FOB PRICE $ 5160

What this price included?

- Filter tank stainless steel

- Pipe stainless steel

- RO membrane (6psc 4040)

- 3000LPH Quartz sand filter

- 3000LPH Active carbon filter

- 3000LPH Precision filter

- 3TON Water pump

1500LPH Industrial reverse osmosis system and make it easy to start produce pure drinking water, Its pure water outlet production 1500 liter per hour. You can running it 23.5hours while only half a hour to backwash it. It is all-in one water purification solution.

1500LPH (liters per hour) industrial reverse osmosis system is a device that uses reverse osmosis technology to purify water by removing contaminants and impurities from it. The process involves passing the water through a semi-permeable membrane, which removes a wide range of contaminants, including bacteria, viruses, heavy metals, and other dissolved solids.

Industrial reverse osmosis system are commonly used in a variety of applications, including residential, commercial, and industrial settings. They are often used to produce high-quality drinking water, as well as for use in manufacturing, food and beverage processing, and other industries where purified water is required.

Industrial reverse osmosis system typically consist of several key components, including a pre-treatment system, a pump, RO membrane and post-treatment system if treatment special raw water. The pre-treatment system is used to remove larger particles and contaminants from the water before it enters the RO system. The pump is used to force the water through the membrane, and the post-treatment system is used to add minerals or other substances back into the water to improve its taste and pH balance.

| Capacity purified water | 1500 Liter per hour |

| Cost raw water | 2000 Liter per hour |

| RO membrane | 6 psc 4040 |

| Quartz sand filter | Flow: 3 ton per hour Media: 150 kg carbon |

| Active carbon filter | Flow : 3 ton per hour Media: 80 kg of quartz sand |

| Precision filter | 5 set PP filter PP30-40 Flow 3M3 |

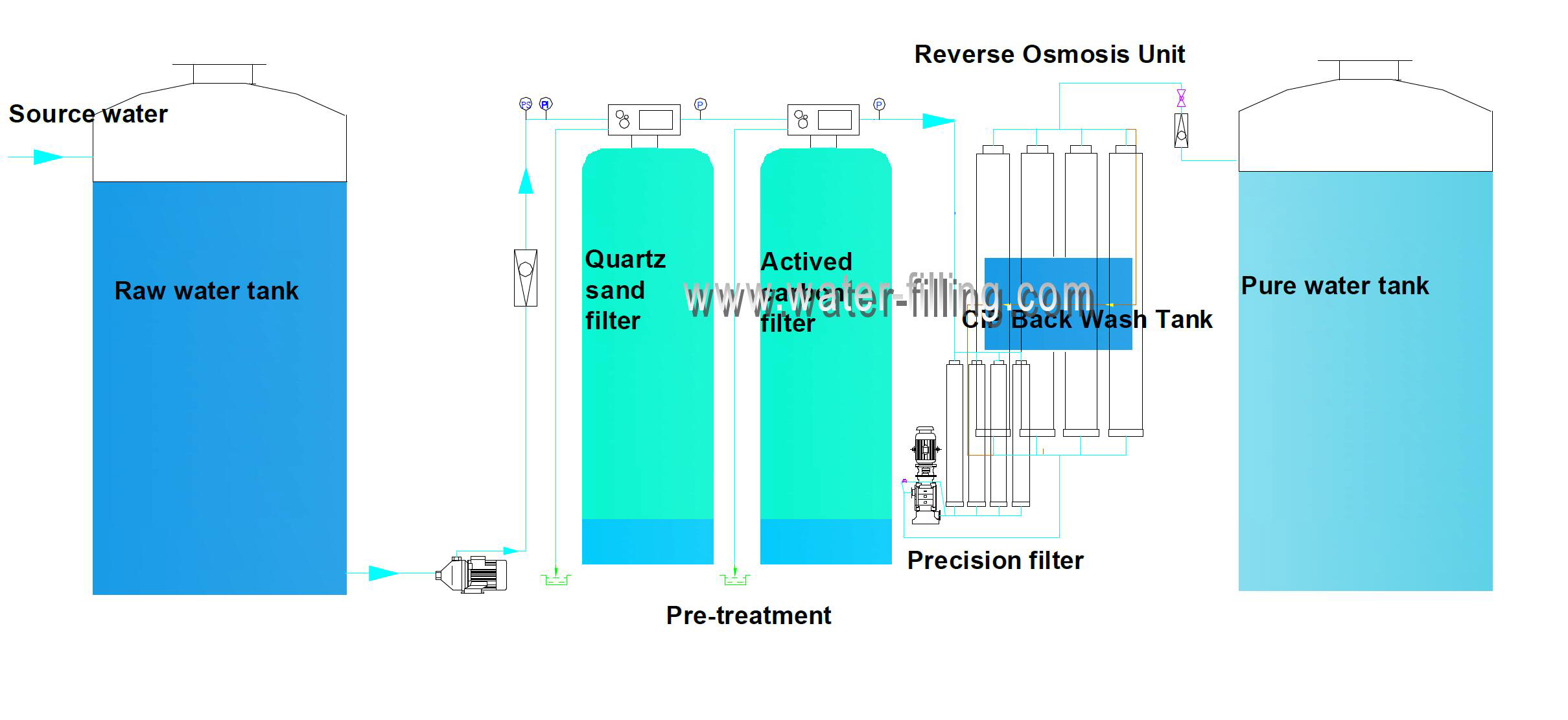

how Industrial reverse osmosis system make pure water?

Technique Process 1500LPH Industrial reverse osmosis system

The technique process for a 1500LPH Industrial reverse osmosis system typically involves the following steps:

- Pre-treatment: The water is pre-treated to remove larger particles and contaminants, such as sand, dirt, and other suspended solids. This is typically done using a sediment filter, a sand filter, or a multimedia filter.

- Pumping: The water is then pumped through the RO system using a high-pressure pump. The pressure is used to force the water through the semi-permeable RO membrane, which removes a wide range of contaminants and impurities.

- RO Membrane : As the water passes through the RO membrane, it is separated into two streams: a purified water stream and a concentrate stream. The purified water stream is collected on the other side of the membrane and can be used for a variety of purposes, depending on the specific needs of the user. The concentrate stream contains the contaminants and impurities that are removed from the water and is typically discarded.

- Post-treatment: The purified water may be treated with additional chemicals or minerals to improve its taste and pH balance. This is typically done using a post-treatment system, which may include a chemical dosing system, a pH adjustment system, or a mineralization system.

- Collection and storage: The purified water is then collected and stored in a storage tank or other container for use or further processing.

It is important to note that the specific technique process for a 1500LPH Industrial reverse osmosis system may vary depending on the specific needs and requirements of the user, as well as the specific features and capabilities of the machine.

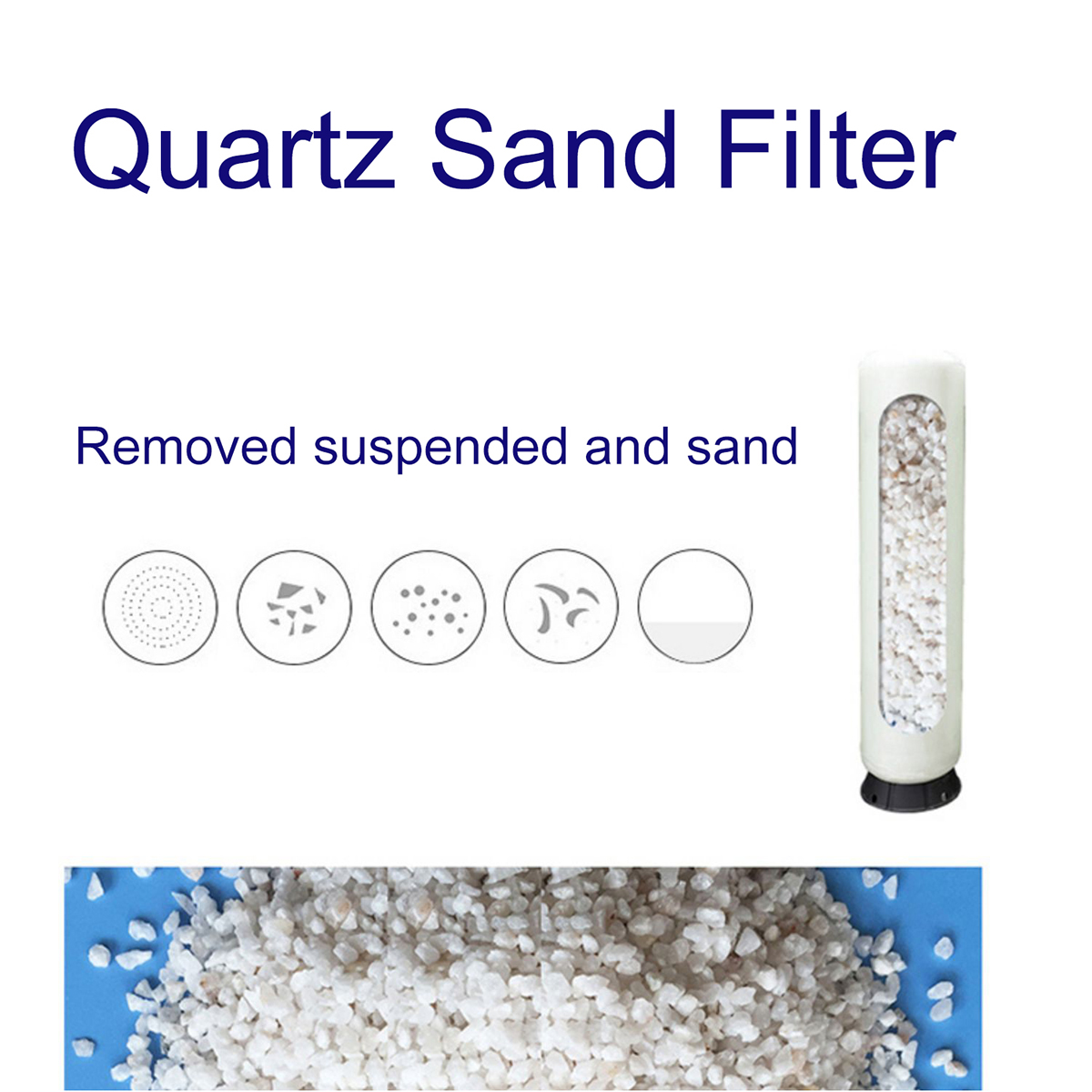

Quartz Sand Filter, 1th Prepare Filter For RO Device

In order to protect the back-end filters, we adopt the quartz sand filter .

Quartz sand filter (Optional manganese sand)Removed big suspendid of raw water. Remove different types of particles, such as suspended solids (turbidity), colloidal compounds and etc.

Quartz sand filter will reduce the load on the back-end filters Water production index: SDI<1-3.

After a period of time, the filter will be saturated. In order to restore its function, the filter needs backwashes. In order to achieve its best results, the efficient backwash needs taking 20-30min. This filter is fitted with two diffusers, a

manhole for discharge media.

Activated Carbon Filter, 2th Prepare Filter For RO Device

In order to protect the back-end filters, we adopt the active carbon filter .

Active carbon filter remove of organic substance and heavy metal element, suspended solids and etc. It can effectively reduce the level of COD and improve the taste of water.

With a valve operating system, pipeline system, containing the manhole, hand hole, the upper and lower water distribution devices, media, pressure.

After a period of time, the media will be saturated and it needs backwashes. In order to achieve its best results, the efficient backwash needs taking 20-30min. This filter is fitted with two diffusers, a manhole for load media

Precision Filters, 3th Prepare Filter For RO Device

Prevent the particles entering the membrane, scratched the surface of the membrane. In the normal operating condition, the filter can maintained for 3 mouth. The filter structure for fast replace.

Manufacture of high quality PVC material. Filter holder containing a fixed The 5μm PP filter is most commonly used for dealing the pure water. It is generally believed that the harmful particles and bacteria are larger than 0.22μm.

In order to prolong the life of RO membrane, the whole system adopts one set of stainless pp filter. The polypropylene microporous filter cartridges with the length of 40 inch in 5μm filters respectively. The 5μm filter acts as the protector of the RO membrane, filtering the vast majority of particles in the water, which eases the load of RO membrane and prolong its life.

The filter cartridges are for one-time use, as the particles retained in the gap of microporous filtering film is hardly removed by rinsing with acid-base. After a period of time, the filter cartridge needs to be replaced. The structure of them makes replacement of cartridge convenient. This apparatus contain filtration cartridges and stainless support layers. The support layer is made of stainless steel 304, with the advantages of compact structure, beautiful shape, high flux, good filtration accuracy and etc.

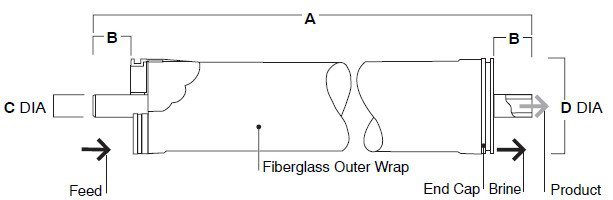

RO membrane

RO membranes auto wash and manual wash

RO membranes manual wash with medicine

Pure water high water level auto stop, low water level auto start

Multi-phases pump protected without water

Protected when no power, poor power, over electrical current, short circuit, circuit breaker, leakage protection.

The RO device removes the hydronium, organic substance, colloid, bacteria and other impurity by the method of membrane. And the water can be desalted and purified. The theory is as follows. The treated water and the untreated water are separated by the membrane; the treated water osmoses to the untreated water. There is osmotic pressure between the two. If the pressure is added to the untreated water and the pressure of the untreated water is bigger than the osmotic pressure, the water of the untreated water osmoses to the opposite position of the water. This applies the reverse osmosis to the desalted water. That is to say the untreated water is purified into the pure water through the RO membrane under adequate pressure. The left water which can not osmosis through the membrane contains a lot of solute and suspended substance, and it will be drained out as waste water.

The water must be pretreated before entering into the RO system, or it will bring damage to the RO membrane.

The RO system not only can be used for desalination, but also for filtering the organic substance and bacteria.

The production of water is monitored by the liquid crystal display conductivity meter.

The RO system needs be cleaned timely, including the stainless steel pump, filter, disinfectant tank, valve and other components.

Commonly, the RO system should work once every day. If it does not work in one week, it must be protected by some measures, or the service life of the membrane will be serious affected.

RO device employs low pressure large flux membrane made by American Company. The type is American 4040 Ro Memebrane, and it has four of them. The membranes can serve for years in good maintenance. This instruction explains the details of operation and maintenance methods. The RO device removes the hydronium, organic substance, colloid, bacteria and other impurity by the method of membrane. And the water can be desalted and purified. The theory is as follows. The water and the solution are separated by the membrane; the water osmoses to the solution. There is osmotic pressure between the two. If the pressure is added to the solution and the pressure of it is bigger than the osmotic pressure, the water of the solution osmoses to the opposite position of the water. This applies the reverse osmosis to the desalted water. That is to say the raw water is purified into the pure water through the RO membrane under adequate pressure. The left water which can not osmosis through the membrane contains a lot of solute and suspended substance, and it will be drained out as waste water. This principle makes RO device.