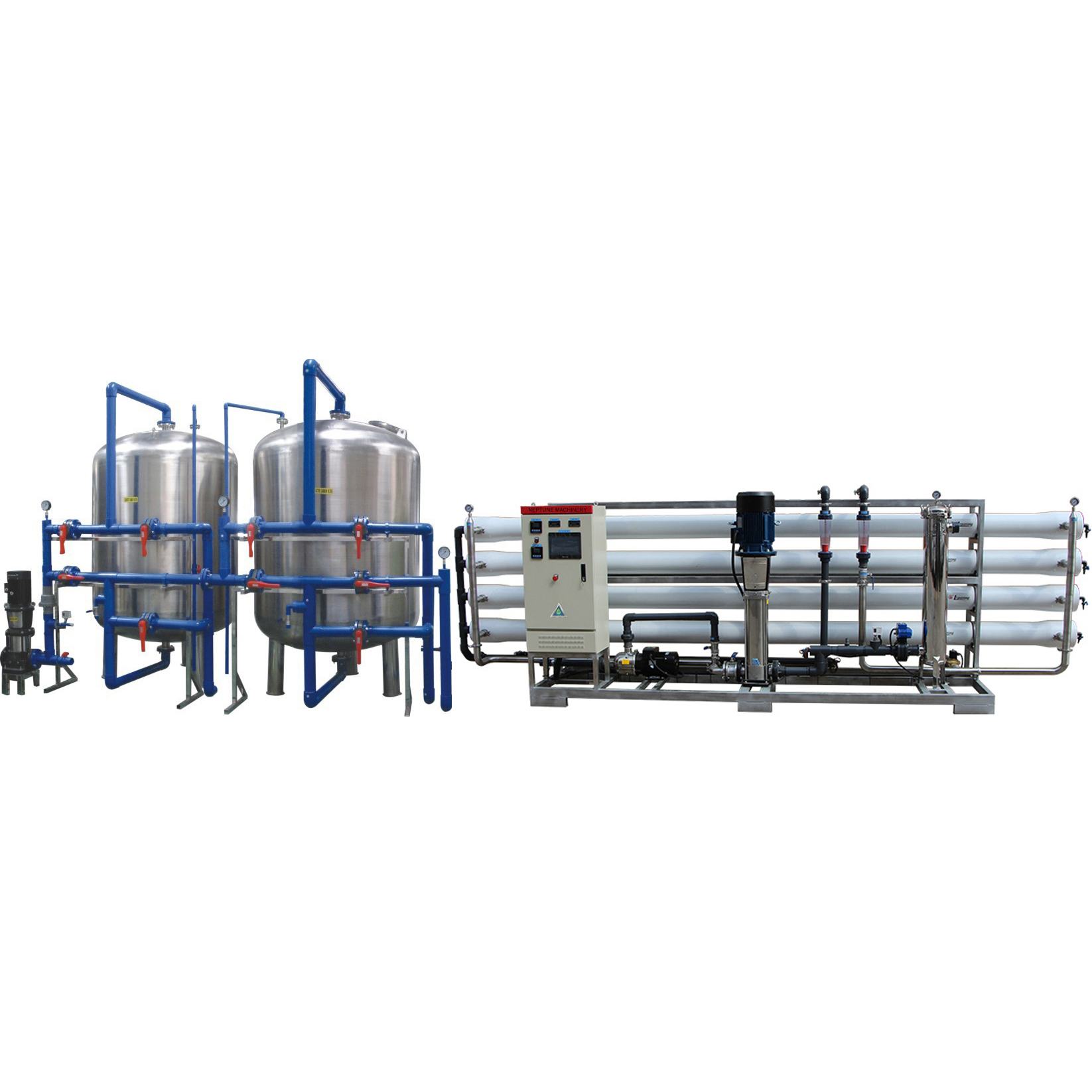

FOB PRICE $30,640

What this price included?

CDL 65-20 Original pump /1SET

15000LPH Quartz Sand Filter/1SET

15000LPH Activated Carbon Filter/1SET

15000LPH Precision filter (15set 5u*1000 PP filter)/1SET

10T/H RO unit [9PSC 8040 ]( ALL PIPE S.S304)/1SET

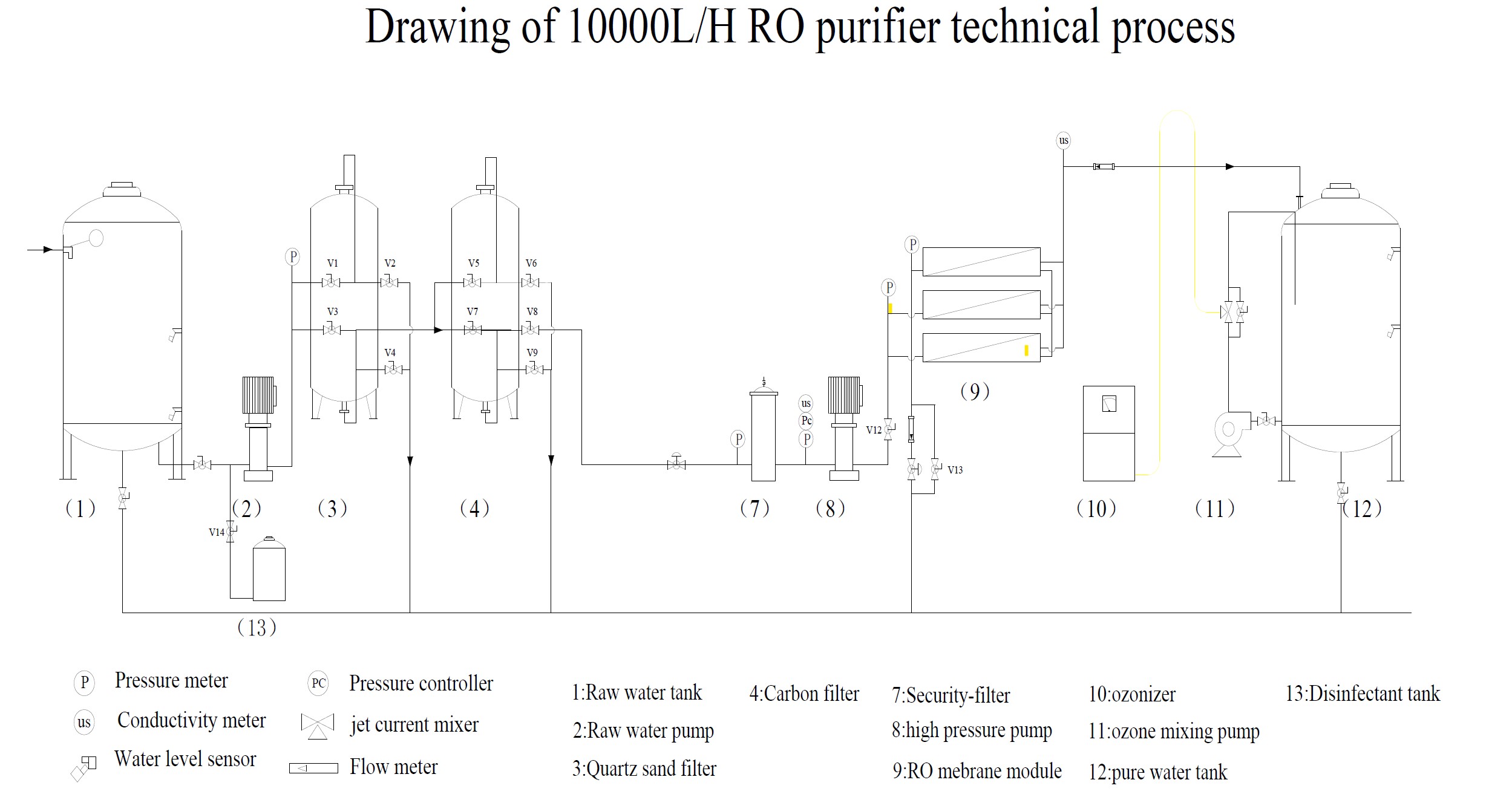

10000LPH RO water treatment plant made use of reverse osmosis technology to remove impurities from water. RO is a process that uses a semi-permeable membrane to remove dissolved solids, such as salts and minerals, from water. It is often used in the treatment of seawater, brackish water, and municipal drinking water.

- RO water treatment plant Specifications:

- Manufactured by Neptune Machinery Company.

- Capacity: 10,000 liters per hour.

- Reverse osmosis technology to remove impurities from water.

- RO Process:

- Inlet raw water: 12,500 liters per hour.

- Outlet pure water: 10,000 liters per hour.

- Waste water: 2,500 liters per hour.

- Pre-treatment Process:

- The pre-treated water passes through a series of filters, including a sand filter and an activated carbon filter, to remove smaller particles and organic contaminants.

- Reverse Osmosis Process:

- The membrane removes dissolved solids and contaminants, resulting in purified water. Purified water is collected on one side of the membrane, while contaminants are flushed away.

- Efficiency and Energy Considerations:

- RO plants are highly efficient in producing high-quality purified water.

- Acknowledges that RO plants require a significant amount of energy to operate.

- Maintenance and Fouling Prevention:

- Recognizes the propensity of RO plants to fouling, which can reduce efficiency over time.

- Emphasizes the importance of regular cleaning and maintenance of filters and membranes.

- Back Wash System:

- Recommends opening the backwashing system for 10 minutes after daily use to clean the RO membrane, ensuring a longer lifespan.

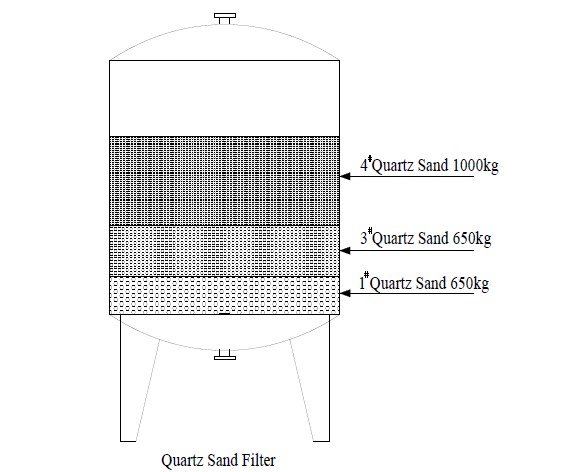

15000LPH Stainless steel quartz sand filter

Tank Material: SUS304

Filter material: refined quartz sand 1:1000kg 2:650kg 3. 650kg

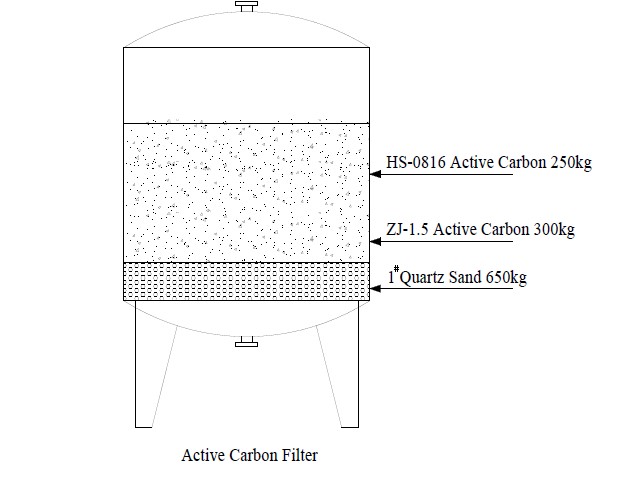

15000LPH Stainless steel actived filter

Tank Material: SUS 304

Active carbon: 550kg,

Quartz sand: 650kg

9PSC USA company 8040 RO membrane

10 ton per hour RO water treatment plant process

Industrial reverse osmosis (RO) water treatment systems are used to produce high-purity water for a variety of applications, including power generation, pharmaceutical manufacturing, and food and beverage processing. The process of RO water treatment involves several steps:

- Pretreatment: Water is typically pretreated to remove any large particles or contaminants that could clog the RO membrane. This may include the use of screens, sediment filters, and chemical treatment.

- An active carbon filter, also known as a carbon filter or activated carbon filter, is a type of water filter that uses activated carbon to remove contaminants and impurities from water. Activated carbon is a porous, highly adsorbent material that is effective at removing a wide range of contaminants, including chlorine, chloramines, VOCs (volatile organic compounds), and many other dissolved contaminants.

- A precision filter is a type of filter that is designed to remove very small particles and contaminants from water. Precision filters are typically used in reverse osmosis (RO) systems to long the RO membrane life.

- RO membrane: The water is then passed through the RO membrane, which is a thin film composite (TFC) membrane made of layers of semi-permeable material. The RO membrane is designed to remove a wide range of contaminants, including dissolved solids, bacteria, and viruses, by forcing the water through the membrane under pressure.

- Product water: The water that passes through the RO membrane is known as the “product water,” and it is typically of very high purity.

- Reject water: The water that does not pass through the RO membrane is known as the “reject water,” and it contains the contaminants that were removed from the feed water.