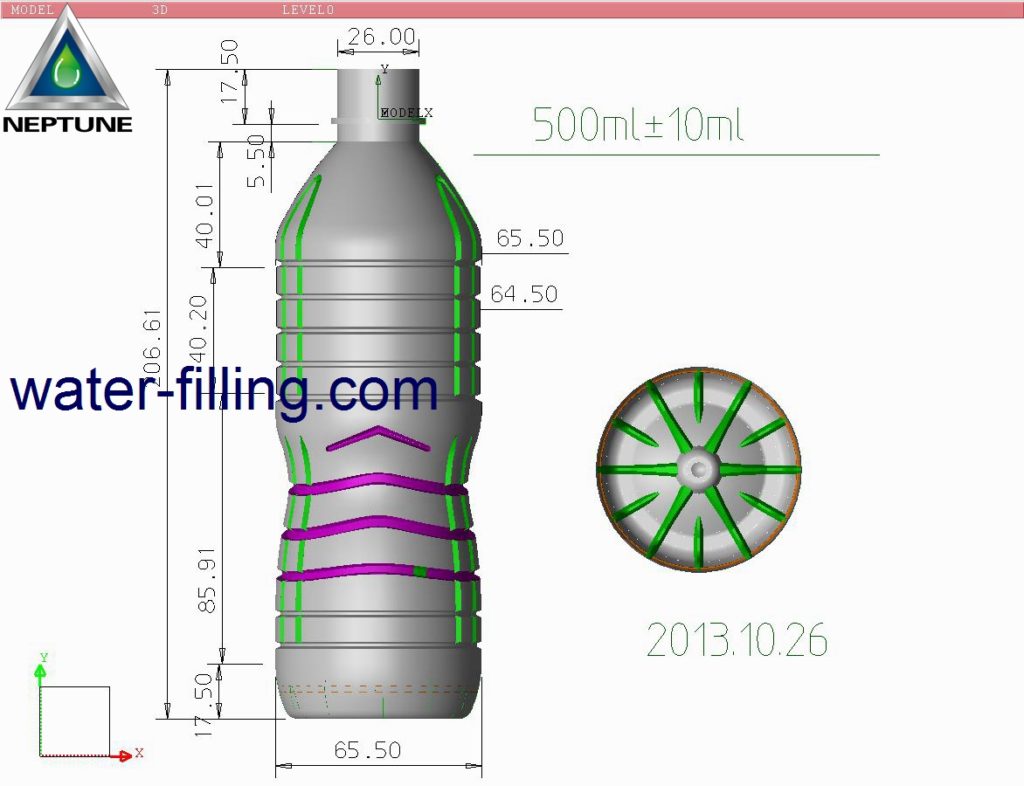

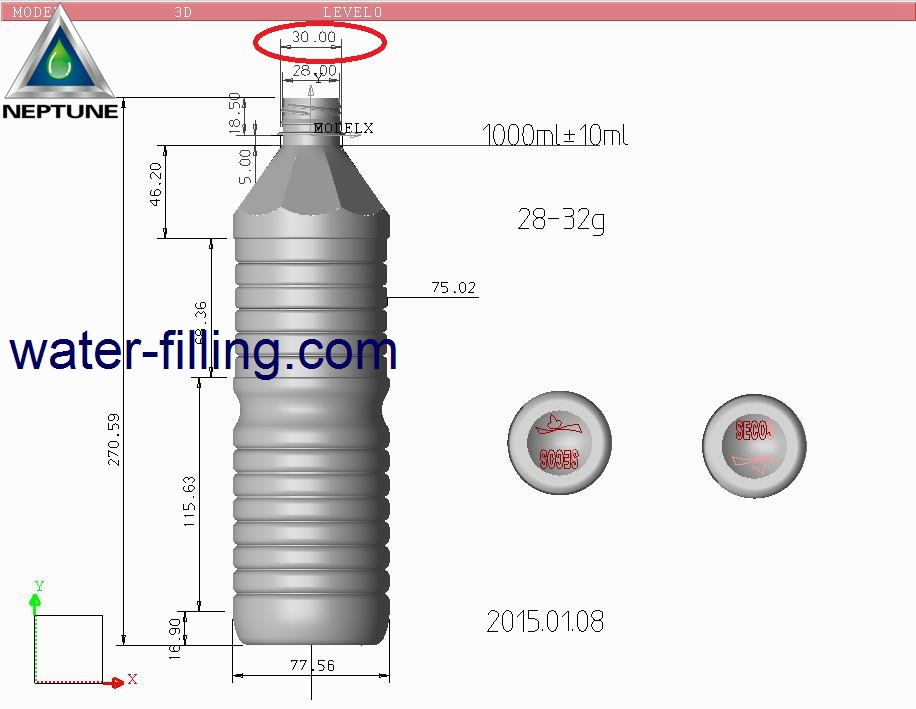

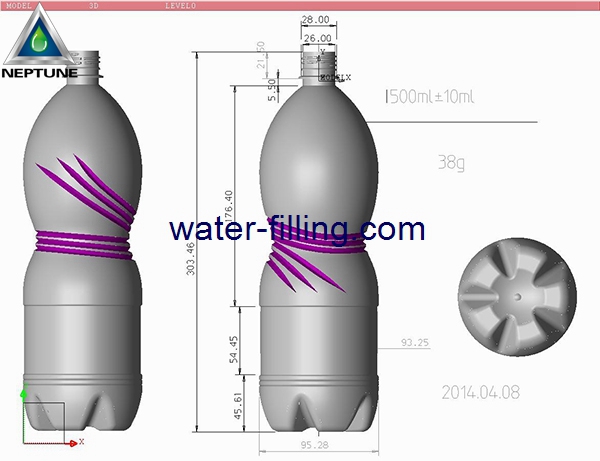

| 9 | Four cavity Blow Mold (250-2000ml) |

4000BPH Automatic PET bottle blow molding machine through a certain process blow the preform into plastic bottles. It is mainly used to produce the carbonated bottle, mineral water bottle, pesticide bottle oil bottle cosmetics, wide-mouth bottle for packaging beverage and water.

- Low than 0.1% damage bottle compare with traditional blowing machine.

- PLC controlled, which ensures accurate and reliable operation.

- Individualized operations and operation monitoring of the machine are realized by human-machine interface.

- Moving parts are connected with boundary lubricating bearings and straight guide rails( guiding blocks are made in Japan)

- Use Japanese-bumper is adopted for preventing mechanical bumping, which ensures low mechanical noise, low failure rate and long service life.

- Unique design of air blowing mechanism ensures very high output rate of finished products

Main parameter of 4000BPH Automatic pet bottle blowing machine

| Capacity of production | 4000 PCS/H |

| Bottle diameter | 20mm-100mm |

| Bottle Height | 50mm-350mm |

| Neck diameter | 15mm-38mm |

| Mold Cavity | 4cavities |

| Mold thick | 240mm |

| Volume of the bottle | 100ml-2000ml |

| Voltage | Can be setting |

| Rated Power | 49kw |

| Really use power | 10kw |

| LP air compressor | 2.0m3/min 1.0MPa |

| HP air compressor | 2.4m3/min 3.0MPa |

| Air dryer | 2.0m3/min 3.0MPa 1set |

| Cooling water | 15L/min |

| Main blower L*W*H | 1908*1858*1920mm |

| Main blower Weight | 3600kg |

| Preform unscrambler L*W*H | 276*106*186mm |

| Preform unscrambler Weight | 250kg |

| Metrials | PET preform |

Does the machine support different bottle sizes and shapes?

The bottle making machine is designed to support different bottle sizes and shapes. It offers flexibility in production, allowing for the manufacturing of bottles with varying volumes and designs. This adaptability is crucial for meeting the diverse demands of the market and catering to different product packaging requirements. Whether you need bottles for beverages, cosmetics, or other applications, the machine can be adjusted to produce a wide range of bottle sizes and shapes, providing versatility in your production capabilities.

4000BPH Bottle Blowing working Proess

- 1. Preforms unscrambler will automatic load the preform.

- 2. Machinery gear will transfers the preform to the heating oven

- 3. 10psc infrared lamps can be adjusted individually to control the temperature of oven. Preform automatically rotate can make sure preform heating evenly. The infrared thermometer inspecting temperature and will automatic adjust it by itself. All parameter can saw in the touch screen of the Neptune automatic blow molding machine and can easy setting. So that can always fit the best heating temperature

- 4. The temperature sensor can inspectst the temperature of the preforms. According compare with preset data, it will automatic feedback data to oven, and Oven will automatic adjust the temperature to the necessary temperature.

- 5. Preforms star-wheel will automatic transfer the after heated preform to the blow mold.

- 6. First, the preform will stretched in the mold. And then will blow into shape plastic bottle by high pressure air.

- 7. Machinery gear will transfers the plastic bottle to the air conveyor belt.

- 8. Air conveyor belt will directly send plastic bottle to washing filling capping machine.

video of the 4000BPH Bottle Blow Molding Machine

Is the machine fully automatic or semi-automatic?

The machine is fully automatic. It operates seamlessly with high automation, reducing the need for manual intervention. In a fully automatic bottle making machine, the entire production process, including material feeding, heating, molding, and bottle ejection, is carried out automatically. This level of automation enhances efficiency, reduces labor requirements, and ensures consistent and reliable production. The machine is equipped with advanced control systems, allowing it to perform multiple tasks without the need for constant manual supervision.

What is the energy consumption of the bottle making machine?

The bottle making machine has a main machine with a rated power of 49 kW, but in actual operation, it uses around 10 kW. Additionally, the high-pressure (HP) air compressor consumes 25 kW, and the low-pressure (LP) compressor consumes 15 kW. It’s essential to consider both the main machine’s power consumption and the power requirements of auxiliary components, such as air compressors, to assess the overall energy consumption of the bottle making process.

Chief Engineer Is Major shareholders, high quality machine with cheap price

It’s interesting to note that the Chief Engineer is a major shareholder in the company, which may indicate a strong commitment to quality and expertise in the field. Additionally, the combination of high-quality machines and competitive pricing suggests a focus on providing value to customers. Having a key figure like the Chief Engineer as a major shareholder could imply a hands-on approach to ensuring the excellence of the machines manufactured by the company.

Expertise and experience

Neptune machinery has a team of highly skilled and experienced engineers who have a deep understanding of blow molding technology and the needs of customers in blow mold machine industry. We design and build machines that are reliable and meet the exacting requirements of their customers.

refine on Quality materials and components

Neptune machinery uses high-quality materials and components in the construction of the blow molding machines, which helps to ensure that the machines are durable and able to withstand the rigors of the manufacturing process.

Less than 0.1% damage bottle

Neptune machinery pays close attention to every detail of their blow molding machines, from the design and construction to the final assembly and testing. This helps to ensure that the blowing machines are of the highest quality and meet the needs of customers.

Change mold to produce different bottle on one machine

You can easy change blow mold to produce different shape and volume plastic bottle on one machine with 1hour change mold time.

an bottle design as mold

An good bottle design will effect an bottled water company business. It is very important. Neptune have professional bottle design machine and experienced. Make sure final produce out bottle is completely same with bottle design. And bottle will have good quality. Make sure bottle mark clear and standing stable. Good structure bottle will standing stable. Then producing conveyor well. And final putting in shop and shelf is good.

The reasons why most bottled water companies produce their plastic water bottles in-house include:

- Optimizing Empty Space: Manufacturing the bottles on-site helps utilize empty spaces efficiently, reducing storage costs and maximizing available room.

- Preventing Bottle Damage: Empty bottles, especially without contents, can be prone to crushing if stacked. By producing them close to the bottling site, companies can minimize the risk of damage during transportation.

- Preventing Pollution: Extended exposure of empty plastic bottles to the air may lead to pollution. Manufacturing bottles on-site reduces the time they spend in an exposed state.

- Ensuring Sterility: The plastic bottle-making process involves heating preforms to high temperatures, ensuring the final product is sterile. This quick transition from production to bottling helps maintain a hygienic environment.

- Brand Protection: Famous bottled water companies often have unique and distinct bottle designs. In-house production safeguards the integrity of their brand by maintaining control over the manufacturing process.

- Cost Efficiency in the Long Run: While there may be initial setup costs, producing bottles in-house can be cost-effective over time. It provides greater control over production processes and minimizes dependency on external suppliers, potentially resulting in cost savings.

Why do most bottled water companies manufacture their own plastic water bottles

Is the machine easy to set up and operate?

Yes, the machine is designed for ease of setup and operation. It comes with user-friendly controls and interfaces, making it accessible even for operators with basic training. The straightforward design and automation features contribute to the simplicity of the setup process, ensuring that users can quickly get the machine up and running without extensive technical knowledge. Additionally, manufacturers often provide manuals and support to assist users during the installation and initial operation stages.

Does the machine come with installation and training services?

NEPTUNE MACHINERY offer installation and training services. When you purchase a bottle making machine, the manufacturer may provide the option for their engineers to assist with the installation process. This can include setting up the machine, connecting necessary components, and ensuring that it operates correctly.

Is there a warranty or after-sales support?

Yes, warranties and after-sales support are offerings for NEPTUNE bottle making machines. NEPTUNE MACHINERY provide a warranty 1YEAR to cover any defects in materials. After the warranty period expires, NEPTUNE still offer ongoing after-sales support. Include the availability of spare parts for replacement or repair, technical assistance, and guidance on maintaining and troubleshooting the machine.