FOB PRICE USD 16930

what The price Inclued?

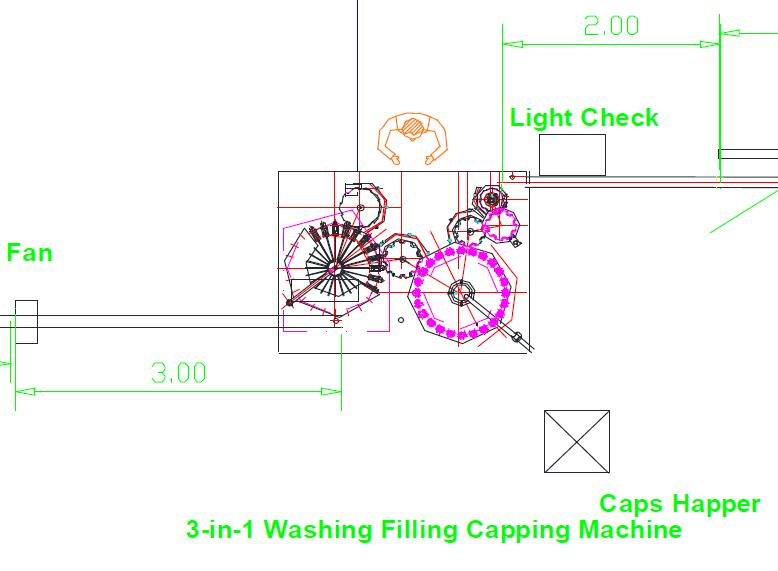

| NF 16-12-6 Washing-Filling-Capping (Three-in-One Unit) Machine, 1SET |

| Air compressor, 1SET |

| Cap automatic loading and feeding machine, 1SET |

| Convey System (2M Air conveyor,1psc air blower,2M conveyor,1psc motor), 1SET |

| Light check, 1SET |

It collects rotary washing, filling and capping together. It is driven by a transmission motor. It has advantages, such as high automation level, compact structure, beautiful appearance, convenient and simple operation, safe and reliable and adjustable continuous production capacity and others. It is an ideal no-gas liquid filling production equipment in the country. It is mainly suitable for filling and capping of round or square polyester bottles. According to the demands of different specifications of users, it is only changed a little in design to meet the user’s demands.

Capacity Scale of Bottle: 200—2000ml;

Height Scale of Bottle: 160mm-310mm;Drink Kind: Mineral Water, Pure Water, Fruit Juice, Wine and other no-gas liquid

Ideal for Your Industry:

This Water Bottling Machine Three in One stands out as the ideal no-gas water filling production equipment in the country. Specifically designed for filling and capping round or square polyester bottles, it adapts effortlessly to the demands of the beverage industry.

Tailored to User Demands:

Customization is at the core of our design philosophy. Whether your specifications require slight modifications or adjustments, we ensure that the machine aligns seamlessly with your unique production needs.

16/12/6 Washing-Filling-Capping (Three-in-One) Rotary water bottling machine made by our company is a new product which is developed on high-speed monoblock bottling machine. It just according market inquirement to adjust working head to reduce capacity of production to 4000 bottles per hour with less invest.

Advantages:

- High Automation Level:

- Experience unparalleled automation, reducing manual intervention and ensuring a smooth and efficient production line.

- Compact Structure:

- The machine boasts a compact design, saving valuable floor space while housing advanced functionalities.

- Beautiful Appearance:

- Aesthetic appeal meets functionality. The machine’s design not only enhances your production capabilities but also adds a touch of sophistication to your facility.

- Convenient Operation:

- User-friendly controls make operation a breeze. The machine is designed for easy handling, reducing the learning curve for your operators.

- Safe and Reliable:

- Prioritize safety with our machine. Built with reliable components and safety features, it ensures a secure working environment for your team.

- Adjustable Continuous Production:

- Adapt the production capacity to your needs. The machine allows for easy adjustment, providing flexibility in meeting varying production demands.

| MODEL | 16-12-6 |

| Production Capacity | 4000 Bottles per hour |

| Washing Head Quantity | 16 |

| Filling Valve Quantity | 12 |

| Capping Head Quantity | 6 |

| Filling Temperature | Normal temperature |

| Filling Type | Constant Pressure Filling |

| Main Motor Power | 2.2KW |

| Ordering-Cap Motor Power | 0.09KW |

| Cap Elevating Motor Power | 0.34KW |

| Washing Pump Power | 0.37KW |

| Liquid Inlet Pump Power | 0.55KW |

| Consume Water | 1.2T/h ( Un-including drink water) |

| Control Type | PLC |

| Central Diameter of Filling Valve | 480mm |

| Central Diameter of Capping Machine | 240mm |

| Central Diameter of Washing Machine | 640mm |

| Dimension | 2100 X 1500X2200mm |

| Net Weight: | 3500kg |

rotary rinser filler capper 3in1

A 3-in-1 water bottling machine refers to a multifunctional piece of equipment commonly used in the water bottling industry. This type of machine integrates three essential functions into a single unit, streamlining the process of water bottle production. The three primary functions include:

Rotary Rinser

Every washing head is moving together with the bottle. After 360 degree and back to next bottle. So every bottle washing is continued without waiting.

Rotary Filler

Every filling head is moving together with the bottle. After 360 degree and back to next bottle filling. So that every bottle filling is continued without waiting.

Rotary Capper

Every capping head is moving together with the bottle. After 360 degree and back to next bottle capping. So that every bottle capping is continued without waiting.

16-12-6 water Bottling Machine Working Process

Bottles are fed from conveyor chain into the filling machine monoblock via star wheel. Bottle clamp installed on the rotary wheel of the rinse will grip bottle mouth and make a 180° turn along a guide track to face the bottle mouth downward.

In designated section of the rinse, rinsing water will jet out from special nozzles to flush bottle inside wall. After rinsing and dripping, bottles gripped by bottle clamp will make another 180° turn along a guide track to resume bottle mouth facing up position.

Clean bottles are discharged out of the rinse by a star wheel to feed the filler. After entering the filler, bottles are retained by neck supporting carrier plates, which are actuated by bottle carrier mechanism to raise them to engage with filling valves.

Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process. Bottle carrier mechanism is lowered by a cam to disengage filled bottles with filling valves.

Then bottles are transferred into the capper by a neck handling star wheel. Anti-rotation blades on capping heads will seize the bottleneck to prevent it from rotation and hold it in a upright position.

The twist-on capping head will make revolving and rotating movement along with the machine to finish the complete capping process of cap picking, placing, twisting, and disengaging under the control of a cam. A discharge star wheel discharges finished bottles onto discharge conveyor belt to be conveyed out of the filling monoblock.

cap Automatic loading and feeding equipment

It come with the 16-12-6 water bottling machine, price already included.

Key Features:

🚀 Automated Cap Loading:

- Say goodbye to manual cap handling. Our equipment automates the cap-loading process, significantly reducing labor and increasing overall efficiency.

🔧 Seamless Conveyor Integration:

- Enjoy a seamless transition from cap loading to the filling machine. The equipment features an automatic conveyor system that ensures a continuous flow of caps to meet your production demands.

🌐 Screw Cap Types:

- Designed to accommodate various screw cap types, our equipment is versatile, allowing you to use it with different styles and sizes of water bottle screw caps.

How It Works:

- Cap Loading: The Automatic Cap Loading and Feeding Equipment efficiently loads caps from the storage area onto the conveyor system.

- Automatic Conveyance: Caps are automatically conveyed from the loading station to the filling machine, ensuring a smooth and uninterrupted process.

- Seamless Integration: The equipment seamlessly integrates with your existing production line, enhancing overall workflow and reducing bottlenecks.